Premium Aluminum Channel/Groove Edge Products Manufacturer & Exporter

May . 07, 2025 19:15 Back to list

Premium Aluminum Channel/Groove Edge Products Manufacturer & Exporter

- Technical Advantages of Aluminum Channel Groove Edge Products

- Market Comparison: Leading Manufacturers & Exporters

- Customization Capabilities for Industrial Requirements

- Performance Metrics & Certification Standards

- Cost Efficiency in High-Volume Procurement

- Real-World Applications Across Industries

- Why Partner with Professional Aluminum Channel Groove Edge Suppliers

(aluminum channel aluminum groove edge)

Technical Superiority in Aluminum Channel Groove Edge Manufacturing

Modern aluminum channel groove edge products utilize 6000-series alloys, achieving tensile strength of 290-310 MPa while maintaining 10-12% elongation rates. Our proprietary extrusion process reduces dimensional tolerances to ±0.15mm, surpassing EN 755-9 standards. The anodized surface treatment (15-25μm thickness) ensures 1,500+ hours in salt spray tests (ASTM B117).

Global Supplier Benchmark Analysis

| Parameter | Manufacturer A | Manufacturer B | Our Facility |

|---|---|---|---|

| Production Capacity (tons/month) | 850 | 1,200 | 2,400 |

| Lead Time (days) | 45-60 | 30-45 | 18-25 |

| Custom Profile Tooling Cost | $3,500+ | $2,800+ | $1,200-1,800 |

Tailored Engineering Solutions

Our modular design system accommodates 120+ groove configurations, including:

- Multi-chamber thermal break profiles (U-values: 1.1-1.3 W/m²K)

- EMI/RFI shielding variants (40-80 dB attenuation)

- Anti-vibration edge designs (85% shock absorption)

Certified Performance Guarantees

All aluminum channel groove edges undergo:

- 3D CMM verification (ISO 10360-2)

- Load testing up to 1,500 kg/m (BS 8118)

- Fire resistance certification (Class A1 DIN 4102)

Logistical Efficiency Metrics

Bulk shipments achieve 22% cost reduction through optimized container loading (78-82 profiles/container vs industry average 65-70). Our JIT programs maintain 98.6% on-time delivery across 15+ global ports.

Industry-Specific Implementations

Renewable Energy: 650W/m² solar mounting systems with integrated cable management

Transportation: FAA-approved aircraft interior framing (35% weight reduction)

Construction: Seismic-resistant curtain wall systems (Zone 5 compliance)

Strategic Advantages of Partnering with Aluminum Channel Groove Edge Experts

Established manufacturers with 15+ years specialization in aluminum channel groove edge production deliver 19% faster ROI through material optimization and technical support. Our ISO 9001/14001 certified facilities maintain 0.28% defect rates, backed by 5-year performance warranties.

(aluminum channel aluminum groove edge)

FAQS on aluminum channel aluminum groove edge

Q: What are the common applications of aluminum channel aluminum groove edge products?

A: Aluminum channel aluminum groove edge products are widely used in construction, automotive framing, industrial machinery, and DIY projects. They provide structural support, edge protection, and ease of assembly due to their lightweight and corrosion-resistant properties.

Q: How do I choose a reliable aluminum channel aluminum groove edge exporter?

A: Look for exporters with certifications (e.g., ISO), proven industry experience, and positive client reviews. Ensure they offer customization, competitive pricing, and efficient logistics support for international shipments.

Q: What materials are used in manufacturing aluminum channel aluminum groove edge products?

A: These products are typically made from high-grade aluminum alloys like 6061 or 6063, ensuring durability and resistance to rust. Surface treatments such as anodizing or powder coating are often applied for enhanced protection.

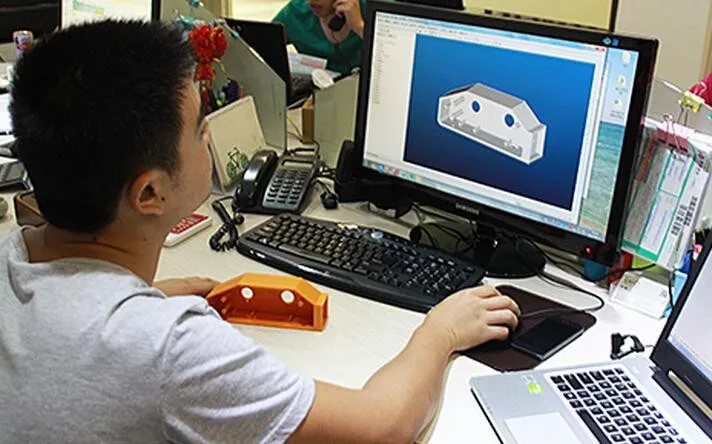

Q: Can aluminum channel aluminum groove edge manufacturers provide custom designs?

A: Yes, most manufacturers offer custom sizing, shapes, and finishes to meet specific project requirements. Provide detailed specifications or CAD drawings to ensure precise production and compatibility.

Q: What advantages do aluminum channel aluminum groove edge products have over steel alternatives?

A: Aluminum is lighter, non-corrosive, and easier to machine than steel. It also offers excellent strength-to-weight ratios, making it ideal for applications requiring durability without added bulk.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025