Sponge Rubber Seal Strip: A Customizable Seal Solution Built for Flexibility and Performance

May . 13, 2025 11:10 Ar ais chuig an liosta

Sponge Rubber Seal Strip: A Customizable Seal Solution Built for Flexibility and Performance

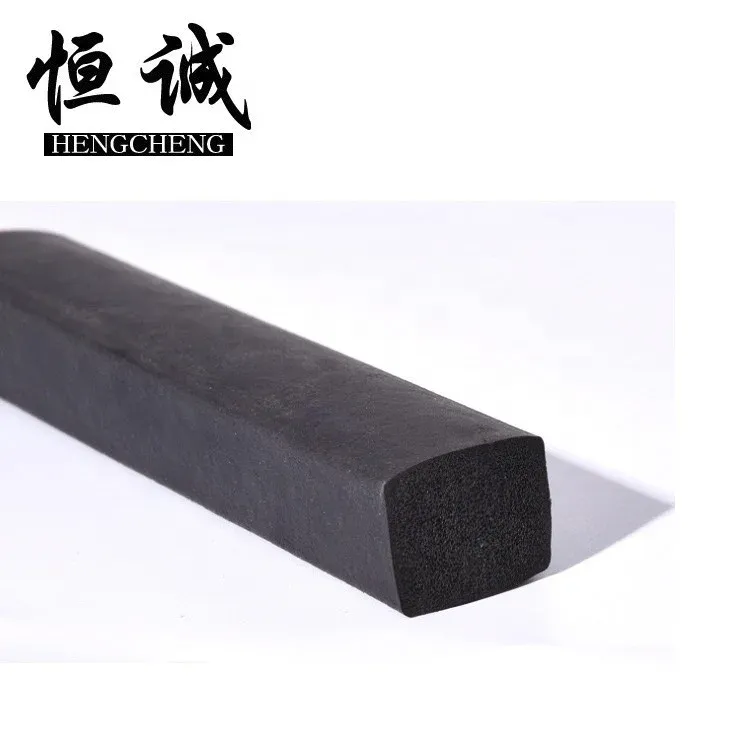

In the ever-evolving world of sealing technology, flexibility, performance, and visual integration are critical factors. That’s where the sponge rubber seal strip stands out—not only does it provide exceptional sealing against air, water, and dust, but it also supports a wide range of customization options, making it the first choice for manufacturers across various industries. From residential window frames to industrial machinery, the sponge rubber seal strip has become a preferred solution due to its soft structure, compressibility, and adaptability.

How the Sponge Rubber Seal Strip is Manufactured

The production of the sponge rubber seal strip involves precision, consistency, and carefully controlled chemical processes. Typically made from materials such as EPDM, neoprene, or silicone, the base rubber compound is mixed with a blowing agent that creates the sponge-like texture during vulcanization.

The process begins with raw rubber mixing, where specific polymers are combined with additives for UV resistance, fire retardancy, or thermal insulation. A blowing agent is then incorporated, which releases gas under heat, causing the rubber to expand and form a porous structure. The extrusion phase shapes the sponge rubber seal strip into the required profile—whether D, E, P, or custom—before it's vulcanized in a heated oven to set its spongy texture permanently.

Quality assurance is a key part of the manufacturing workflow. Each Séala spúinse is checked for uniform cell structure, dimensional accuracy, and surface finish. This ensures not just durability but reliable long-term sealing performance across applications.

Sponge Rubber Seal Strip:Color Customization and Its Advantages in Design Integration

One of the most appealing and overlooked advantages of the sponge rubber seal strip is its ability to be customized by color. While black remains the most commonly used due to its UV resistance and dirt-hiding properties, manufacturers can produce sponge rubber seal strip options in gray, white, red, blue, or even translucent finishes, depending on customer needs.

This versatility allows businesses to align their sealing materials with their product aesthetics. For example, a shower rubber seal strip in clear or frosted finish blends seamlessly with modern glass bathroom designs. In window systems, a gray or white window seal rubber strip can match light-toned frames for a cleaner appearance.

Color customization isn’t just about looks—it also improves product identification and safety. Using color-coded sponge rubber seal strip profiles in industrial settings helps distinguish seal types for maintenance teams, enhancing workflow efficiency.

Sponge Rubber Seal Strip:Closed Cell vs. Open Cell Sponge Structures

Understanding the internal structure of a sponge rubber seal strip is crucial for choosing the right solution for your project. The two primary types of sponge rubber structures—closed cell and open cell—offer different sealing properties and compression behavior.

A closed cell Sponge seal features air pockets that are completely enclosed. This makes it resistant to water absorption, which is perfect for environments exposed to moisture or outdoor use. It offers superior insulation against water, air, and sound. Applications like a shower rubber seal strip or exterior window seal rubber strip greatly benefit from this configuration.

In contrast, an open cell Séala spúinse has interconnected pores, making it more breathable but less water-resistant. These are often used where air flow or sound absorption is more critical than water sealing. The open cell structure is softer and compresses more easily, making it ideal for indoor use, electronics, or acoustic barriers.

Choosing the right cell type enhances not only the performance but also the lifespan of the sponge rubber seal strip in specific environments.

Sponge Rubber Seal Strip:Applications and Benefits Across Various Industries

The sponge rubber seal strip is highly valued across sectors because of its exceptional compressibility, flexibility, and ease of installation. In the automotive industry, it’s used for sealing doors, trunks, and hoods, where vibration damping and weatherproofing are crucial. For residential construction, the window seal rubber strip offers excellent insulation, reducing energy consumption by preventing drafts and leaks.

Bathroom fittings benefit greatly from a shower rubber seal strip, as it provides both sealing and cushioning for glass doors, resisting mold and mildew thanks to its closed-cell structure. In HVAC and electrical enclosures, Séala spúinse materials act as dust and moisture barriers while reducing noise and vibration.

Additionally, the soft nature of the sponge rubber seal strip makes it safe for sensitive applications like laboratory equipment, consumer appliances, and even medical instruments where non-marking and non-toxic materials are essential.

The lightweight structure makes transportation and handling easier, while its natural elasticity simplifies installation without adhesives or tools. Once in place, it remains effective for years, withstanding temperature changes, UV exposure, and mechanical stress.

Sponge Rubber Seal Strip FAQs

What is the main advantage of using a sponge rubber seal strip over solid rubber?

The sponge rubber seal strip offers better compressibility, making it ideal for creating seals in uneven or low-force applications. It adapts more easily to contours while maintaining an effective seal.

Can I request a specific color for my sponge rubber seal strip?

Yes! Custom color options are available for the sponge rubber seal strip. This is especially useful for matching the seal with the color of your frames or equipment for a seamless look.

What’s the difference between closed and open cell sponge seal structures?

A closed cell Sponge seal repels water and air, making it great for outdoor or wet areas like shower rubber seal strip applications. Open cell structures absorb air and are better for cushioning or sound dampening.

Is a sponge rubber seal strip suitable for window applications?

Absolutely. The window seal rubber strip made from sponge rubber ensures a tight fit, offers weather resistance, and helps reduce noise and energy loss in both commercial and residential settings.

How long does a sponge rubber seal strip typically last?

A high-quality sponge rubber seal strip can last many years depending on the environment. When properly installed and maintained, it resists UV damage, ozone, and temperature extremes.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NuachtNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NuachtNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NuachtNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NuachtNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NuachtNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NuachtNov.22,2025