Exploring the Leading Manufacturers of Flat Sealing Strips in the Industry Today

אוג . 06, 2024 12:21 Back to list

Exploring the Leading Manufacturers of Flat Sealing Strips in the Industry Today

The Importance and Role of Flat Sealing Strip Factories in Modern Manufacturing

In the contemporary manufacturing landscape, the significance of sealing solutions cannot be overstated, and flat sealing strips play a pivotal role in ensuring product integrity across a myriad of industries. Flat sealing strips, designed to create a barrier against environmental elements, are essential components in various applications, including automotive, construction, electronics, and appliances. This article delves into the importance of flat sealing strip factories in this dynamic landscape, shedding light on their contributions to innovation, quality, and sustainability.

Understanding Flat Sealing Strips

Flat sealing strips, often made from materials such as rubber, silicone, foam, or thermoplastic elastomers, are utilized to fill gaps and provide insulation against moisture, dust, air, and vibrations. Their design allows for versatility and adaptability, making them suitable for a wide range of applications. From sealing windows and doors in residential buildings to ensuring the airtight closure of automotive parts, these strips are crucial in enhancing the performance and lifespan of products.

The Role of Factories in Production

Flat sealing strip factories are at the forefront of the manufacturing process, employing advanced technologies and methodologies to produce high-quality sealing solutions. These factories typically utilize automated machinery combined with skilled labor to achieve precision in manufacturing. CNC machines, extrusion lines, and molding equipment are vital in producing sealing strips that not only meet but exceed industry standards.

Moreover, these factories invest significantly in research and development (R&D) to innovate and improve sealing technologies. As industries evolve, so do the demands for more effective sealing solutions. Implementing new materials and manufacturing techniques helps flat sealing strip factories stay competitive and cater to specific industry needs, whether it’s enhancing thermal resistance, improving durability, or optimizing cost-effectiveness.

Quality Assurance and Compliance

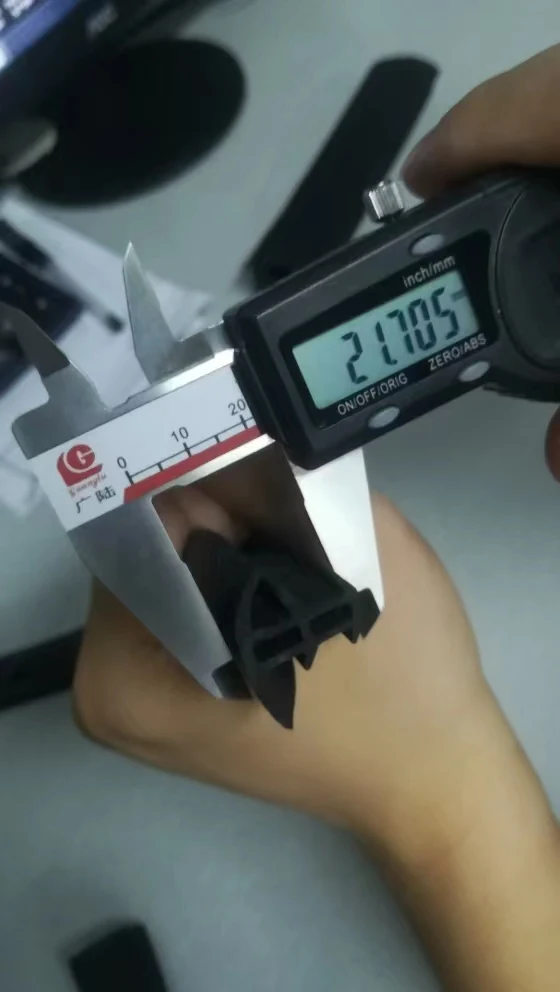

flat sealing strip factories

One of the most critical aspects of flat sealing strip production is quality assurance. Factories employ rigorous testing procedures to ensure that their products perform as expected under various conditions. This process often includes durability testing, compressibility tests, and environmental resilience evaluations. Factories are also required to comply with international quality standards, such as ISO and ASTM, which serve as benchmarks for the industry.

Quality assurance not only protects the reputation of the manufacturers but also assures customers that they are receiving reliable products. In industries where safety is paramount, such as automotive and aerospace, the quality of sealing strips can significantly impact overall system performance and safety.

Sustainability Considerations

In recent years, there has been a growing emphasis on sustainability within manufacturing processes. Flat sealing strip factories are increasingly adopting eco-friendly practices, such as utilizing recycled materials and reducing waste. By developing sealing strips that are not only high-performing but also environmentally friendly, these factories contribute to a more sustainable future.

Implementing energy-efficient manufacturing processes and minimizing carbon footprints has become a priority. Manufacturers are also exploring biodegradable materials, responding to global calls for more sustainable products that do not harm the environment.

Conclusion

Flat sealing strip factories play an indispensable role in modern manufacturing, delivering critical components that ensure product durability and integrity. Through continuous innovation, stringent quality assurance, and a commitment to sustainability, these factories are not only meeting the demands of various industries but also paving the way for a more resilient and eco-conscious manufacturing future. As industries continue to evolve with technological advancements, the importance of high-quality flat sealing strips will undoubtedly continue to grow, highlighting the crucial role of these factories in the supply chain.

-

Stretched Ceiling Keels in Various Shapes Durable & Custom Solutions

NewsMay.08,2025

-

Thin Silicone Strips for SEG Light Box Frames Durable & Customizable

NewsMay.08,2025

-

LED Integrated Neon Lights - High-Brightness & Energy-Efficient Solutions

NewsMay.07,2025

-

High-Quality Sponge Door Seals Durable & Custom Solutions

NewsMay.07,2025

-

Premium Aluminum Channel/Groove Edge Products Manufacturer & Exporter

NewsMay.07,2025

-

Precision 3D Channel Aluminum Slot Tape Durable & Custom Solutions

NewsMay.07,2025