water stop rubber seal strip manufacturer

ታኅሣ . 29, 2024 18:39 Back to list

water stop rubber seal strip manufacturer

The Importance of Water Stop Rubber Seal Strips A Comprehensive Overview

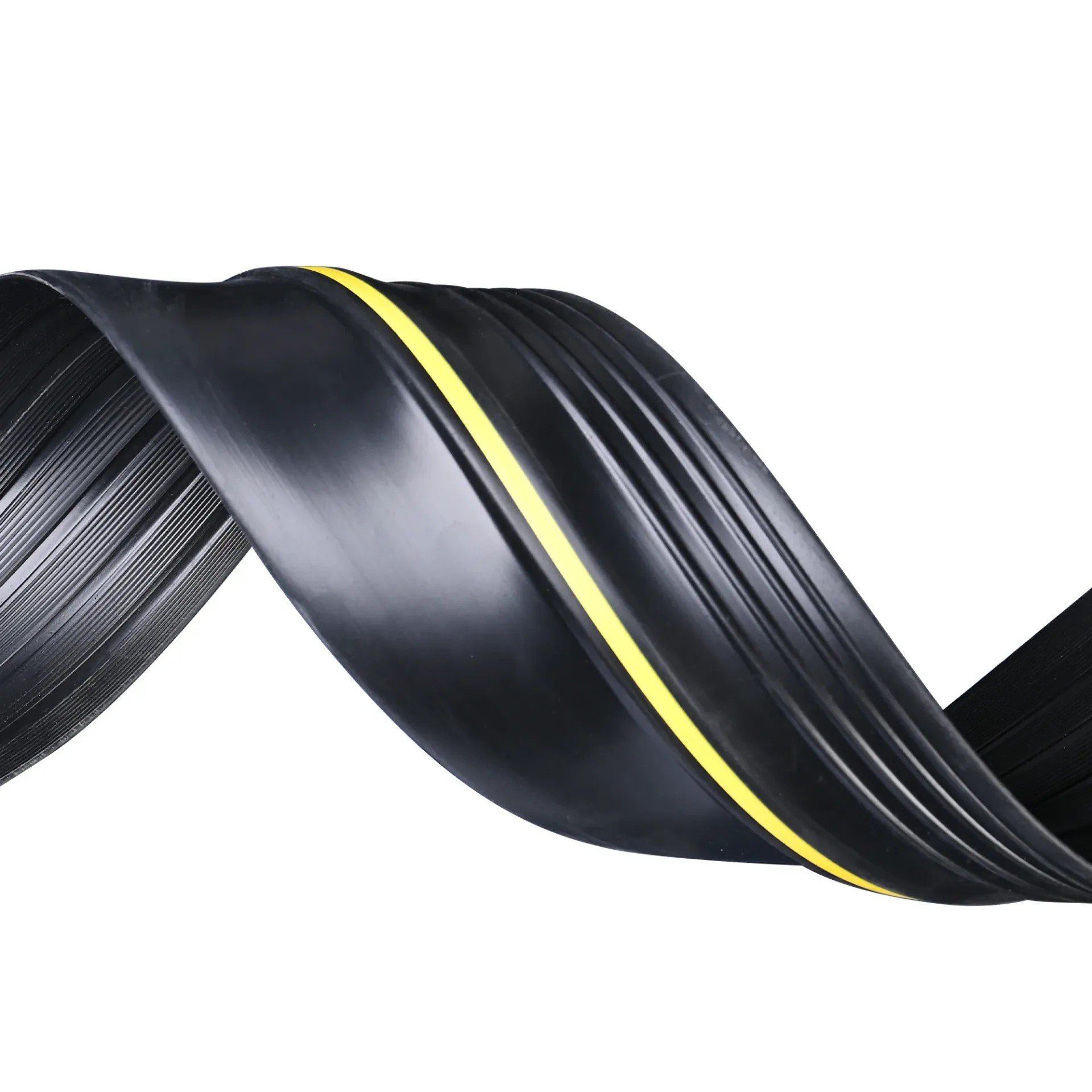

In various industries such as construction, manufacturing, and automotive, the need for effective sealing solutions is paramount. One such solution that stands out due to its versatility and effectiveness is the water stop rubber seal strip. As the name suggests, these innovative strips are designed to prevent the ingress of water, thereby protecting structures from potential damage. This article delves into the manufacturing process, characteristics, applications, and benefits of water stop rubber seal strips.

Manufacturing Process

The manufacturing of water stop rubber seal strips typically involves the use of high-quality rubber materials, which are capable of withstanding different environmental conditions. The process begins with the careful selection of raw materials, primarily synthetic rubber compounds that exhibit excellent elasticity, durability, and resistance to water and chemicals.

Once the materials are chosen, they undergo a series of processes, including mixing, molding, and curing. The mixing process involves combining various additives and fillers to enhance the rubber's properties, such as flexibility and temperature resistance. After mixing, the rubber is molded into the desired shape and size using precision molds. Finally, the curing process ensures that the rubber solidifies to achieve optimal strength and performance.

Manufacturers often adhere to strict quality control measures during production to ensure consistency and reliability in their products. This is crucial as water stop rubber seal strips are used in critical applications where the integrity of a structure is at stake.

Key Characteristics

Water stop rubber seal strips are characterized by several key properties that make them ideal for sealing applications 1. Water Resistance As their primary function is to prevent water infiltration, these seals are designed to withstand prolonged exposure to moisture. 2. Durability High-quality rubber compounds provide excellent resistance to wear and tear, ensuring a long service life even in harsh environments. 3. Elasticity The flexibility of rubber allows the seal to adapt to different surface conditions, providing a snug fit that enhances sealing effectiveness. 4. Chemical Resistance Many water stop seals are formulated to resist chemicals, making them suitable for industrial applications where exposure to various substances is common.

water stop rubber seal strip manufacturer

Applications

Water stop rubber seal strips find applications across a broad spectrum of industries

- Construction In building foundations, basements, and retaining walls, water stop strips are critical for preventing water ingress. They are installed in construction joints and expansion joints to ensure a watertight seal. - Automotive In vehicles, these seals are used to prevent water from entering critical areas, such as doors, windows, and trunk spaces, ensuring a dry and safe environment for passengers and cargo. - Manufacturing Industrial equipment often requires sealed enclosures to protect sensitive components from moisture and contaminants. Water stop seals help maintain the integrity of these systems. - Marine In boats and ships, water stop seals are essential for keeping interiors dry and preventing water damage, particularly in areas prone to leaks.

Benefits

The use of water stop rubber seal strips offers numerous advantages

- Cost-Effectiveness By preventing water damage, these seals can save businesses significant repair costs in the long run. - Enhanced Safety In construction and automotive applications, preventing water ingress helps maintain structural integrity, thereby enhancing safety for users. - Customizable Solutions Manufacturers often provide customizable seal strips to meet specific requirements, ensuring that customers receive the best solutions for their needs.

Conclusion

In conclusion, water stop rubber seal strips play a vital role in protecting structures and equipment from water damage across various industries. Their effective sealing capabilities, coupled with their durability and versatility, make them an essential component in modern manufacturing and construction practices. As the demand for reliable sealing solutions continues to grow, manufacturers are poised to innovate and improve the performance of water stop rubber seal strips, ensuring that they remain a cornerstone of water management and prevention technologies.

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025