Rubber Door Strip Seal Manufacturers and Their Key Innovations in Sealing Solutions

aŭg . 16, 2024 16:36 Back to list

Rubber Door Strip Seal Manufacturers and Their Key Innovations in Sealing Solutions

The Importance of Rubber Door Strip Seals in Modern Manufacturing

In the fast-paced world of manufacturing and construction, every detail counts in the quest for efficiency and effectiveness. One often overlooked but critical component that contributes to these goals is the rubber door strip seal. This humble product plays a significant role in enhancing thermal efficiency, reducing noise, and preventing dust and moisture intrusion. As industries evolve, the demand for high-quality rubber door strip seals is increasing, leading to the establishment and growth of specialized factories focused on producing these essential components.

Understanding Rubber Door Strip Seals

Rubber door strip seals are designed to be installed along the edges of doors and windows. They serve multiple functions, including sealing gaps that can lead to energy loss and creating a more comfortable indoor environment. By providing a tight seal, these strips help maintain the desired temperature within buildings, thereby reducing the workload on heating and cooling systems. This reduction can result in significant energy savings for both residential and commercial spaces.

The Manufacturing Process

The production of rubber door strip seals involves sophisticated processes that require precision and quality control. Factories specializing in these seals employ advanced techniques that include extrusion and molding, where raw rubber is transformed into the desired shapes and sizes. Manufacturers often use a combination of natural and synthetic rubber to create products that are durable and resilient, capable of withstanding various environmental conditions.

Quality control is paramount in the production of rubber seals. Many factories implement rigorous testing procedures to ensure that their products meet industry standards. These tests evaluate the seals for durability, flexibility, and resistance to factors such as UV radiation and extreme temperatures. By adhering to high standards, manufacturers can assure clients of the reliability and longevity of their seals.

Applications of Rubber Door Strip Seals

rubber door strip seal factories

The applications of rubber door strip seals extend across various industries. In the construction sector, builders regularly use these seals to improve energy efficiency in residential and commercial buildings. In the automotive industry, rubber seals are employed in vehicles to prevent water ingress and noise pollution, contributing to a more pleasant driving experience.

Moreover, food and pharmaceutical industries utilize rubber door strips to maintain clean environments. Seals help prevent the entry of unwanted contaminants, ensuring compliance with health and safety regulations. Additionally, in industries involving temperature-sensitive products, like logistics and warehousing, proper sealing is crucial to uphold quality and safety standards.

The Future of Rubber Door Strip Seal Factories

As sustainability becomes a core focus for manufacturers globally, rubber door strip seal factories are also adapting. There is a growing trend toward using recycled materials and developing eco-friendly rubber compounds. This shift not only satisfies environmental regulations but also appeals to a consumer market increasingly concerned about sustainability.

Innovations in manufacturing technology, such as 3D printing and automation, will further enhance the efficiency of factories producing rubber door strip seals. These advancements will lower production costs, reduce waste, and allow for customizable solutions to meet specific client needs.

Conclusion

Rubber door strip seal factories play a vital role in numerous industries by providing essential components that enhance building performance, protect sensitive environments, and ultimately lead to greater energy efficiency. As technology and sustainability practices continue to evolve, these factories will be at the forefront of innovation, ensuring that rubber door strip seals remain a critical component in modern manufacturing and construction. The significance of this simple yet effective product cannot be overstated, as it contributes to the comfort and efficiency of our built environment.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

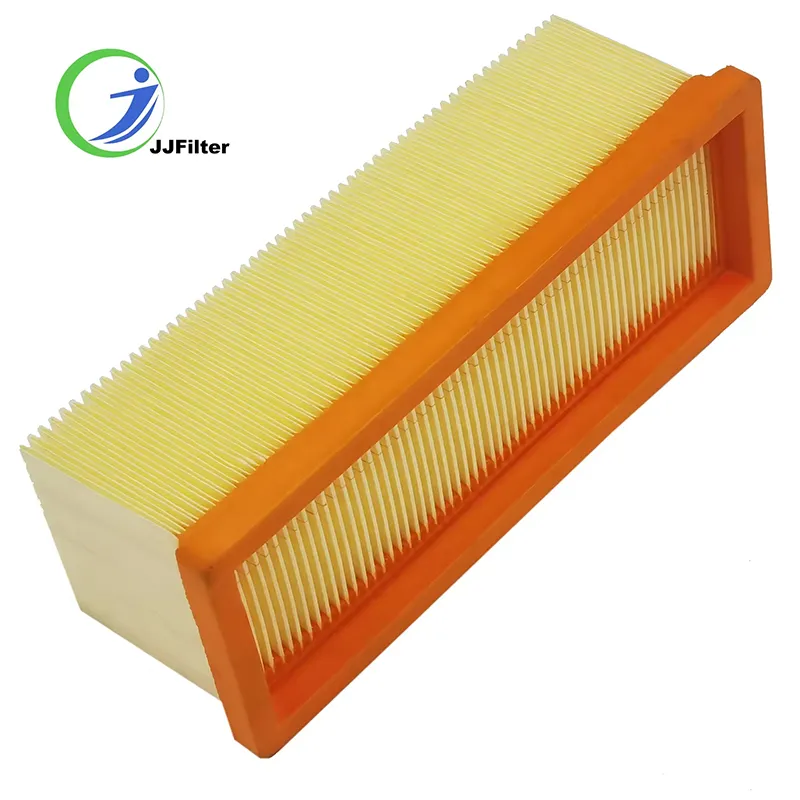

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025