Automatic sealing strip manufacturing plant.

Jun . 16, 2024 13:44 Back to list

Automatic sealing strip manufacturing plant.

Automatic Lifting Sealing Strip Factory Revolutionizing the Manufacturing Industry

In the heart of the industrial sector, a revolutionary concept is taking shape - the automatic lifting sealing strip factory. This cutting-edge facility represents the pinnacle of modern manufacturing, seamlessly integrating advanced automation technologies to produce high-quality sealing strips with unparalleled efficiency and precision.

The core of this factory's innovation lies in its automated lifting system. This sophisticated mechanism eliminates the need for manual handling of materials, significantly reducing the potential for human error and increasing production speeds. Raw materials are fed into the system, where they are automatically lifted, transported, and positioned at various stages of the production process. This not only optimizes workflow but also enhances worker safety by minimizing physical strain and hazardous interactions with heavy machinery.

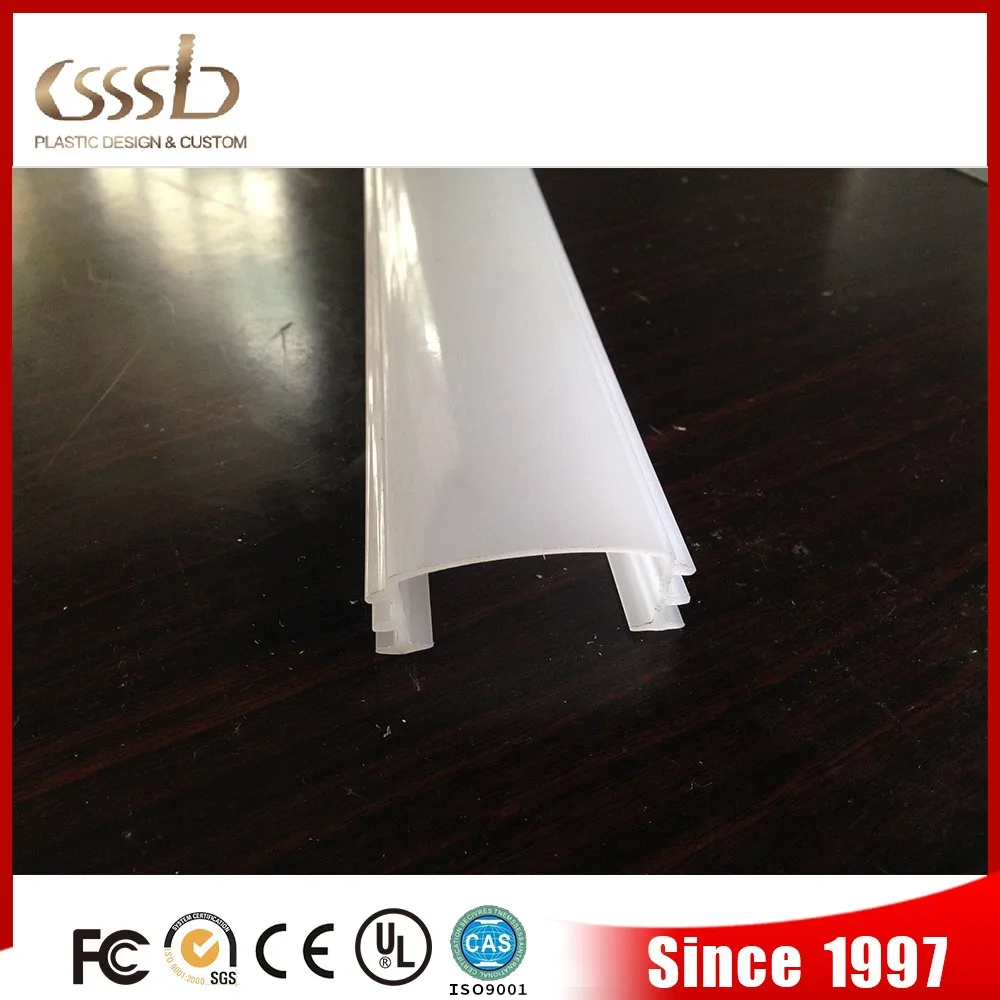

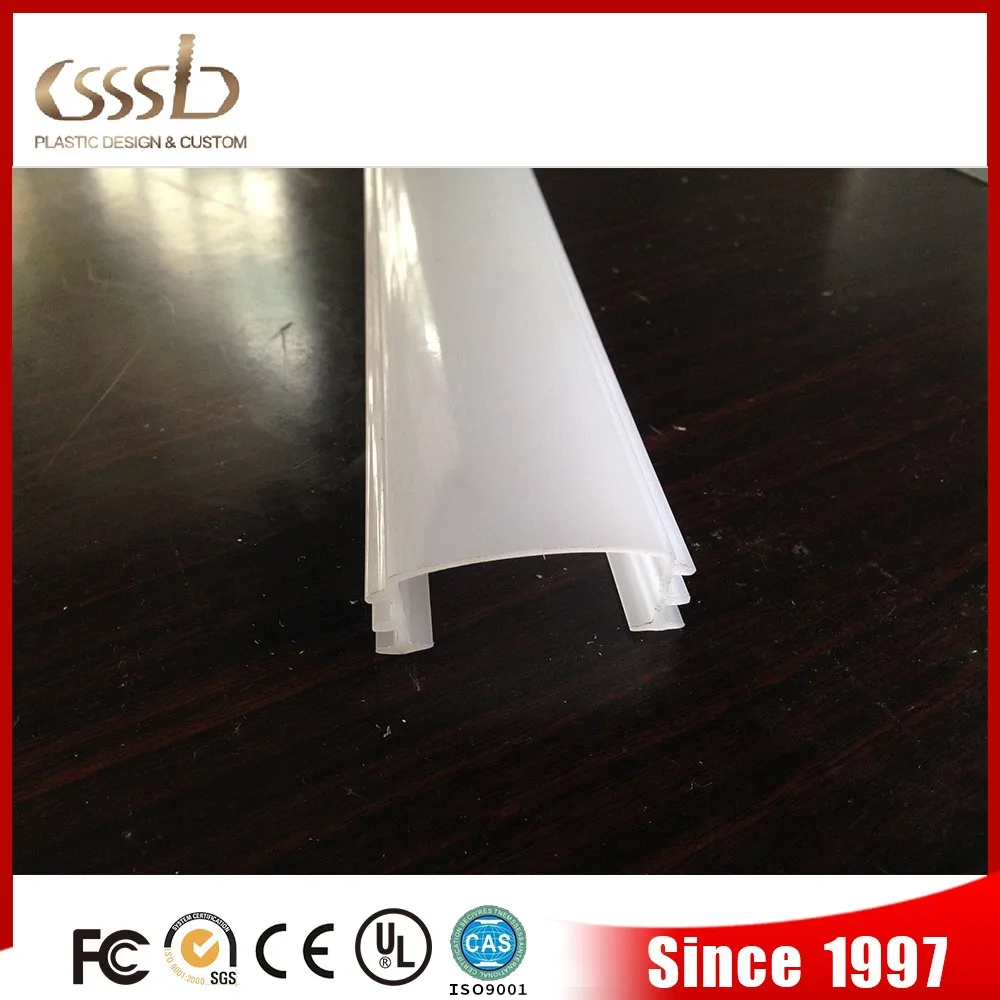

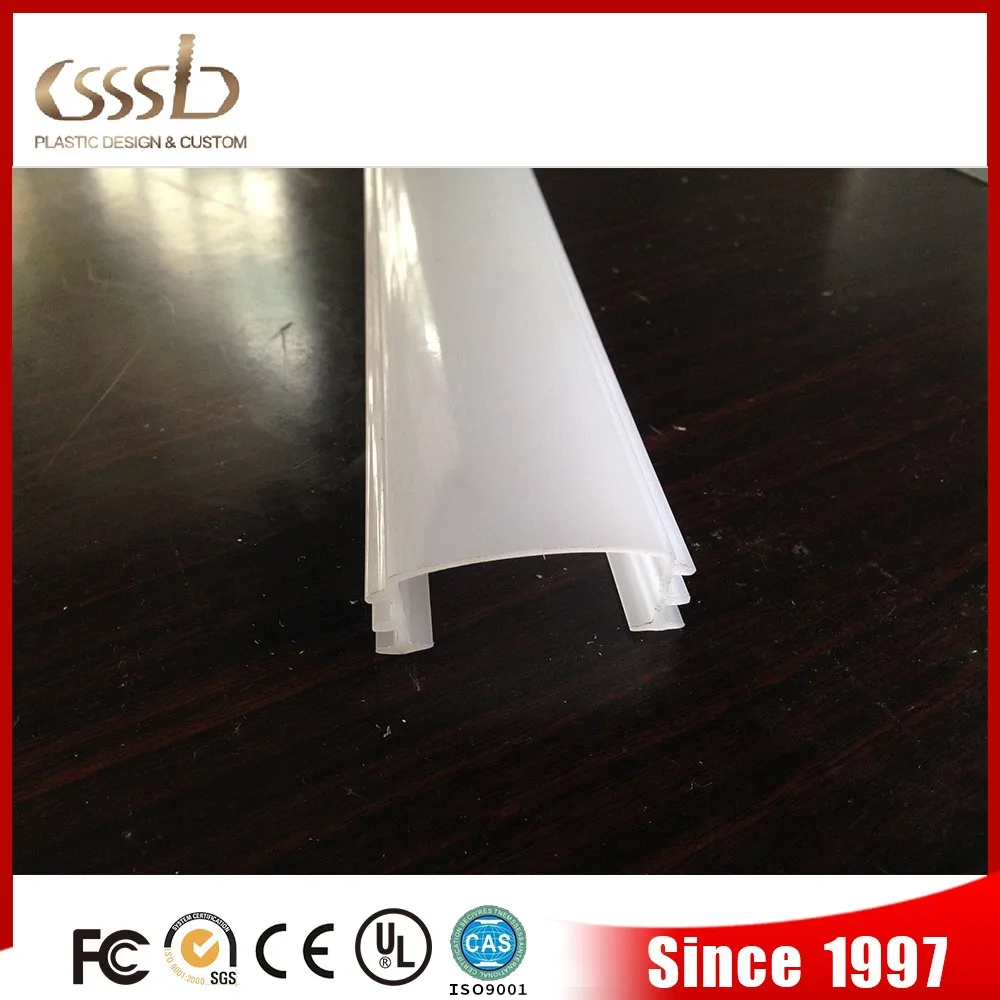

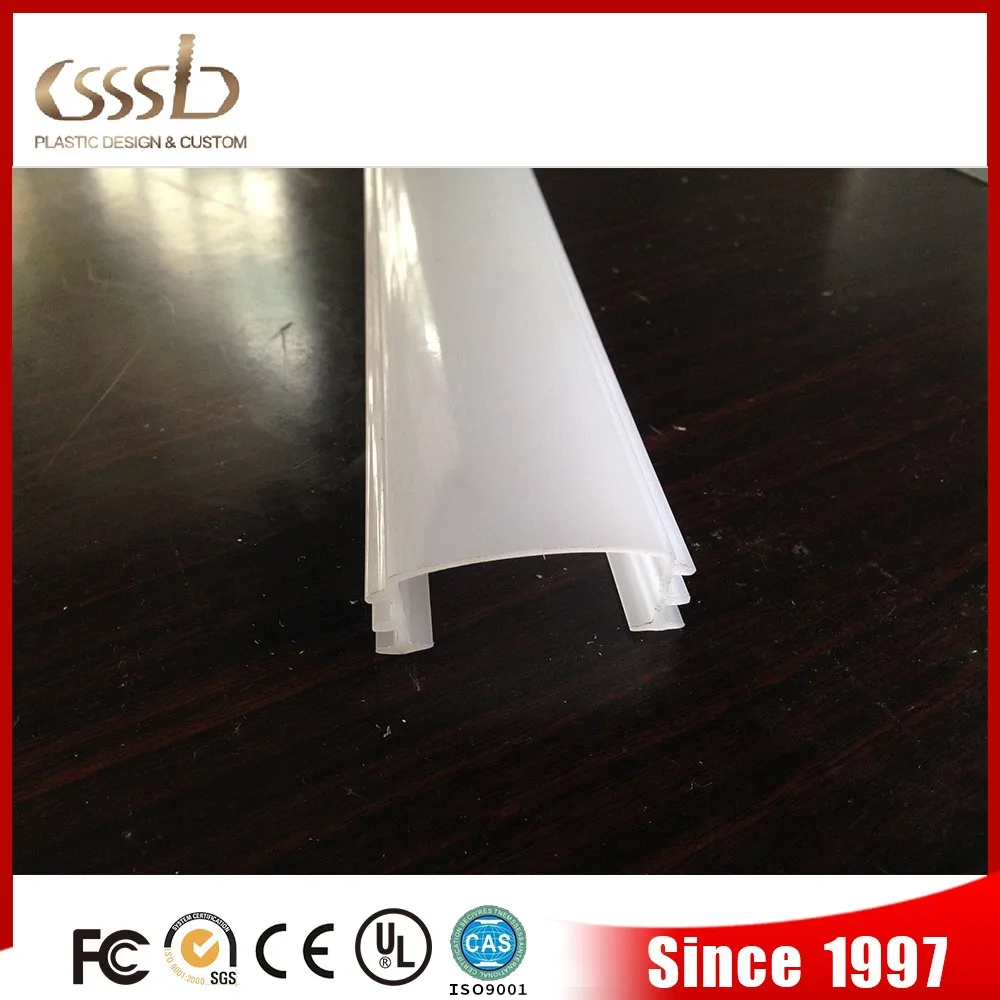

The sealing strips produced in this factory serve a critical function in numerous industries. They ensure airtight and watertight seals in doors and windows across residential, commercial, and industrial settings. These strips are crafted from durable materials that can withstand extreme temperatures, weather conditions, and physical stress, making them indispensable components in construction and automotive sectors.

Quality control is paramount in this high-tech environment. Advanced sensors and monitoring systems are integrated throughout the production line, ensuring that each sealing strip meets stringent quality standards. From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output

From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output automatic lifting sealing strip factory.

The environmental impact of this factory is also a key consideration. By optimizing resource use and reducing waste through precise automation, the facility operates with a minimal carbon footprint. Energy-efficient machines and processes further reinforce its commitment to sustainability.

Looking ahead, the automatic lifting sealing strip factory is poised to transform the sealing industry. Its adoption of automated technologies not only boosts productivity and quality but also paves the way for future advancements. As we continue to embrace the Fourth Industrial Revolution, this factory stands as a beacon of what can be achieved when human ingenuity and cutting-edge technology converge.

In summary, the automatic lifting sealing strip factory is a testament to the power of automation in manufacturing. Its ability to produce superior sealing strips efficiently and sustainably signifies a major leap forward for industries reliant on these vital components. As we look to the future, this factory serves as a blueprint for how technology can reshape the very foundations of production and industrial growth.

automatic lifting sealing strip factory.

The environmental impact of this factory is also a key consideration. By optimizing resource use and reducing waste through precise automation, the facility operates with a minimal carbon footprint. Energy-efficient machines and processes further reinforce its commitment to sustainability.

Looking ahead, the automatic lifting sealing strip factory is poised to transform the sealing industry. Its adoption of automated technologies not only boosts productivity and quality but also paves the way for future advancements. As we continue to embrace the Fourth Industrial Revolution, this factory stands as a beacon of what can be achieved when human ingenuity and cutting-edge technology converge.

In summary, the automatic lifting sealing strip factory is a testament to the power of automation in manufacturing. Its ability to produce superior sealing strips efficiently and sustainably signifies a major leap forward for industries reliant on these vital components. As we look to the future, this factory serves as a blueprint for how technology can reshape the very foundations of production and industrial growth.

From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output

From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output From the consistency of the material to the dimensions of the final product, every detail is scrutinized to guarantee a flawless output automatic lifting sealing strip factory.

The environmental impact of this factory is also a key consideration. By optimizing resource use and reducing waste through precise automation, the facility operates with a minimal carbon footprint. Energy-efficient machines and processes further reinforce its commitment to sustainability.

Looking ahead, the automatic lifting sealing strip factory is poised to transform the sealing industry. Its adoption of automated technologies not only boosts productivity and quality but also paves the way for future advancements. As we continue to embrace the Fourth Industrial Revolution, this factory stands as a beacon of what can be achieved when human ingenuity and cutting-edge technology converge.

In summary, the automatic lifting sealing strip factory is a testament to the power of automation in manufacturing. Its ability to produce superior sealing strips efficiently and sustainably signifies a major leap forward for industries reliant on these vital components. As we look to the future, this factory serves as a blueprint for how technology can reshape the very foundations of production and industrial growth.

automatic lifting sealing strip factory.

The environmental impact of this factory is also a key consideration. By optimizing resource use and reducing waste through precise automation, the facility operates with a minimal carbon footprint. Energy-efficient machines and processes further reinforce its commitment to sustainability.

Looking ahead, the automatic lifting sealing strip factory is poised to transform the sealing industry. Its adoption of automated technologies not only boosts productivity and quality but also paves the way for future advancements. As we continue to embrace the Fourth Industrial Revolution, this factory stands as a beacon of what can be achieved when human ingenuity and cutting-edge technology converge.

In summary, the automatic lifting sealing strip factory is a testament to the power of automation in manufacturing. Its ability to produce superior sealing strips efficiently and sustainably signifies a major leap forward for industries reliant on these vital components. As we look to the future, this factory serves as a blueprint for how technology can reshape the very foundations of production and industrial growth. Latest news

-

Plastic + Aluminum Channel Aluminum Groove Belt Supplier - Premium Channel Edge Products Exporter

NewsJun.10,2025

-

High Quality Chrome Trim Strip Leading Manufacturer & Custom Factories Service

NewsJun.10,2025

-

Premium Car Trim Strip – Leading Car Moulding Trim Strip Exporters & 3 Car Moldings Trim Strip Manufacturers

NewsJun.10,2025

-

Premium White Transparent PVC Adhesive Strips Strong Bond & Waterproof

NewsJun.10,2025

-

Premium Plastic Aluminum Channel Groove Belt for Durability

NewsJun.10,2025

-

Aluminum Rubber Edge Channel Groove Sideband Durable Edge Protector

NewsJun.10,2025