Innovative Approaches in Single Edge Aluminum Factory Production Techniques and Efficiency

دسامبر . 17, 2024 15:47 Back to list

Innovative Approaches in Single Edge Aluminum Factory Production Techniques and Efficiency

The Emergence and Significance of Single Edge Aluminum Factories

In recent years, the aluminum industry has witnessed a transformation marked by technological advancements and a growing emphasis on sustainable production. Among the innovative facilities that have arisen in this sector, single edge aluminum factories stand out as a noteworthy development. These factories are designed to focus on the production of aluminum with optimized processes that enhance efficiency, reduce waste, and meet the ever-increasing demand for high-quality aluminum products.

Understanding Single Edge Aluminum Factories

Single edge aluminum factories are specialized manufacturing plants that utilize cutting-edge methods to produce aluminum sheets, extrusions, and other forms. The term single edge refers primarily to the streamlined processes these factories implement, allowing for the efficient handling of materials and minimal downtime during production. Unlike traditional factories that may have multiple lines or processes intertwined, single edge aluminum factories focus on optimizing a single production pathway, which significantly boosts productivity.

One of the key features of these factories is their incorporation of advanced automation technologies. Robotics and automated systems are extensively used to handle material movement, cutting, and quality inspections, which not only enhance speed but also improve consistency and precision in production. This automation also plays a vital role in reducing labor costs and safety risks for workers, as machines take over hazardous tasks.

Environmental Considerations

Sustainability has become a critical consideration in manufacturing, especially in industries such as aluminum production that have historically faced scrutiny for their environmental impact. Single edge aluminum factories are designed with sustainability in mind, employing practices that minimize energy consumption and waste generation.

For instance, these factories often utilize energy-efficient machinery that conforms to the latest environmental standards. They may also incorporate recycling systems that allow for the recovery and reuse of aluminum scrap produced during the manufacturing process. This closed-loop system not only reduces the need for virgin materials but also significantly lessens the carbon footprint of aluminum production.

single edge aluminum factories

Furthermore, the use of renewable energy sources, such as solar or wind power, is becoming increasingly common in single edge aluminum factories

. By harnessing clean energy, these facilities can lower their reliance on fossil fuels and contribute to the global effort to combat climate change.Meeting Market Demands

The demand for aluminum products has surged over the past decade, driven by various sectors such as automotive, aerospace, construction, and consumer goods. Aluminum's lightweight, corrosion-resistant properties make it an ideal material for these applications. Single edge aluminum factories are adept at responding to these market demands by offering customizable solutions that meet the specific needs of their clients.

These factories enable rapid prototyping and short production runs, allowing manufacturers to quickly adapt to changing market conditions or consumer preferences. Additionally, the ability to produce high-quality aluminum products efficiently ensures that companies can maintain a competitive edge in their respective industries.

Challenges and Future Prospects

Despite the numerous advantages of single edge aluminum factories, they are not without challenges. The initial investment in advanced technology and machinery can be significant, which may deter smaller manufacturers from adopting this model. Furthermore, the industry faces ongoing pressure to innovate continuously while remaining cost-effective.

However, the future of single edge aluminum factories looks promising. As technology continues to evolve, more cost-effective solutions are likely to emerge, making these factories accessible to a broader range of businesses. Additionally, as global demand for aluminum continues to rise, the need for efficient, sustainable production facilities will only deepen.

In conclusion, single edge aluminum factories represent a pivotal evolution in the aluminum manufacturing industry. Through their focus on efficiency, sustainability, and adaptability, they are not only meeting today's market demands but also paving the way for future innovations. As they continue to develop, these factories will play an increasingly integral role in shaping the landscape of aluminum production, aligning with the goals of both manufacturers and consumers in the quest for a greener, more efficient future.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

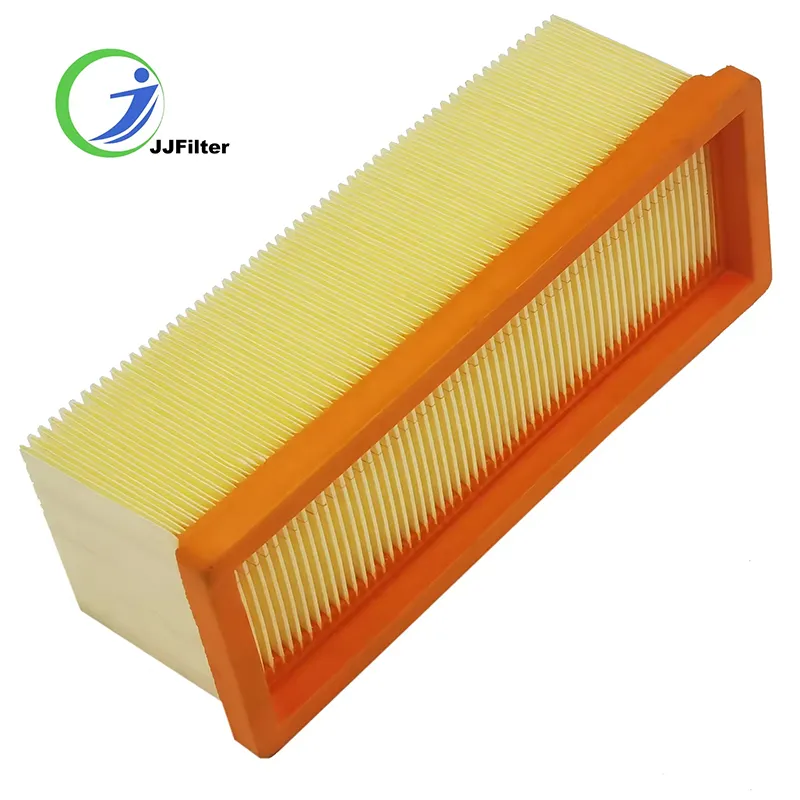

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025