Soft Plastic Aluminum Trim Manufacturing Facilities and Their Production Processes

lis . 11, 2024 18:30 Back to list

Soft Plastic Aluminum Trim Manufacturing Facilities and Their Production Processes

The Rise of Soft Plastic Aluminum Trim Factories Revolutionizing Modern Design

In recent years, the demand for innovative materials in various industries has surged, prompting manufacturers to develop new solutions that combine functionality with aesthetic appeal. Among these advancements is the emergence of soft plastic aluminum trim factories, which are redefining the way products are designed and produced. This article explores the significance, advantages, and applications of soft plastic aluminum trims, shining a light on the factories that produce them.

Understanding Soft Plastic Aluminum Trim

Soft plastic aluminum trim is a composite material that combines the lightweight and strength of aluminum with the flexibility and versatility of soft plastics. This unique combination creates a material that can be molded into various shapes and sizes while maintaining durability and resistance to wear. The soft plastic layer can be easily customized by adding colors, finishes, and textures, making it an attractive option for manufacturers aiming to enhance the aesthetic appeal of their products.

The Advantages of Soft Plastic Aluminum Trim

1. Durability The aluminum component provides substantial strength and longevity, making it ideal for both indoor and outdoor applications. Unlike traditional plastic trims that may crack or fade under environmental stress, soft plastic aluminum trims are built to withstand challenging conditions.

2. Versatility One of the most significant advantages of soft plastic aluminum trim is its versatility. This material can be utilized in a wide range of industries, from automotive to construction, and even furniture design. Manufacturers can create intricate designs tailored to specific needs, which enhances the overall functionality of their products.

3. Aesthetic Appeal Soft plastic aluminum trims offer endless design possibilities. With the ability to choose from various colors, finishes, and shapes, manufacturers can produce visually stunning products that captivate consumers. This aesthetic flexibility allows businesses to differentiate themselves in competitive markets.

4. Sustainability Many factories are focusing on environmentally friendly manufacturing processes, using recyclable materials and energy-efficient practices. Soft plastic aluminum trims can often be produced in a way that minimizes waste, contributing to a more sustainable production cycle.

The Role of Factories in Production

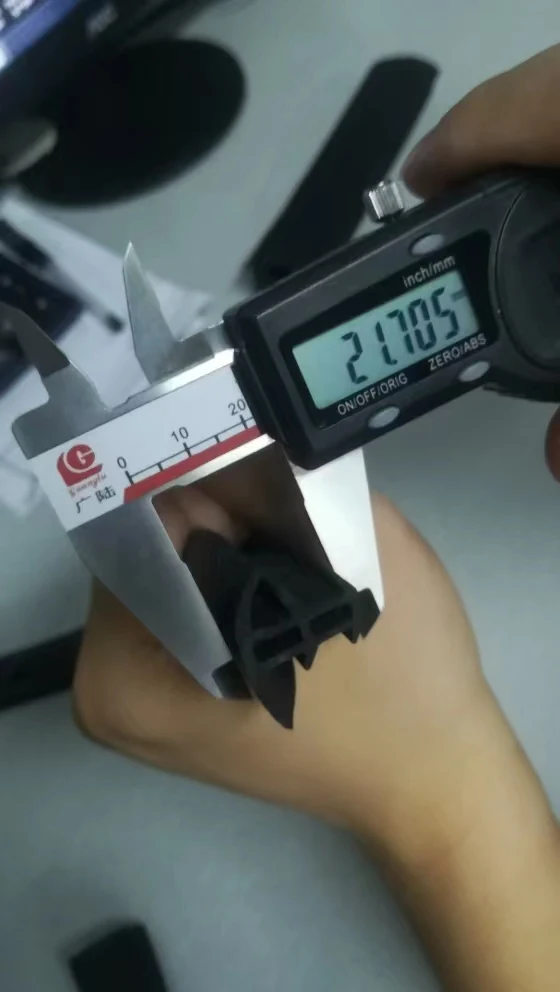

soft plastic aluminum trim factories

The growth of soft plastic aluminum trim factories is a response to the increasing demand for high-quality, durable materials. These factories employ advanced technologies, such as injection molding and extrusion, to efficiently create products that meet industry standards.

In a typical soft plastic aluminum trim factory, raw materials are sourced responsibly, ensuring that only the best components are used in production. Skilled technicians oversee the manufacturing process, optimizing settings for precision and quality control. As industries continue to evolve, these factories are at the forefront, adapting to emerging trends and consumer needs.

Applications of Soft Plastic Aluminum Trim

The applications of soft plastic aluminum trims are extensive

- Automotive Industry In vehicles, trims can be found on dashboards, door panels, and exterior moldings, enhancing both functionality and aesthetics.

- Construction Building structures often use these trims for window frames, door casings, and interior finishes, providing a modern look that is both practical and stylish.

- Furniture Design Designers are incorporating soft plastic aluminum trims into furniture pieces to achieve sleek designs that are easy to maintain.

- Consumer Electronics The technology sector benefits from this material for product housings and decorative features that require strength without added weight.

Conclusion

The rise of soft plastic aluminum trim factories marks a significant milestone in material innovation. As industries continue to prioritize durability, design, and sustainability, these factories are well-positioned to lead the way in creating groundbreaking products. Whether it’s in the automotive sector, construction, or consumer electronics, the soft plastic aluminum trim is set to become an integral part of modern design practices, offering a blend of form and function that caters to the evolving tastes and needs of consumers worldwide.

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025

-

Top Window Seal Strip Adhesive Companies - Durable & Reliable

NewsAug.18,2025

-

Leading Window Seal Strip Adhesive Solutions & Companies

NewsAug.17,2025