CE Certification for Color Coated Products and Their Quality Standards

Νοέ . 07, 2024 15:32 Back to list

CE Certification for Color Coated Products and Their Quality Standards

Understanding CE Certification and Color Coated Products

In today's globalized marketplace, the safety and quality of products are pivotal, particularly in sectors like construction, manufacturing, and consumer goods. One important standard that ensures products meet specific safety and environmental criteria is CE certification. This article delves into CE certification, particularly in relation to color-coated products, exploring its significance, processes, and implications for manufacturers and consumers.

What is CE Certification?

CE stands for “Conformité Européenne,” which translates to “European Conformity.” It is a mandatory mark for products sold within the European Economic Area (EEA) and indicates that a product complies with EU legislation regarding health, safety, and environmental protection. Products bearing the CE mark can move freely throughout the European market, which is essential for manufacturers looking to expand their reach.

The CE certification process involves rigorous testing and evaluation based on the specific directives applicable to the product category. For example, construction materials and consumer goods must adhere to different sets of regulations. The certification not only helps in ensuring quality compliance but also protects consumers and enhances product credibility.

The Role of Color Coated Products

Color-coated products have gained immense popularity in various applications, particularly in the construction industry, where they are used for roofing, wall panels, and interior applications. These products are typically created by applying a layer of paint or pigment to a substrate, such as metal or plastic. The benefits of color-coated products include aesthetic appeal, extra protection against corrosion, and improved durability.

In the context of CE certification, manufacturers of color-coated products need to ensure that their items meet relevant EU standards. This includes compliance with directives related to construction products (CPR), environmental performance, and safety regulations.

Importance of CE Certification for Color Coated Products

1. Market Access CE certification is crucial for manufacturers looking to sell color-coated products in Europe. Without the CE mark, these products cannot be legally sold in the EU market, which limits potential sales and revenue.

2. Quality Assurance The certification process involves rigorous testing to ensure that products are safe and perform as advertised. For color-coated products, this means demonstrating that they can withstand various environmental conditions while maintaining their aesthetic quality.

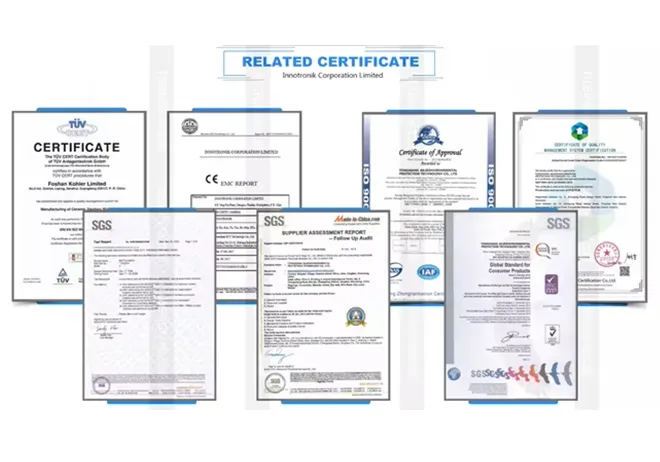

ce cetification color coated

3. Consumer Trust Consumers are more likely to purchase products that are CE certified. The mark signifies that a product has been evaluated and meets stringent EU standards, boosting consumer confidence.

4. Regulatory Compliance Many countries outside the EU also recognize CE certification as a benchmark for quality and safety. Therefore, obtaining CE certification can provide manufacturers with an advantage in international markets.

The Certification Process

To achieve CE certification for color-coated products, manufacturers must follow a systematic process

1. Identify Applicable EU Directives The first step involves determining which EU directives apply to the product in question.

2. Conduct Testing The next step is to perform the necessary tests to ensure compliance with relevant standards. This often involves third-party laboratories that are accredited to evaluate product safety and performance.

3. Compile Technical Documentation Manufacturers must prepare a technical file that includes details about the product, the testing conducted, and evidence of compliance.

4. Declaration of Conformity After successful testing, manufacturers must draft and sign a Declaration of Conformity, which states that the product meets all pertinent EU regulations.

5. Affix the CE Mark Finally, once all requirements have been met, the CE mark can be affixed to the product.

Conclusion

In conclusion, CE certification is vital for manufacturers of color-coated products seeking to penetrate the European market. It not only facilitates market access but also ensures the safety and quality of products, thereby enhancing consumer trust and business credibility. Understanding the certification process and its implications can help manufacturers effectively navigate regulatory landscapes, ultimately leading to success in an increasingly competitive environment. As global standards evolve, staying compliant will be crucial for long-term sustainability and growth.

-

Factory Hot Sale Recycled Green Elastic Profiles Wholesale Supplier

NewsJul.25,2025

-

Hi flo Oil Filter H F155 for KT M 250 EXC Racing 2003-2006, OEM Quality

NewsJul.24,2025

-

Top LED Neon Rope Light Outdoor Companies – Durable & Weatherproof Solutions

NewsJul.23,2025

-

Top Window Seal Strip Adhesive Companies for Quality Sealing Solutions

NewsJul.22,2025

-

HighTech Injection LED Module Size 6414 - Efficient, Durable Lighting

NewsJul.22,2025

-

Top Window Seal Strip Adhesive Companies | Durable Weatherproof Seals

NewsJul.21,2025