glazing seal strip

dec . 11, 2024 08:09 Back to list

glazing seal strip

Understanding Glazing Seal Strips Importance, Types, and Applications

Glazing seal strips are an essential component in the construction and glazing industries, primarily used to provide a weather-tight seal between the glass and the frame of windows and doors. These strips play a crucial role in enhancing energy efficiency, preventing air and water infiltration, and offering structural integrity to glass installations. In this article, we will explore the importance of glazing seal strips, the various types available, and their applications in different settings.

Importance of Glazing Seal Strips

The primary function of glazing seal strips is to create a barrier that prevents water, air, and dust from entering through gaps between the glass and the frame. A well-installed seal strip minimizes the risk of leaks, which can lead to mold growth, damage to the building’s interior, and increased energy costs due to heating and cooling inefficiencies. Furthermore, glazing seal strips contribute to the overall durability of the windows and doors, reducing the likelihood of damage from environmental factors.

Additionally, these strips help in noise reduction by damping sound transmission, enhancing the comfort of indoor spaces. With the growing emphasis on sustainability and energy efficiency, the use of high-quality glazing seal strips has become increasingly important for both new constructions and retrofitting projects.

Types of Glazing Seal Strips

Glazing seal strips come in various materials and profiles, each suited for specific applications. The most common materials include

1. PVC (Polyvinyl Chloride) PVC seal strips are popular for their durability and resistance to moisture, making them suitable for a range of applications, including residential and commercial buildings.

2. EPDM (Ethylene Propylene Diene Monomer) This synthetic rubber material is known for its excellent weather resistance and flexibility. EPDM seal strips are ideal for environments with extreme temperatures, providing a long-lasting seal that can withstand the elements.

3. Silicone Silicone seal strips offer superior flexibility and can withstand a wide temperature range. They are often used in high-performance applications where a robust seal is required.

4. Neoprene Known for its resilience and resistance to aging and weathering, neoprene seal strips are commonly used in areas that experience high exposure to oils and chemicals.

glazing seal strip

5. Foam Foam seal strips are lightweight and easy to install, providing a basic level of insulation. They are typically used for quick repairs or in less critical applications.

Applications of Glazing Seal Strips

Glazing seal strips are versatile and find applications across various sectors

1. Residential Buildings In homes, glazing seal strips are used to weatherproof windows and doors, ensuring energy efficiency and comfort for occupants. Well-sealed windows contribute significantly to reducing heating and cooling expenses.

2. Commercial Buildings In commercial properties, the use of glazing seal strips is critical to maintain comfortable work environments. They help control indoor temperatures and reduce noise pollution, creating a conducive atmosphere for employees and customers alike.

3. Automotive Industry Glazing seal strips are also used in vehicles to secure windows and prevent leaks. They are designed to withstand tough conditions while providing a secure and aesthetic finish.

4. Industrial Settings In factories and warehouses, glazing seal strips are vital for sealing large glass installations to protect equipment and products from environmental damage.

5. Curtain Wall Systems In modern architecture, curtain wall systems often use glazing seal strips to maintain structural integrity while allowing for expansive glass facades.

Conclusion

Glazing seal strips play a fundamental role in ensuring the effectiveness and longevity of glass installations across various sectors. With advancements in materials and technology, the options available cater to a range of performance requirements. By understanding the importance of these seal strips and selecting the appropriate type, builders, architects, and homeowners can significantly enhance the quality and durability of their glass installations. In an era where energy efficiency and environmental considerations are paramount, investing in high-quality glazing seal strips is not just beneficial; it is essential for any serious construction project.

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

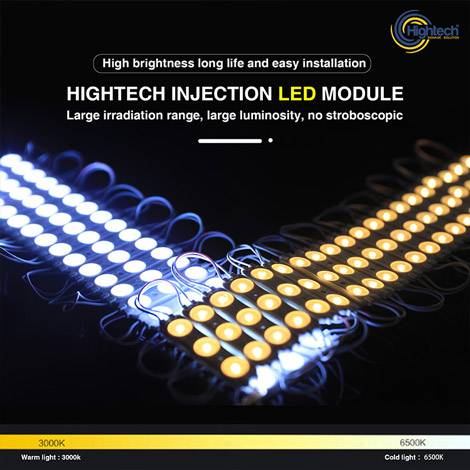

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025

-

Factory Hot Sale Thin Silicone Sewn Strip Roll Wholesale, Durable & Flexible

NewsJul.30,2025