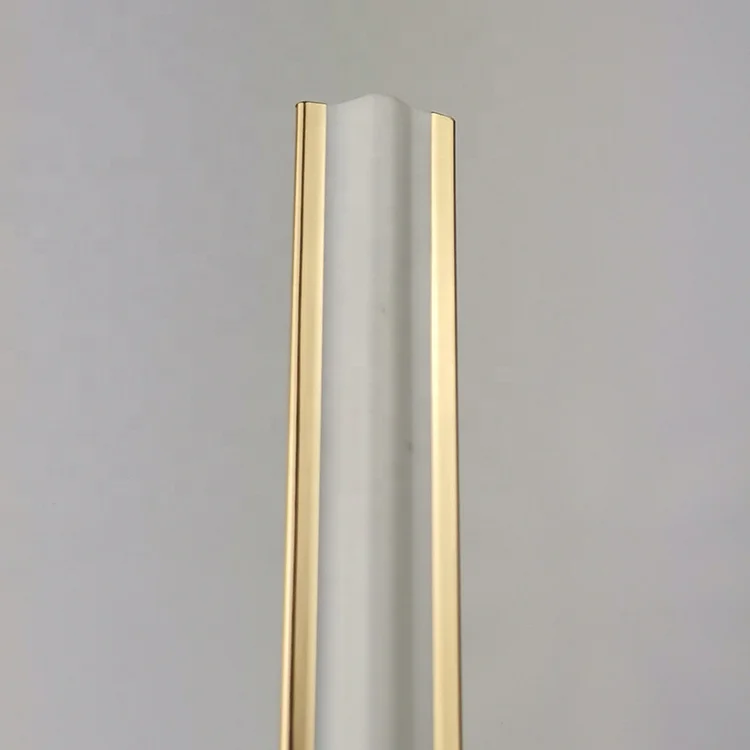

3m adhesive backed silicone

jaan. . 19, 2025 05:02 Back to list

3m adhesive backed silicone

Enhancing your projects with the use of 3M adhesive backed silicone isn't just a trend; it’s a revolution in how we understand material performance. The utility and versatility of this component make it a staple choice among industry experts, from aerospace to consumer electronics. Here’s why integrating 3M adhesive backed silicone into your projects might be not only essential but transformative.

But application experience goes beyond the material itself; it's also about the ease of use. Installation of 3M adhesive backed silicone is straightforward, even for those with less advanced technical skills. Unlike other overly complex adhesive systems requiring numerous steps and tools, 3M's product is about simplifying application while ensuring maximum adherence and reliability. Furthermore, 3M takes an authoritative leap in the material science industry by ensuring all their adhesive backed silicones are manufactured with sustainability in mind. As environmental impact becomes crucial in industrial production decisions, 3M provides solutions that not only meet but exceed ecological standards. This reflects an informed choice for professionals who not only seek quality but are also committed to sustainable development. The breadth of availability of 3M adhesive backed silicone also speaks volumes about its trustworthiness. Available across a wide range of industries, including automotive, construction, and healthcare, it is the reliability and versatility of this product that have cemented its authority and preference among professionals worldwide. Testimonials from reputable sources and leading industry professionals attest to the silicone’s role in enhancing product performance and extending lifecycle, contributing to its standing as a go-to solution. In summary, opting for 3M adhesive backed silicone isn’t just choosing a product; it’s embracing a comprehensive, well-researched, and expertly crafted solution. Experts endorse it, the industry trusts it, and experience validates it. As innovation continues to drive forward industrial capabilities, integrating this material into your projects not only aligns with modern engineering standards but sets the stage for enhanced performance and sustained success in your applications.

But application experience goes beyond the material itself; it's also about the ease of use. Installation of 3M adhesive backed silicone is straightforward, even for those with less advanced technical skills. Unlike other overly complex adhesive systems requiring numerous steps and tools, 3M's product is about simplifying application while ensuring maximum adherence and reliability. Furthermore, 3M takes an authoritative leap in the material science industry by ensuring all their adhesive backed silicones are manufactured with sustainability in mind. As environmental impact becomes crucial in industrial production decisions, 3M provides solutions that not only meet but exceed ecological standards. This reflects an informed choice for professionals who not only seek quality but are also committed to sustainable development. The breadth of availability of 3M adhesive backed silicone also speaks volumes about its trustworthiness. Available across a wide range of industries, including automotive, construction, and healthcare, it is the reliability and versatility of this product that have cemented its authority and preference among professionals worldwide. Testimonials from reputable sources and leading industry professionals attest to the silicone’s role in enhancing product performance and extending lifecycle, contributing to its standing as a go-to solution. In summary, opting for 3M adhesive backed silicone isn’t just choosing a product; it’s embracing a comprehensive, well-researched, and expertly crafted solution. Experts endorse it, the industry trusts it, and experience validates it. As innovation continues to drive forward industrial capabilities, integrating this material into your projects not only aligns with modern engineering standards but sets the stage for enhanced performance and sustained success in your applications.

Latest news

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025

-

Top Window Seal Strip Adhesive Companies - Durable & Reliable

NewsAug.18,2025