custom polymer material

ធ្នូ . 23, 2024 11:24 Back to list

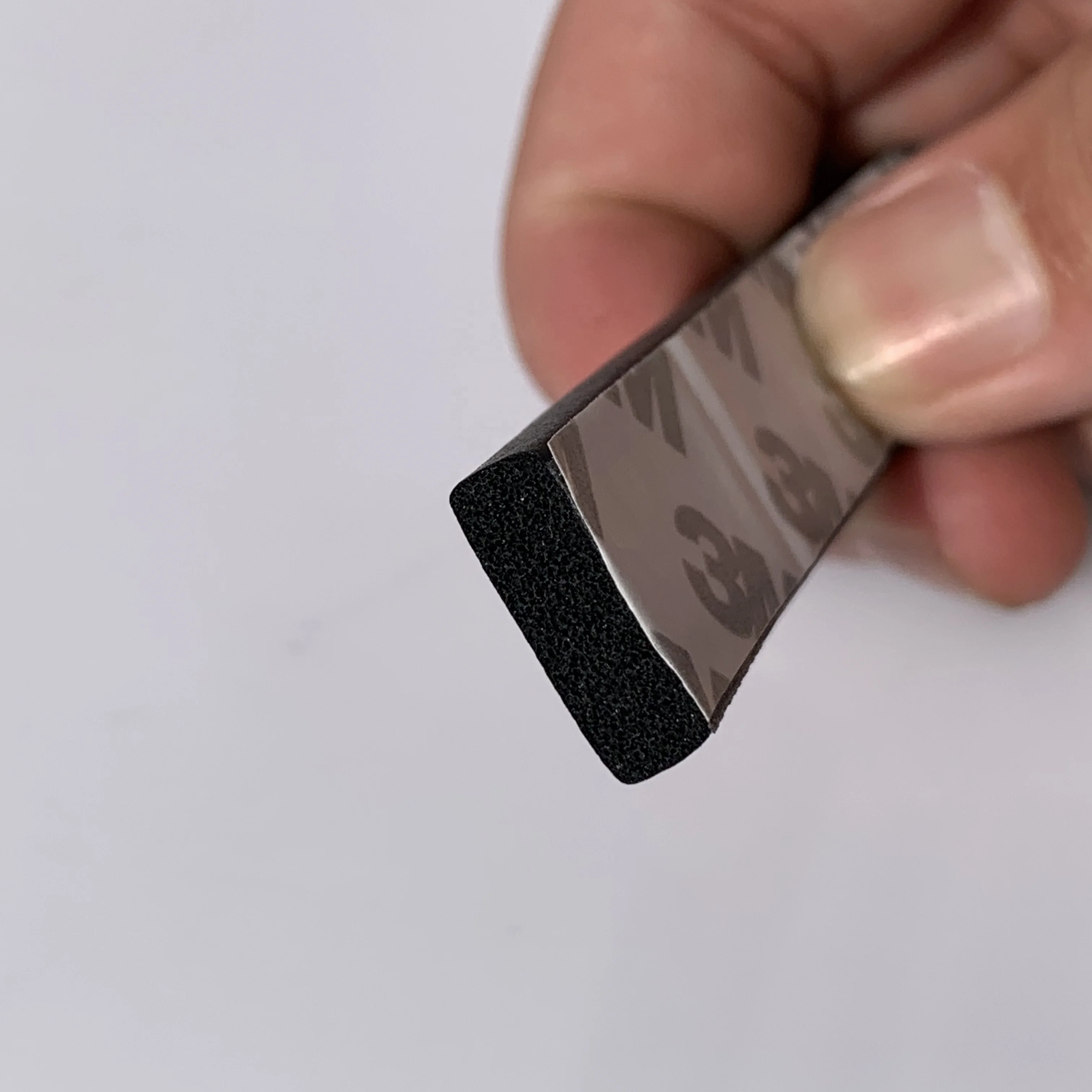

custom polymer material

Custom Polymer Materials Innovative Solutions for Diverse Applications

In today’s fast-paced technological world, the demand for customized materials is growing exponentially. One of the most versatile and widely used types of materials in various industries is polymers. Custom polymer materials offer a unique solution to meet specific requirements across different applications, enhancing performance, durability, and functionality.

Polymers are compounds made up of repeating structural units called monomers, and they can be tailored to possess a wide range of properties. This tailoring process allows manufacturers to create custom polymers that meet the precise needs of specific applications. Whether it involves adjusting the polymer's chemical composition to enhance strength and flexibility, or modifying its thermal and electrical properties for specific environments, customization is key to maximizing performance.

One of the most significant benefits of custom polymer materials is their ability to enhance product performance. For industries such as automotive, aerospace, medical, and consumer goods, the performance characteristics of materials can directly impact the efficiency, safety, and reliability of products. For instance, in the automotive sector, custom polymers can be developed to withstand extreme temperatures and pressures, contributing to lighter and more fuel-efficient vehicles. Similarly, in the medical field, customized polymer materials can be designed to be biocompatible and corrosion-resistant, essential for medical implants and devices that interact with the human body.

Moreover, custom polymers can be engineered for specific environmental conditions. For example, materials exposed to harsh chemicals or extreme weather conditions may require polymers that demonstrate superior resistance to degradation. Customization allows for the incorporation of additives or reinforcements that can improve a polymer’s chemical resistance, UV stability, or mechanical strength, ensuring longevity and reliability in challenging environments.

custom polymer material

The versatility of custom polymer materials also extends to their aesthetic properties. Industries such as electronics, fashion, and interior design benefit from polymers that can be colored, textured, and shaped in innovative ways. Customization can lead to unique designs that appeal to consumers, allowing brands to differentiate themselves in competitive markets. This aesthetic adaptability can also be fundamental in applications such as packaging, where visual appeal is intertwined with functionality.

Additionally, advancements in technology have facilitated the development of custom polymers through processes such as 3D printing and additive manufacturing. These technologies allow for rapid prototyping and production, enabling companies to quickly bring products to market while minimizing waste and reducing costs. Custom polymers can be designed and fabricated on-demand, catering to the evolving needs of businesses and consumers alike.

Sustainability is another vital element in the production of custom polymer materials. As industries strive to reduce their environmental footprint, the development of bio-based and recyclable polymers is becoming increasingly critical. Custom polymer formulations can incorporate renewable materials, reducing reliance on fossil fuels and promoting sustainability. By choosing environmentally friendly options, companies can enhance their brand image while addressing consumer concerns regarding sustainable practices.

In conclusion, custom polymer materials are essential in driving innovation across various industries. Their adaptability, performance enhancements, and aesthetic possibilities make them ideal for tailored applications in automotive, aerospace, medical, and consumer goods. As technology continues to advance, the role of custom polymers in shaping the future of materials science will only grow, paving the way for smarter, more efficient solutions for complex challenges. By embracing custom polymer materials, businesses can ensure they remain at the forefront of innovation while meeting the diverse needs of their customers and the environment.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025