Aluminum Plastic Edge Strip Manufacturing Facilities Overview and Key Insights

نوفمبر . 25, 2024 09:24 Back to list

Aluminum Plastic Edge Strip Manufacturing Facilities Overview and Key Insights

The Rise of Aluminum-Plastic Edge Strip Factories

In recent years, the demand for aluminum-plastic edge strips has surged, leading to the establishment of numerous specialized factories worldwide. These edge strips, composed of aluminum composite materials, have become essential in various industries, especially in furniture manufacturing, interior design, and construction. Their versatility, durability, and aesthetic appeal make them a preferred choice among designers and consumers alike.

One of the primary reasons for the increasing popularity of aluminum-plastic edge strips is their unique composite structure. The combination of aluminum and plastic offers a lightweight yet sturdy solution that can withstand wear and tear. These strips are resistant to scratching, impact, and moisture, making them ideal for high-traffic areas and environments exposed to varying weather conditions. Additionally, the edge strips can be manufactured in various colors and finishes, providing countless design options that cater to different tastes and aesthetics.

The emergence of factories dedicated to producing aluminum-plastic edge strips has been fueled by technological advancements. Innovative manufacturing processes, such as extrusion and lamination, enable factories to produce high-quality edge strips efficiently. These processes ensure that the strips maintain consistent thickness and smooth finishes, essential for seamless integration into various applications. Moreover, advancements in machinery have reduced production times and costs, allowing manufacturers to meet the growing market demand effectively.

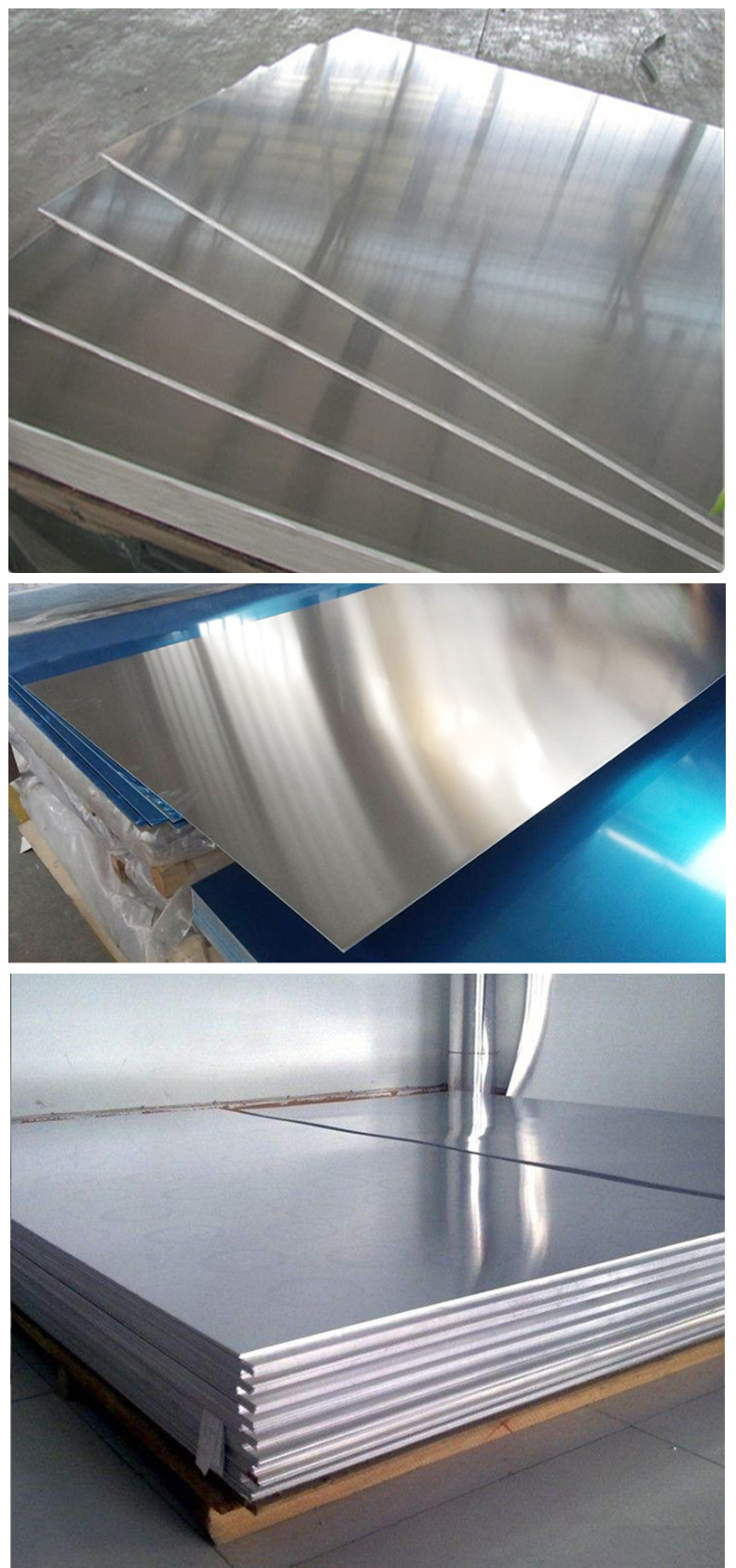

aluminum-plastic edge strip factories

Environmental sustainability has also played a significant role in the growth of aluminum-plastic edge strip factories. Many manufacturers are adopting eco-friendly practices, utilizing recyclable materials and minimizing waste in their production processes. As sustainability becomes a significant concern for consumers and businesses alike, the demand for environmentally friendly products, including aluminum-plastic edge strips, is on the rise. Factories that prioritize sustainable manufacturing processes are not only appealing to eco-conscious consumers but also benefiting from reduced operational costs and enhanced brand loyalty.

The global market for aluminum-plastic edge strips is highly competitive, with numerous factories vying for prominence. Many of these manufacturers are focusing on research and development to create innovative products that stand out. Customization options, such as unique shapes and sizes, are increasingly being offered to meet specific client needs. This trend is particularly evident in the furniture industry, where bespoke designs are highly sought after.

In conclusion, the rise of aluminum-plastic edge strip factories is a testament to the material's growing significance in various industries. With their durability, aesthetic versatility, and sustainable production practices, aluminum-plastic edge strips are set to become a staple in modern design and construction. As the market continues to expand, factories that innovate and adapt to changing trends will likely thrive, further solidifying aluminum-plastic edge strips as a key component in the design landscape. The future holds promising potential for this burgeoning industry, making it an exciting space to watch.

-

Hi flo Oil Filter H F155 for KT M 250 EXC Racing 2003-2006, OEM Quality

NewsJul.24,2025

-

Top LED Neon Rope Light Outdoor Companies – Durable & Weatherproof Solutions

NewsJul.23,2025

-

Top Window Seal Strip Adhesive Companies for Quality Sealing Solutions

NewsJul.22,2025

-

HighTech Injection LED Module Size 6414 - Efficient, Durable Lighting

NewsJul.22,2025

-

Top Window Seal Strip Adhesive Companies | Durable Weatherproof Seals

NewsJul.21,2025

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025