Exploring Manufacturing Options for 50m LED Neon Light Solutions

Aug . 20, 2024 14:01 Back to list

Exploring Manufacturing Options for 50m LED Neon Light Solutions

The Rise of LED Neon A Look into 50m Factories

In recent years, LED neon lighting has taken the world by storm, becoming a staple in both commercial and residential settings. As demand for this vibrant and energy-efficient lighting continues to grow, factories dedicated to producing LED neon strips, particularly those measuring 50 meters and beyond, have emerged as key players in the market. This article explores the significance of 50m LED neon factories, their production processes, and their impact on the lighting industry.

Understanding LED Neon Technology

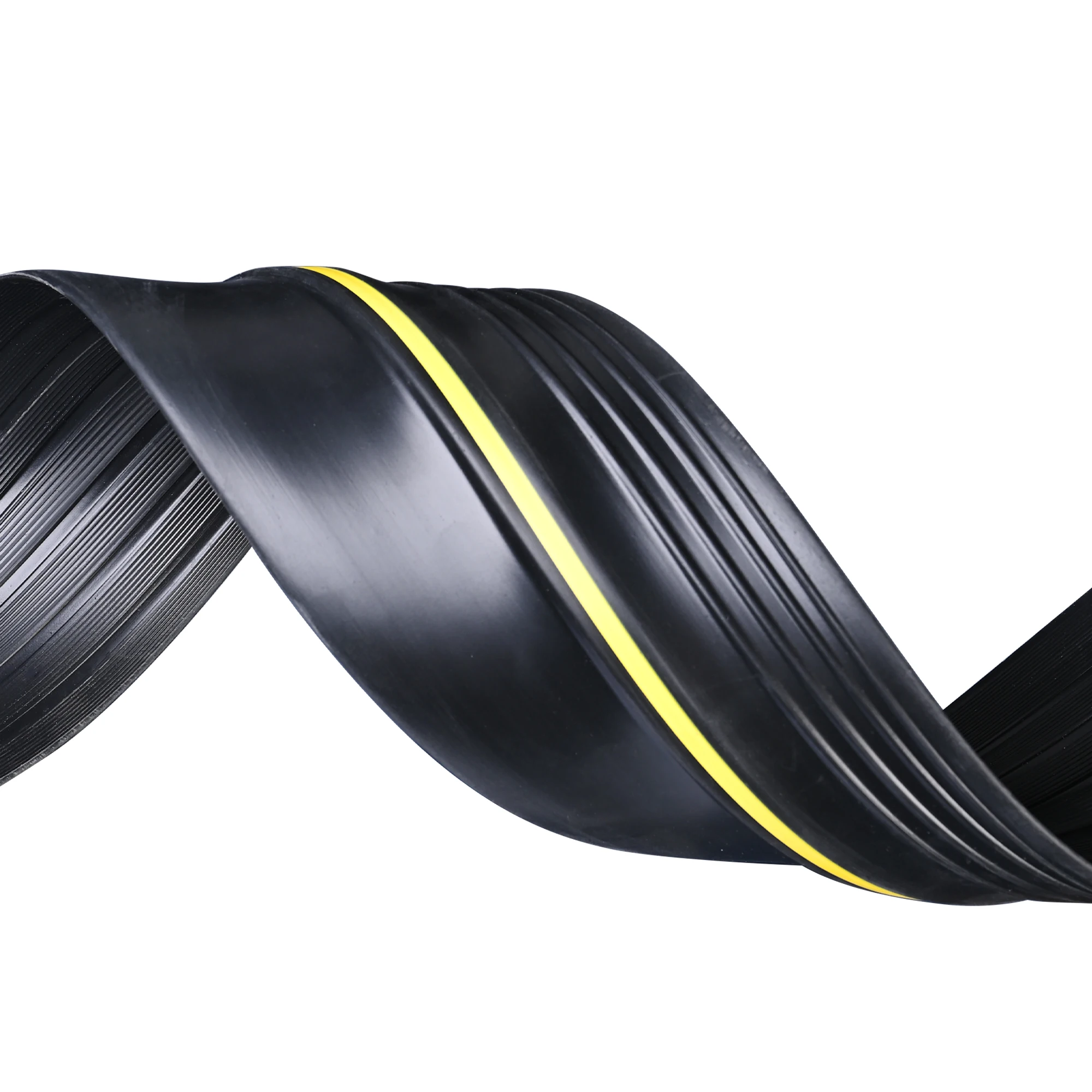

LED neon lights, known for their flexibility and vivid colors, are a modern alternative to traditional glass neon signs. These lights utilize light-emitting diodes (LEDs) encased in a silicone tube, making them more durable, energy-efficient, and safer than their gas-filled counterparts. Given their versatility, LED neon is favored for a variety of applications, from advertising displays and event decorations to home interiors and artistic installations.

The production of LED neon lights involves several stages, from gathering raw materials to the final assembly of the lighting strips. Factories equipped to produce LED neon strips in longer lengths, such as 50 meters, can cater to a wide array of client needs, making them particularly attractive to businesses looking for customized solutions.

The Production Process

The manufacturing of 50m LED neon lights begins with the sourcing of high-quality LED chips, which are the heart of the lighting system. These chips are then mounted on flexible printed circuit boards (PCBs), allowing for the creation of continuous strips. The next step involves encasing the LEDs in robust silicone tubing, which not only protects the lights but also enhances their aesthetic appeal by providing a smooth, uniform glow.

led neon-50m factories

Quality control is an essential aspect of the production process. Factories often employ advanced testing equipment to ensure each strip meets safety and performance standards before they are packaged for distribution. This meticulous attention to detail results in products that boast longer lifespans and lower energy consumption, further solidifying the appeal of LED neon lighting.

The Impact on the Market

The rise of 50m LED neon factories has had a significant impact on the market, both in terms of supply and innovation. These factories enable mass production, drastically reducing costs and making LED neon lighting more accessible to consumers and businesses alike. As the technology has matured, factories have also been able to innovate, introducing new colors, effects, and control systems compatible with smart home technologies.

Moreover, the environmental benefits of LED neon lighting cannot be overstated. Compared to traditional lighting options, LED neon uses significantly less electricity and has a longer lifespan, reducing waste. As sustainability becomes a core focus for many industries, the proliferation of 50m LED neon factories aligns perfectly with the growing demand for eco-friendly products.

Conclusion

The emergence of 50m LED neon factories marks a transformative moment in the lighting industry. By combining efficiency with creativity, they have opened new avenues for design and application, allowing businesses and individuals to illuminate their spaces in innovative ways. As technology continues to progress, these factories will likely play an increasingly crucial role in shaping the future of lighting, making LED neon a prominent feature in our everyday lives. The blend of style, efficiency, and sustainability offered by LED neon will undoubtedly ensure its place at the forefront of lighting solutions for years to come.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025