Price and Supplier Information for Strip Seal Expansion Joints in Construction Industry

Aug . 15, 2024 09:29 Back to list

Price and Supplier Information for Strip Seal Expansion Joints in Construction Industry

Exploring the Pricing and Supply Dynamics of Strip Seal Expansion Joints

The construction and civil engineering industries continually seek innovative solutions to address the challenges posed by various environmental and mechanical factors. One such solution is the strip seal expansion joint, a vital component in bridge construction, highways, and building facades. As infrastructure projects grow in scale and complexity, understanding the price dynamics and supplier options for strip seal expansion joints becomes increasingly important for engineers and project managers.

What is a Strip Seal Expansion Joint?

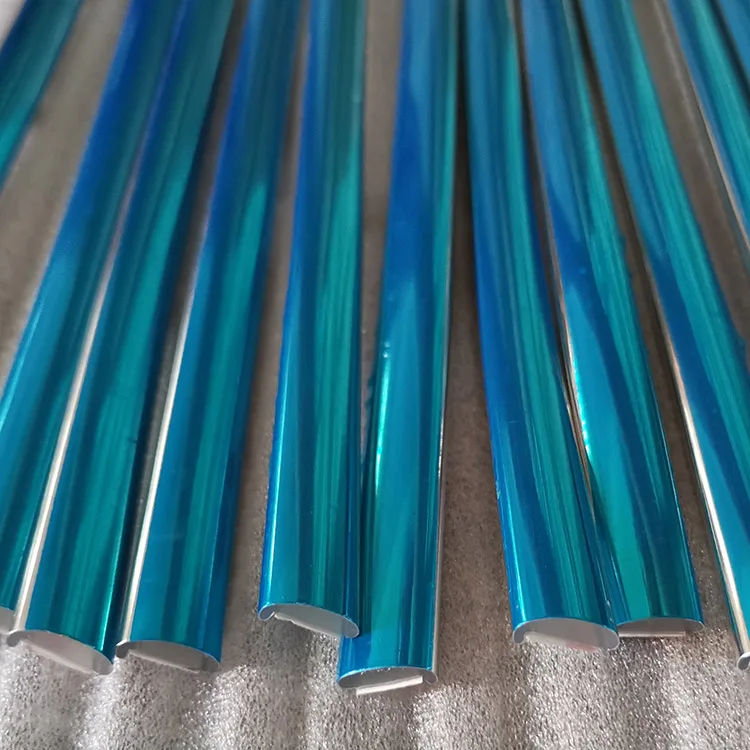

Strip seal expansion joints are designed to accommodate movement in structures due to temperature changes, traffic loads, and seismic activities. They are typically composed of two main components a flexible rubber seal and a metal support system. The rubber seal is inserted into a longitudinal slot created in the deck, allowing for the expansion and contraction of the materials without compromising structural integrity. This flexibility is crucial in preventing damage to the surrounding structure, which can arise from the movement.

Factors Influencing Prices

Several factors influence the pricing of strip seal expansion joints. The first is the material quality. High-performance strips made from durable elastomers and stainless steel may carry a higher price tag but offer better longevity and resistance to harsh environmental conditions. The size and design complexity of the joint also significantly impact costs. Custom designs tailored to specific project needs can lead to increased manufacturing and installation expenses.

Moreover, market conditions play a pivotal role. Prices for raw materials like rubber and steel fluctuate based on global supply chains, trade agreements, and geopolitical conditions. Recent trends show that suppliers are increasingly affected by global supply chain disruptions, which can lead to spikes in material costs and, consequently, the final price of expansion joints.

strip seal expansion joint price supplier

Supplier Dynamics

The choice of supplier is critical. A reliable supplier not only provides competitively priced products but also delivers timely support and service. Companies looking for strip seal expansion joints have several options, ranging from local manufacturers to international suppliers. Each has its pros and cons; local suppliers may offer shorter lead times and easier communication, while larger manufacturers might provide a wider range of products and potentially lower prices due to economies of scale.

It's also essential to evaluate a supplier's reputation in the industry. Established suppliers often have extensive experience and customer feedback, which can guide purchasing decisions. Engaging in long-term relationships with reputable suppliers can lead to better pricing agreements, especially for bulk orders or repeated projects.

The Importance of Cost-Effectiveness

While obtaining competitive prices is crucial, the overall cost-effectiveness of the selected strip seal expansion joint must also be considered. The initial cost is only one aspect of the total investment; durability, maintenance requirements, and life expectancy should also be weighed. In many cases, selecting a slightly more expensive but higher-quality joint can lead to significant savings over time due to lower maintenance costs and longer replacement intervals.

Conclusion

In summary, the pricing and supply dynamics of strip seal expansion joints are shaped by various factors, including material quality, market conditions, design complexity, and supplier reliability. As infrastructure projects continue to evolve, it is imperative for engineers and project managers to consider not only the upfront costs but also the long-term implications of their material choices. By conducting thorough research and fostering relationships with reputable suppliers, stakeholders can ensure that they achieve both performance and cost-effectiveness in their construction projects.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025