french door seal strip factory

Sep . 23, 2024 01:17 Back to list

french door seal strip factory

The Importance of Quality French Door Seal Strips A Look into Manufacturing

French doors are a popular architectural feature, known for their elegant design and ability to connect indoor spaces with outdoor views. However, to maintain their functionality and aesthetic appeal, proper sealing is essential. This is where high-quality French door seal strips come into play, ensuring energy efficiency, security, and comfort in homes and commercial spaces. In this article, we will explore the significance of these seal strips and the manufacturing processes involved in their production.

The Role of Seal Strips

Seal strips are crucial in preventing drafts, moisture, and pests from entering through the gaps around French doors. A well-designed seal acts as a barrier, ensuring that homes remain cozy during chilly winters and cool during sweltering summers. Furthermore, a proper seal enhances energy efficiency by reducing the workload on heating and cooling systems, leading to lower energy bills and a smaller carbon footprint.

In addition to energy efficiency, seal strips also contribute to the security of a property. They make it more difficult for intruders to gain access through poorly sealed doors. High-quality seal strips create a tight fit, ensuring that doors cannot be pried open easily.

Manufacturing Quality Seal Strips

The production of French door seal strips involves several critical steps to ensure that the final product meets the highest standards of quality and durability. Understanding these processes provides insight into why choosing products from a reputable factory is essential.

french door seal strip factory

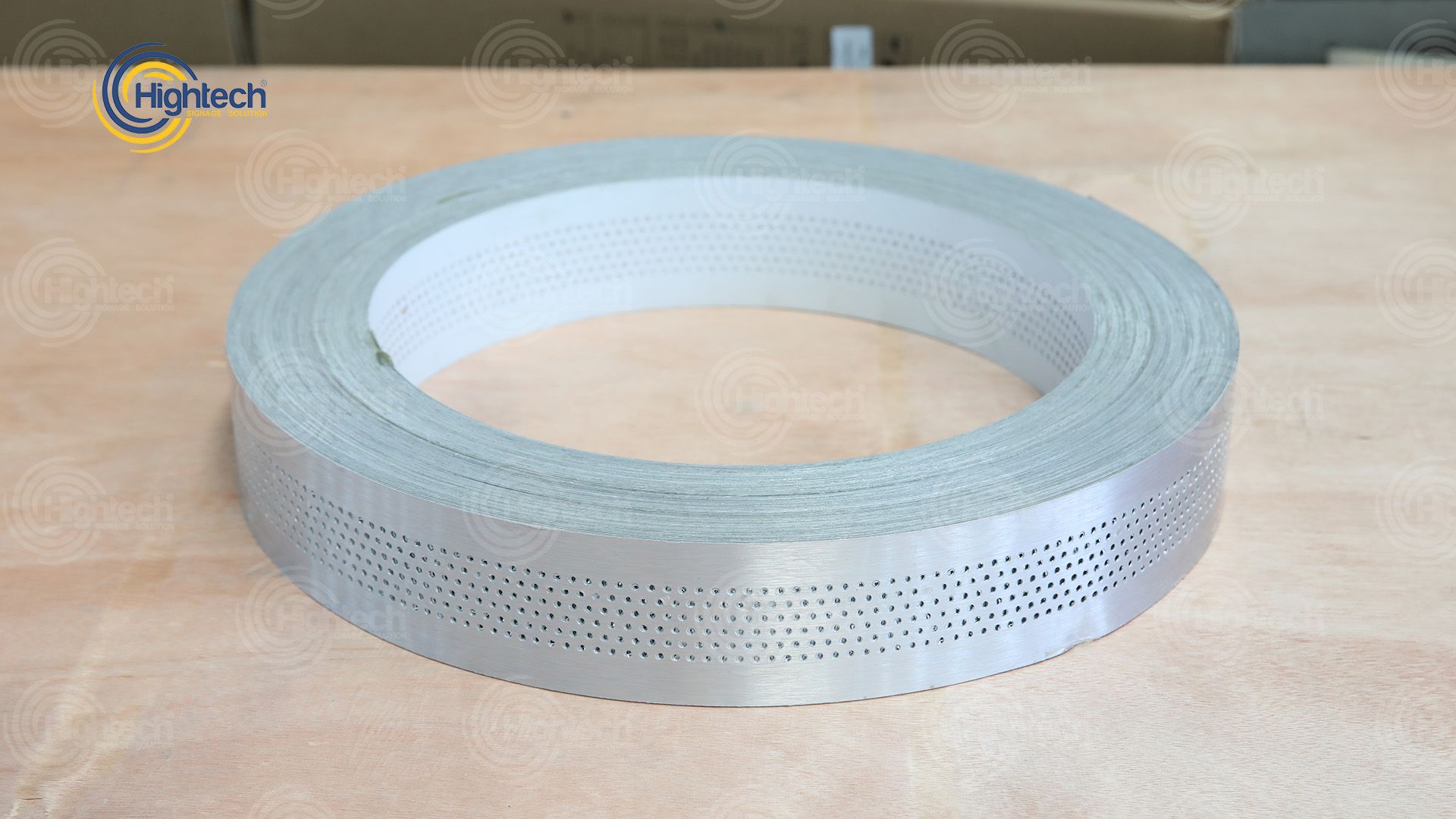

1. Material Selection The first step in manufacturing seal strips is selecting the right materials. Most seal strips are made from rubber, silicone, or foam. Each material has unique properties, such as resistance to weather changes, durability, and flexibility. For instance, silicone seal strips are known for their ability to withstand extreme temperatures, making them ideal for outdoor applications.

2. Molding and Shaping Once the materials are selected, they are molded into the desired shapes. Advanced machinery is utilized to ensure precision and consistency in size and contour, which is critical for effective sealing.

3. Quality Control After molding, each batch of seal strips undergoes rigorous quality control testing. This includes checking for flexibility, tensile strength, and overall performance in various weather conditions. Factories often use state-of-the-art testing equipment to ensure the products meet industry standards.

4. Customization Options Many manufacturers provide customizable seal strip solutions to meet specific customer needs. This flexibility allows businesses to cater to unique architectural requirements, ensuring that the seal strips fit perfectly and function effectively.

5. Sustainability Practices As the world becomes more environmentally conscious, many factories are adopting sustainable manufacturing practices. This includes using recyclable materials and minimizing waste during production.

Conclusion

The significance of high-quality French door seal strips cannot be understated. They play a pivotal role in enhancing energy efficiency, improving security, and increasing comfort within a space. By understanding the manufacturing processes and the care that goes into creating these essential components, consumers can make informed choices when selecting seal strips for their French doors. Investing in quality products from reputable factories not only ensures effectiveness but also contributes to longer-lasting home improvements.

-

High Quality LED Split Neon – Leading Exporter & Factory of Innovative LED Split Neon Products

NewsJun.24,2025

-

Plastic + Aluminum Channel Aluminum Groove Belt Supplier - Premium Channel Edge Products Exporter

NewsJun.10,2025

-

High Quality Chrome Trim Strip Leading Manufacturer & Custom Factories Service

NewsJun.10,2025

-

Premium Car Trim Strip – Leading Car Moulding Trim Strip Exporters & 3 Car Moldings Trim Strip Manufacturers

NewsJun.10,2025

-

Premium White Transparent PVC Adhesive Strips Strong Bond & Waterproof

NewsJun.10,2025

-

Premium Plastic Aluminum Channel Groove Belt for Durability

NewsJun.10,2025