hand use”strips manufacturer

វិច្ឆិកា . 11, 2024 10:34 Back to list

hand use”strips manufacturer

The Importance of Hand Use in Strips Manufacturing

Strips manufacturing is a pivotal industry that serves a variety of sectors, including automotive, construction, and electronics. As technology continues to advance, the need for precision and efficiency in manufacturing processes has never been more pronounced. One of the critical aspects of this industry is the role of hand use in the production of strips. This article explores the importance of manual skills in strips manufacturing, the benefits they offer, and the balance between human labor and automation.

The Role of Hand Use in Manufacturing

Despite the rise of automation and robotics in manufacturing, hand use remains an essential part of strips production. Manual skills contribute to the intricate processes involved in creating high-quality strips, from cutting and bending to assembly and finishing. Skilled workers bring a level of precision and creativity that machines cannot replicate entirely. Furthermore, the tactile feedback that comes from manual labor allows workers to make nuanced adjustments, ensuring that the final product meets stringent quality standards.

In strips manufacturing, hand use is particularly relevant in processes that require fine detailing or adjustments based on real-time observations. For example, when producing custom strips tailored to specific client needs, skilled labor is often essential. Workers are capable of interpreting design specifications and making on-the-fly modifications, a flexibility that machines may lack.

Benefits of Hand Use in Strips Manufacturing

1. Quality Assurance One of the key benefits of incorporating hand use in strips manufacturing is the enhanced quality control that comes with human intervention. Workers trained in quality assurance can easily detect flaws or inconsistencies that automated systems might overlook. Their ability to conduct manual inspections ensures that every strip produced meets the necessary standards, ultimately leading to fewer returns and enhanced customer satisfaction.

2. Adaptability to Client Needs The ability to make rapid adjustments based on client feedback or specific project requirements is critical in today's fast-paced market. Manual skills allow workers to adjust production lines and create bespoke items, providing a level of customization that automated systems may struggle to achieve. As clients demand more individualized products, the value of skilled manual labor grows.

hand use”strips manufacturer

3. Cost-Effectiveness While automation can reduce labor costs in the long run, initial investments in machinery can be prohibitive for smaller manufacturers. By integrating hand use into their production processes, companies can reduce upfront expenditures, allowing them to remain competitive while still delivering high-quality strips.

4. Employee Morale and Job Satisfaction Incorporating hand use in manufacturing processes can also lead to increased job satisfaction among workers. Skilled labor can foster a sense of accomplishment and pride in craftsmanship that might be absent in more automated environments. Empowering employees to take ownership of their work can lead to higher morale and lower turnover rates.

Striking a Balance Between Automation and Hand Use

While hand use is vital, it is important to recognize that the future of strips manufacturing lies in finding a harmonious balance between manual labor and automation. Advanced technologies, such as CNC machines and robotics, can handle repetitive tasks, allowing skilled workers to focus on more complex aspects of production. This synergy not only enhances productivity but also drives innovation within the industry.

To prepare for this balance, manufacturers must invest in training and developing their workforce. By upskilling employees to work alongside advanced machinery, companies can create a versatile team that can adapt to the evolving demands of the industry. Continuous education and training programs can equip workers with the necessary skills to thrive in an increasingly automated environment.

Conclusion

Hand use in strips manufacturing plays a crucial role in ensuring quality, adaptability, and employee satisfaction. While the shift toward automation is undeniable, the value of skilled manual labor must not be underestimated. By striking a balance between technology and hand use, manufacturers can enhance their production processes, meet client demands, and contribute to a thriving workforce. Ultimately, preserving the human touch in manufacturing will continue to be a defining factor in the success of the strips industry.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

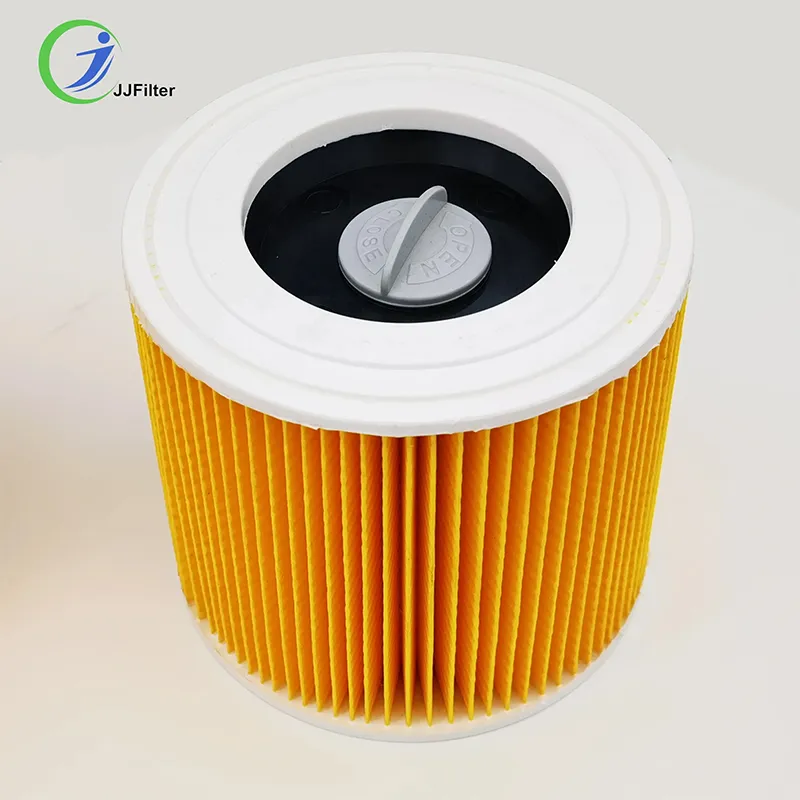

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025