flat aluminum coil

dec . 27, 2024 06:20 Back to list

flat aluminum coil

Exploring Flat Aluminum Coils A Versatile Material for Modern Applications

Flat aluminum coils, known for their exceptional strength-to-weight ratio and corrosion resistance, have emerged as a pivotal material in numerous industries. This article delves into the properties, production, applications, and advantages of flat aluminum coils, showcasing why they are becoming increasingly popular in today’s industrial landscape.

Properties of Flat Aluminum Coils

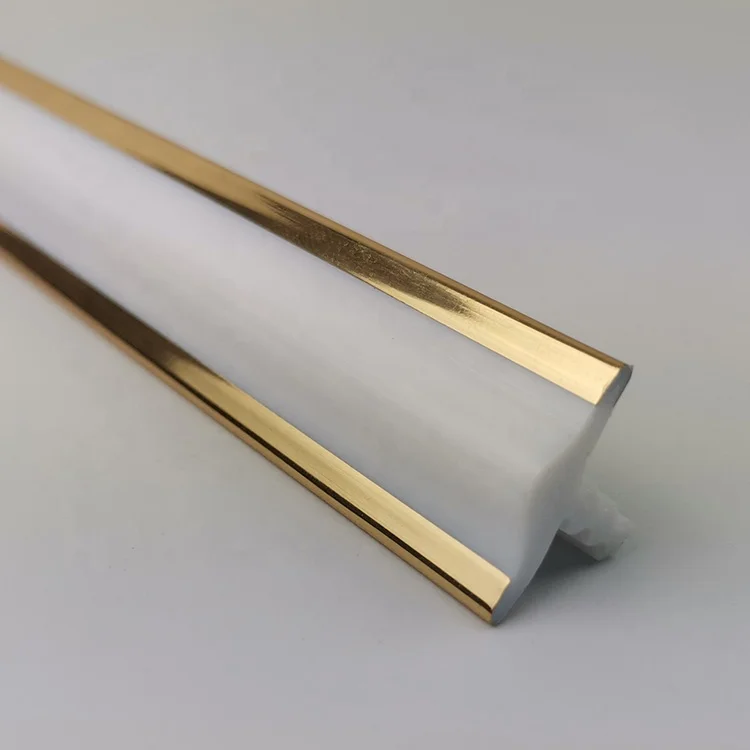

Flat aluminum coils are produced through a rolling process where large aluminum ingots are flattened into thin sheets or coils. Their versatility stems from their lightweight nature, making them an attractive option for applications that require durable materials without the additional weight of steel or other metals. The aluminum used can vary in alloys, with 1100, 3003, 5052, and 6061 being among the most common, offering diverse mechanical properties that cater to specific needs.

One of the standout features of flat aluminum coils is their resistance to corrosion. Aluminum naturally forms a protective oxide layer when exposed to the atmosphere, which inhibits further oxidation and degradation. This characteristic makes aluminum coils ideal for outdoor applications and environments that experience high moisture levels.

Production Process

The production of flat aluminum coils involves several critical steps, ensuring the final product meets industry standards for quality and performance. The process begins with melting aluminum ingots, followed by casting them into large slabs. These slabs are then heated and passed through large rollers in a series of processes called hot rolling. After reaching the desired thickness, the aluminum slabs undergo cold rolling, which further refines the gauge and enhances surface quality.

Once the desired thickness is achieved, the coils are typically subjected to various treatments, including annealing and coating. Annealing is a heat treatment process that softens the aluminum, making it more malleable, while coatings can provide additional surface protection, enhance aesthetics, or impart specific properties like increased durability or reflectivity.

Applications of Flat Aluminum Coils

flat aluminum coil

The versatility of flat aluminum coils opens up a wide array of applications across different industries. In the automotive sector, they are used for manufacturing components such as hoods, fenders, and interior panels due to their lightweight nature, which contributes to fuel efficiency without compromising on strength.

The construction industry also utilizes flat aluminum coils extensively. They are commonly found in roofing, siding, and window frames, where their resistance to corrosion and low maintenance requirements make them ideal for long-term structural integrity. Additionally, aluminum coils are prevalent in HVAC systems, where they serve as components in heat exchangers and ducting systems due to their excellent thermal conductivity.

In the packaging industry, aluminum coils are utilized for producing foil and lids, which are valued for their barrier properties, helping to preserve food quality while providing an attractive presentation.

Advantages of Flat Aluminum Coils

The growing adoption of flat aluminum coils can be attributed to several key advantages. Firstly, their lightweight nature translates to easier handling and transportation, reducing logistical costs. Secondly, the durability and corrosion resistance of aluminum mean longer lifespans for products made from aluminum coils, leading to lower replacement and maintenance costs over time.

Furthermore, aluminum’s recyclability is a significant advantage in today’s environmentally conscious market. Flat aluminum coils can be recycled multiple times without losing their properties, contributing to sustainability efforts and reducing the carbon footprint associated with material production.

Conclusion

In summary, flat aluminum coils represent a dynamic and essential material used across various industries. Their unique combination of lightweight strength, corrosion resistance, and versatility ensures that they meet the demanding requirements of modern applications. As industries continue to innovate and adapt to changing market needs, flat aluminum coils will undoubtedly play a vital role in shaping the future of manufacturing and construction, reinforcing their position as a cornerstone of modern material science.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025