flexible plastic extrusion profile supplier

set. . 18, 2024 21:40 Back to list

flexible plastic extrusion profile supplier

The Versatility of Flexible Plastic Extrusion Profiles

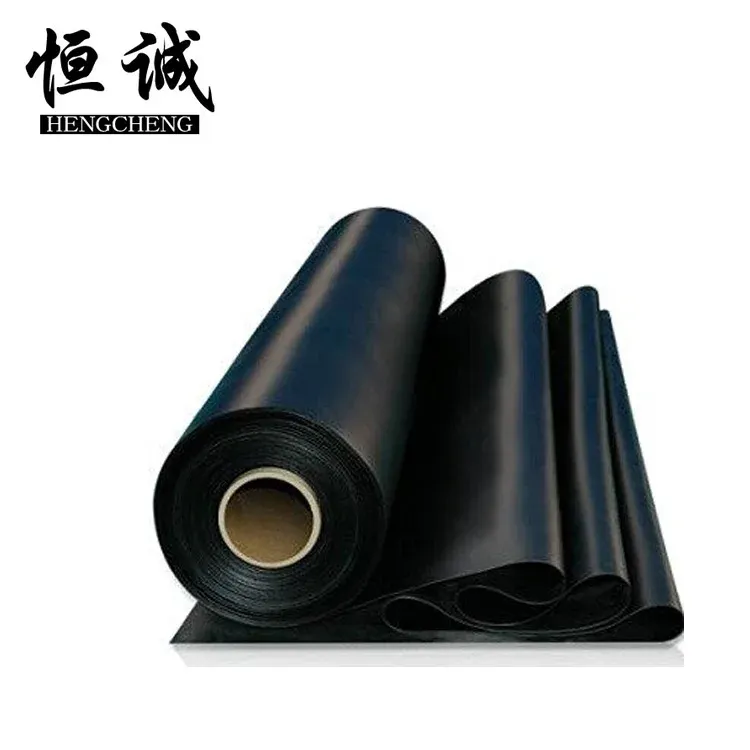

In today's rapidly evolving manufacturing landscape, the demand for innovative and adaptable materials is greater than ever. One such solution that has garnered significant attention is flexible plastic extrusion profiles. These profiles are produced through a process where raw plastic materials are melted and formed into a continuous shape, allowing for a variety of applications across numerous industries.

Flexible plastic extrusion profiles offer a remarkable combination of durability, adaptability, and cost-effectiveness. Their inherent flexibility makes them suitable for applications in industries ranging from automotive to construction, electronics to packaging, and even furniture design. The ability to customize these profiles in terms of shape, size, and color means that businesses can create tailored solutions that meet specific requirements.

Applications Across Multiple Industries

One of the standout features of flexible plastic extrusion profiles is their versatility. In the automotive industry, for example, these profiles are often used for weather stripping, sealing components, and even interior trim. Their resistance to water, chemicals, and temperature fluctuations make them ideal for maintaining the integrity of vehicle components.

In the construction sector, flexible plastic extrusions serve as effective seals for windows and doors, contributing to energy efficiency by reducing air leakage. Additionally, they are used in various architectural applications, including architectural trims and moldings, enhancing the visual appeal while providing functional benefits.

flexible plastic extrusion profile supplier

The electronics industry also benefits significantly from flexible plastic extrusion profiles

. They are commonly used in cable management systems, providing protective coverings for wires and cables, which not only helps in organizing them but also protects them from damage, environmental factors, and electromagnetic interference.The Manufacturing Process

The process of creating flexible plastic extrusion profiles is both efficient and scalable. Manufacturers utilize advanced technology to ensure high-quality outputs tailored to the needs of their clients. The process begins with selecting the appropriate thermoplastic material, such as PVC, TPE, or polyethylene, depending on the desired properties of the final product.

After the material is fed into an extruder, it is heated until it melts, forming a viscous compound. This molten plastic is then forced through a die, which shapes it into the desired profile. Once cooled, the profiles can be cut to specific lengths, packaged, and shipped to customers. The entire process is highly controlled, allowing for consistent quality and performance in every batch.

Conclusion

In conclusion, the role of flexible plastic extrusion profiles in modern manufacturing cannot be overstated. Their adaptability and functionality ensure that they remain a vital resource for various industries. As technology continues to advance and materials science progresses, the potential applications for these profiles are bound to expand further, making them a key player in future designs and innovations. Whether it's enhancing automotive components or improving construction materials, flexible plastic extrusion profiles are fashioned to meet the challenges of a dynamic market. For businesses looking to optimize their operations and product offerings, partnering with a reliable flexible plastic extrusion profile supplier can lead to significant competitive advantages.

-

Durable Plastic-Aluminum Channel Groove Belt Supplier

NewsJun.06,2025

-

Premium Aluminum-Plastic Edge Strip for Signage & Channel Edges

NewsJun.06,2025

-

Thin Silicone Strips for SEG Light Box Frames Durable Supplier & Pricelist

NewsJun.05,2025

-

DuPont Paper Special Adhesive Strip Solutions High-Temp Reliable Factories & Exporters

NewsJun.05,2025

-

Premium U Shape Chrome Trim Strip Supplier OEM & Export Solutions

NewsJun.04,2025

-

Premium White Transparent TPE Tape Durable & Waterproof Solution

NewsJun.04,2025