U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

Iuch . 07, 2025 08:47 Back to list

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

- Introduction to u shape chrome trim strip

s: Overview and significance - Key data insights: Market growth, production trends, and export statistics

- Technical advantages of advanced chrome trim strip manufacturing

- Comparing leading factories, exporters, and product range with a data table

- Tailored solutions: Innovative customization for unique project requirements

- Global applications and industry case studies

- Conclusion: The expanding market of u shape chrome trim strips and future prospects

(u shape chrome trim strip)

Introduction: The Global Emergence of u shape chrome trim strip

In today's automotive and interior design sectors, u shape chrome trim strip has become a defining element for both aesthetic enhancement and practical vehicle edge protection. Highly sought after for their sleek appearance and corrosion resistance, these products are extensively applied across industries including car manufacturing, architectural decoration, and household appliances. As the demand for modern, clean-lined accents grows, u shape chrome trim strips not only serve as a visual upgrade but also as a functional safeguard against abrasion and impact. With global consumption accelerating, manufacturers are investing heavily in R&D and factory expansion to meet the robust market appetite for high-performance chrome trim strips.

Data-Driven Insights: Market Growth, Trends, and Export Statistics

Recent industry surveys highlight robust growth in the chrome trim strip market, driven predominantly by escalating automotive production and the rapid urbanization of emerging markets. According to Global Market Insights, Inc., the automotive trims segment experienced a CAGR of 8.5% from 2019 to 2023, reaching a global market volume exceeding 2 billion meters annually. Exporters have seen unprecedented upsurges, with leading u shape chrome trim strip exporter hubs in Asia-Pacific reporting export increases by 21% year-on-year in 2023.

The demand is not limited to automotive sectors. Construction and consumer electronics contributed to 26% of the overall usage, with expectations to cross 800 million meters by the close of 2024. The following table encapsulates recent market performance statistics:

| Year | Total Production (Million Meters) | Export Growth (%) | Top Application Sector (%) |

|---|---|---|---|

| 2019 | 1,450 | 5.2 | Automotive (62%) |

| 2020 | 1,610 | 6.5 | Automotive (59%) |

| 2021 | 1,800 | 11.2 | Automotive (58%) |

| 2022 | 1,910 | 18.8 | Automotive (54%) |

| 2023 | 2,030 | 21.0 | Automotive (53%) |

Technical Edge: Engineering and Manufacturing Excellence

Premium u shape chrome trim strip products are the result of advanced materials engineering and surface finishing techniques. Incorporating high-tenacity PVC or ABS as a base substrate, manufacturers deploy triple-layer chrome-plating using electrolytic or vacuum metallization processes. This approach ensures outstanding scratch-resistance, UV stability, and anti-yellowing capabilities, which extend the operational lifespan well beyond five years—even under severe weather exposure.

Technological enhancements include:

- High-precision roll forming for dimensional consistency ±0.05 mm

- Customizable hardness levels for varied bend radii and installation needs

- Optimized adhesive systems, from 3M foam tapes to advanced heat-activated glues for reliable bonding

- Environmental testing, guaranteeing RoHS and REACH compliance, increasingly demanded by EU and NA markets

Supplier Comparison: Factories, Exporters, and Product Diversity

Selecting a reliable u shape chrome trim strip factory or exporter is vital for ensuring product durability, timely shipment, and technical compliance. Industry benchmarks point to stark contrasts in capabilities, as highlighted in the following comparison table. The data below summarizes attributes of top manufacturers, with focus on production scale, customization scope, global certification, and value-added support:

| Factory/Exporter | Annual Output (Million Meters) | Custom Solutions | Certifications | Lead Time (Days) | Global Markets Served |

|---|---|---|---|---|---|

| TrimEdge Inc. | 320 | Extensive (Color, Size, Adhesive) | ISO 9001, REACH | 24 | North America, EU, MEA |

| Shenzhen ChromeTek | 260 | Medium (Profile, Finish) | RoHS, IATF-16949 | 19 | Asia-Pacific, EU |

| EuroPlastics Group | 415 | Selective (OEM only) | ISO 14001, UL | 32 | Europe, Americas |

| CustomLine Factories | 110 | High – Full Bespoke | REACH, SGS | 16 | Global |

Customization: Personalized Chrome Trim Solutions

The evolving customer expectations in the trim segment drive manufacturers to deliver a broad spectrum of customization. Suitable for demanding OEMs and architectural designers alike, options include:

- Color matching: Over 200 metallic and matte finishes developed for seamless integration with contemporary vehicle palettes or interior motifs.

- Profile engineering: Easy integration into tight corners, compound curves, and uneven substrates thanks to variable bend radii (from R5 to R70).

- Adhesive and attachment systems: Quick-apply, weather-resistant systems optimized for specific substrates such as glass, plastic, or painted surfaces.

- Length and sectional design: Custom spooling up to 50 meters per roll, straight sections, or pre-mitered parts for rapid assembly.

Application Spotlight: Projects and Industry Case Studies

u shape chrome trim strip applications extend far beyond standard automotive and architectural borders. In premium automotive production, trim strips are integrated as protective edges on door interiors and dashboards. A recent collaboration with a German luxury vehicle assembler resulted in a 19% reduction in assembly-line rejections due to improved strip flexibility and dimensional consistency.

The construction industry in the Middle East adopted customized chrome trim strips to line elevator interiors and lobby edges, increasing wear-resistance and design cohesion in luxury hotels. Consumer electronics manufacturers leverage miniaturized versions as elegant accent lines and device protectors, especially in tablets and smart appliances.

Quantitative results across projects show:

- Up to 25% reduction in visible scratching and chipping in high-touch zones.

- Installation time improved by 30%–45% when using pre-fitted adhesives.

- Customer satisfaction scores averaging 8.9/10, based on post-project surveys among automotive OEMs and commercial decorators.

Conclusion: Future Outlook for u shape chrome trim strip Solutions

With global markets emphasizing both aesthetics and performance, u shape chrome trim strip will remain at the forefront of design and protective solutions across diverse industries. Investment in sustainable materials, coupled with digitalized manufacturing, positions leading factories and exporters to outpace evolving regulatory and stylistic requirements. As consumer and commercial sectors broaden their usage scenarios, innovation in u shape chrome trim strip products stands poised to shape environments where function merges seamlessly with form—driving growth, efficiency, and value for years to come.

(u shape chrome trim strip)

FAQS on u shape chrome trim strip

Q: What is a U shape chrome trim strip?

A: A U shape chrome trim strip is a decorative and protective strip with a U-shaped cross-section and a shiny chrome finish. It is commonly used to enhance the appearance of automotive and furniture edges. Its flexible design allows easy installation on various surfaces.Q: How can I find a reliable U shape chrome trim strip exporter?

A: Look for exporters with strong track records, product certifications, and positive customer reviews. Reputable exporters often provide sample products and detailed specifications. Always check their experience as a u shape chrome trim strip exporter.Q: What should I look for in a U shape chrome trim strip factory?

A: Choose a factory with advanced manufacturing equipment, strict quality control, and the ability to offer customization. A reliable u shape chrome trim strip factory should also provide timely delivery and good after-sales service. Visiting the factory or requesting references enhances trust.Q: What are the main applications of U shape chrome trim strip products?

A: U shape chrome trim strip products are mainly used for vehicle door edges, furniture, mirrors, and decorative moldings. They offer protection from scratches and add a stylish chrome accent. Their versatility makes them popular in automotive and interior design industries.Q: Can U shape chrome trim strips be customized in size and finish?

A: Yes, manufacturers and exporters typically offer customization in length, width, and chrome finish. Custom u shape chrome trim strip products can match specific project requirements. Always confirm customization options with your supplier before ordering.-

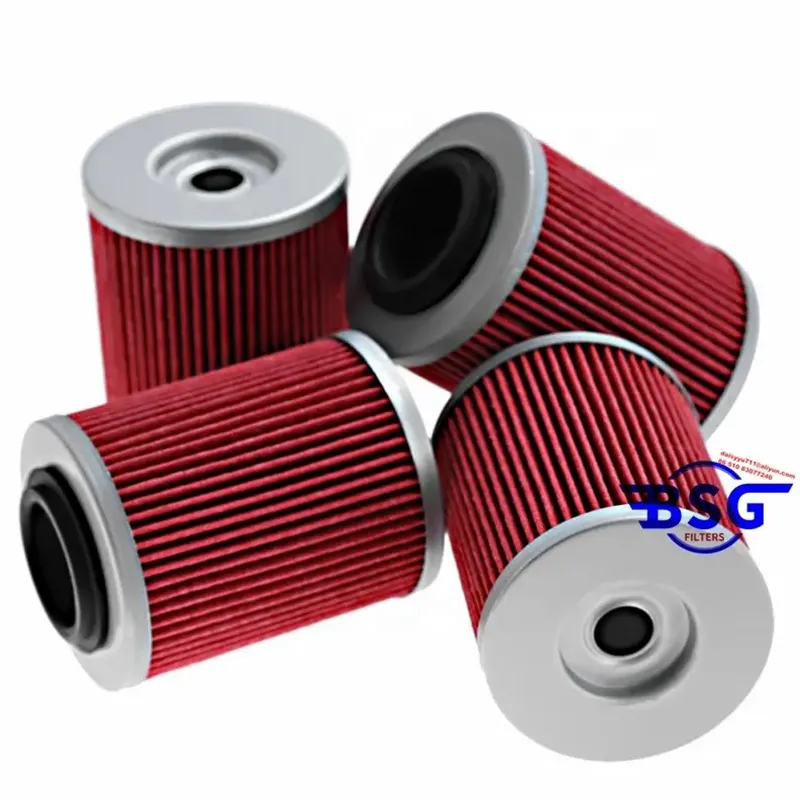

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025

-

Top Window Seal Strip Adhesive Companies - Durable & Reliable

NewsAug.18,2025

-

Leading Window Seal Strip Adhesive Solutions & Companies

NewsAug.17,2025

-

Tineco A10 A11 S11 S12 Vacuum Roller Brush & Pre-Hepa Filter

NewsAug.16,2025