rubber strip flat strip rectangular

Faoi . 20, 2025 05:51 Back to list

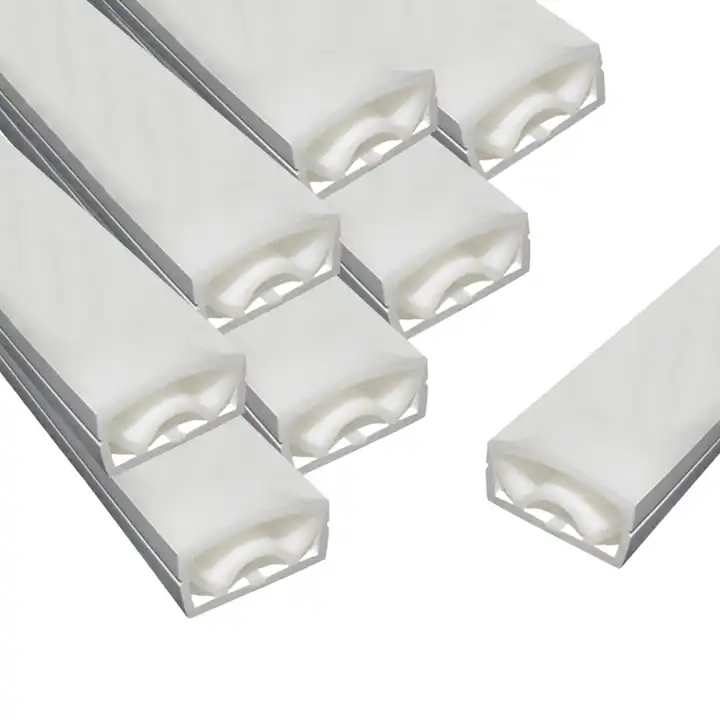

rubber strip flat strip rectangular

Rubber strips, especially those in flat and rectangular forms, play a crucial yet often overlooked role in various industries. These essential components can be found in everything from automotive parts to home appliances, serving as seals, insulators, or even just as protective layers. Understanding their applications, benefits, and the science behind their construction can significantly enhance how industries utilize these versatile materials.

Industry leaders recognize the authority that comes from having a legacy of experience and knowledge in manufacturing rubber materials. Reputable companies invest significantly in research and development to innovate and adapt their products to the ever-changing demands of industries they serve. Such companies are often accredited by international quality standards organizations, ensuring their products meet global safety regulations and perform reliably under specified conditions. Trust is a fundamental aspect when selecting rubber strip suppliers. Customers need assurance that the materials they purchase will consistently meet expected performance criteria. This trust is built through transparent business practices, verified product testing, and customer reviews that attest to the long-term reliability of the supplier's rubber strips. Certifications from reputable industry bodies further reinforce credibility, ensuring the specifications of rubber strips such as tensile strength, elongation, and compression set align with industry benchmarks. In conclusion, flat and rectangular rubber strips are indispensable components across diverse applications due to their adaptability and the functional benefits they offer. Leveraging expertise in production, maintaining authoritativeness through innovation and certifications, and cultivating trust through reliable product performance are vital to selecting and using rubber materials effectively. Businesses striving for operational efficiency and productivity can gain significant advantages through informed choices and informed collaboration with reputable suppliers in the rubber industry.

Industry leaders recognize the authority that comes from having a legacy of experience and knowledge in manufacturing rubber materials. Reputable companies invest significantly in research and development to innovate and adapt their products to the ever-changing demands of industries they serve. Such companies are often accredited by international quality standards organizations, ensuring their products meet global safety regulations and perform reliably under specified conditions. Trust is a fundamental aspect when selecting rubber strip suppliers. Customers need assurance that the materials they purchase will consistently meet expected performance criteria. This trust is built through transparent business practices, verified product testing, and customer reviews that attest to the long-term reliability of the supplier's rubber strips. Certifications from reputable industry bodies further reinforce credibility, ensuring the specifications of rubber strips such as tensile strength, elongation, and compression set align with industry benchmarks. In conclusion, flat and rectangular rubber strips are indispensable components across diverse applications due to their adaptability and the functional benefits they offer. Leveraging expertise in production, maintaining authoritativeness through innovation and certifications, and cultivating trust through reliable product performance are vital to selecting and using rubber materials effectively. Businesses striving for operational efficiency and productivity can gain significant advantages through informed choices and informed collaboration with reputable suppliers in the rubber industry.

Next:

Latest news

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025

-

Top Window Seal Strip Adhesive Companies - Durable & Reliable

NewsAug.18,2025