windshield seal strip factory

Nov . 06, 2024 11:06 Back to list

windshield seal strip factory

Understanding Windshield Seal Strips Importance and Manufacturing Insights

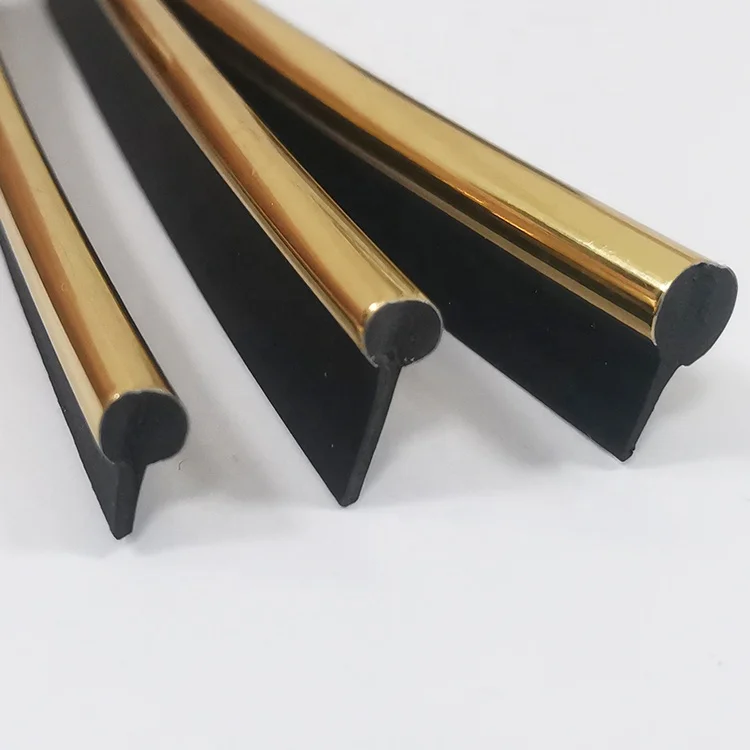

Windshield seal strips play a crucial role in automotive safety and performance, often overlooked by both manufacturers and consumers. These components, typically made from rubber or a similar material, serve as a barrier between the windshield and the frame of the vehicle. Their primary function is to provide a watertight seal, preventing water, air, and dust from entering the car, while also contributing to the overall structural integrity of the windshield.

Understanding Windshield Seal Strips Importance and Manufacturing Insights

During the production process, manufacturers typically begin with mixing compounds that include natural and synthetic rubber, along with additives that enhance performance characteristics. This mixture is then extruded into the desired shape of the seal strip. Extrusion allows for uniformity and precision, ensuring that each strip meets the exact specifications required for a proper fit on different vehicle models.

windshield seal strip factory

After extrusion, the seal strips undergo a curing process, where they are heated to form a solid and resilient product. This curing stage is critical, as it affects the material's hardness, flexibility, and overall performance. Quality control measures are rigorously implemented at various stages of production, with tests conducted to assess the seal’s longevity, elasticity, and resistance to environmental factors.

An essential aspect of manufacturing windshield seal strips is understanding the different requirements for various vehicle types. For example, high-performance vehicles may require specialized seal strips that can endure higher speeds and prevent wind noise more effectively, while standard sedans might have more basic requirements. Therefore, factories often focus on producing a range of profiles and sizes to accommodate diverse automotive needs.

Eco-friendly practices are increasingly being integrated into the production processes of windshield seal strip factories. Many manufacturers are now exploring biocompatible materials and recycling options to minimize waste and reduce their environmental impact. This shift not only meets the growing consumer demand for sustainable practices but also aligns with global trends toward greener manufacturing.

In conclusion, windshield seal strips are integral components that enhance the functionality and reliability of vehicles. The meticulous manufacturing process, from raw material selection to quality control, underscores the importance of these components in automotive design. As the industry evolves, innovations in materials and eco-friendly practices will continue to shape the future of windshield seal strip production, ensuring that they remain effective in providing safety and comfort for drivers and passengers alike.

-

Top Window Seal Strip Adhesive Companies for Durable Solutions

NewsJul.27,2025

-

Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter

NewsJul.26,2025

-

Factory Hot Sale Recycled Green Elastic Profiles Wholesale Supplier

NewsJul.25,2025

-

Hi flo Oil Filter H F155 for KT M 250 EXC Racing 2003-2006, OEM Quality

NewsJul.24,2025

-

Top LED Neon Rope Light Outdoor Companies – Durable & Weatherproof Solutions

NewsJul.23,2025

-

Top Window Seal Strip Adhesive Companies for Quality Sealing Solutions

NewsJul.22,2025