extrusion silicone keder seg

નવેમ્બર . 17, 2024 06:43 Back to list

extrusion silicone keder seg

Understanding Extrusion Silicone Keder Segments Application and Benefits

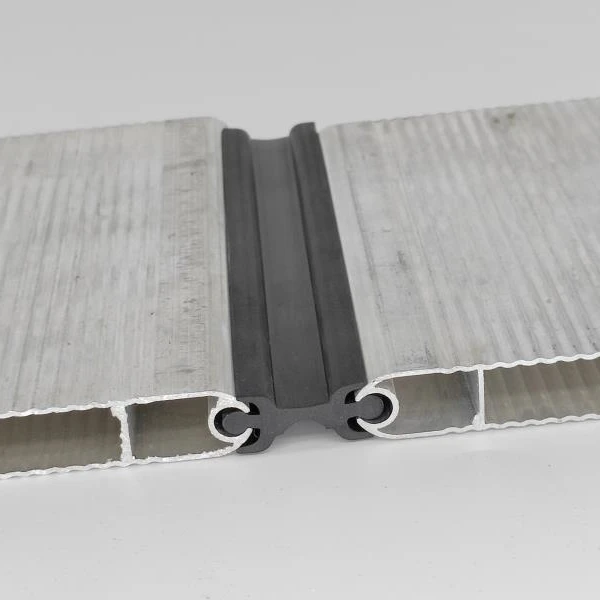

Extrusion silicone keder segments are increasingly gaining popularity in various industries due to their versatility, durability, and effectiveness in sealing applications. The term keder refers to a type of bead or cord that is typically used in the edges of fabrics, windows, and various material joints to create tight seals. This article explores the characteristics, applications, and advantages of silicone keder segments in different sectors.

What is Extrusion Silicone Keder?

Extrusion silicone keder is made from high-quality silicone rubber that is extruded to create a specific shape and dimension. These segments are designed with a reinforced profile that can easily fit into grooves, channels, or other designated areas where sealing is required. The extrusion process allows for consistent quality and uniformity, ensuring that every segment meets stringent manufacturing standards.

Silicone is chosen for the production of keder due to its excellent thermal and chemical resistance. This material can perform effectively in extreme temperatures, ranging from -60 degrees Celsius to 200 degrees Celsius. Additionally, silicone is UV-resistant, which makes it suitable for both indoor and outdoor applications where exposure to sunlight could degrade other materials.

Applications of Extrusion Silicone Keder

The applications of silicone keder segments are vast, spanning across multiple industries

1. Automotive Industry In the automotive sector, silicone keder segments are utilized in sealing windows, doors, and other openings to prevent air and water leaks. They help to reduce noise and vibrations within vehicles, enhancing comfort for passengers.

2. Aerospace In aerospace engineering, silicone keder is used to ensure that aircraft elements are tightly sealed, preventing moisture ingress and maintaining the integrity of crucial components against environmental factors.

3. Construction Silicone keder segments are used in the construction of buildings and installations, particularly where glass meets metal or other materials. The segments provide an essential seal to protect against weather elements, thus increasing the longevity and durability of structures.

extrusion silicone keder seg

5. Textile and Upholstery The textile industry often uses silicone keder for edge finishing on curtains, awnings, and upholstery items. It provides a neat finish while ensuring that the edges remain anchored and protected from fraying and wear.

Benefits of Using Extrusion Silicone Keder Segments

The advantages of using silicone keder segments over traditional materials are significant

- Durability Silicone rubber has an extended lifespan, which translates into lower maintenance costs and fewer replacements. - Flexibility Silicone keder segments offer excellent flexibility which allows them to adapt to different shapes and configurations, making installation easier.

- Chemical Resistance Silicone can withstand exposure to various chemicals, making it ideal for use in industrial settings where contact with oils, fuels, or solvents is likely.

- Environmental Resistance These segments are resistant to weather conditions, UV exposure, and ozone, which are critical factors in prolonging the use of materials in outdoor applications.

- Customizability Extrusion processes allow for customization in dimensions, hardness, and color, meeting specific project requirements effectively.

In conclusion, extrusion silicone keder segments present a reliable sealing solution across multiple industries, thanks to their durability, flexibility, and environmental resistance. As industries continue to prioritize quality and longevity in their products, the demand for silicone keder is expected to grow, underscoring the importance of this innovative material in modern applications. Whether used in construction, automotive, aerospace, maritime settings, or textiles, the benefits of silicone keder are clear, making them an essential component for a wide array of sealing needs.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025