OEM Flat Keder Edge PVC Welt Strip for Custom Upholstery and Trailers

វិច្ឆិកា . 07, 2024 13:28 Back to list

OEM Flat Keder Edge PVC Welt Strip for Custom Upholstery and Trailers

Understanding OEM Flat Keder Edge PVC Welt Strip A Comprehensive Overview

The world of manufacturing and design is often driven by the need for specialized components that enhance functionality, aesthetics, and overall product durability. One such vital component is the OEM (Original Equipment Manufacturer) flat keder edge PVC welt strip. This article explores its significance, applications, and benefits, drawing attention to why this seemingly simple strip deserves a closer look.

What is a Keder Strip?

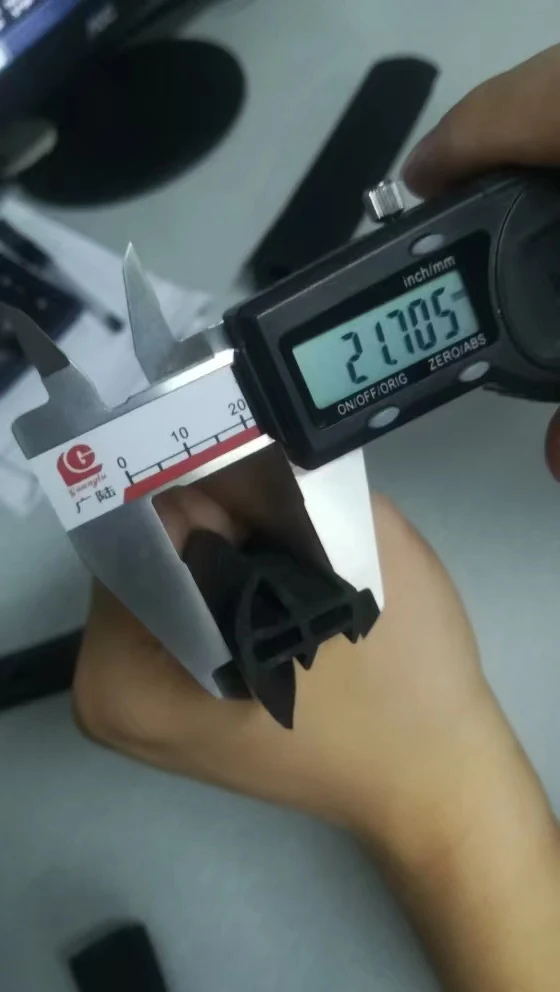

A keder strip is a type of fabric or material that is typically used to provide a clean, finished edge to various products. It is often seen in tents, awnings, and other outdoor applications where robustness is essential. The term keder itself refers to the cord sewn into the strip, allowing for easy insertion into channels or tracks. The flat keder edge PVC welt strip, specifically, features a flat design that enhances its versatility and ease of use.

Material Composition

As the name suggests, the keder strip is made from PVC (Polyvinyl Chloride), a widely used synthetic plastic polymer. PVC is renowned for its durability, weather resistance, and flexibility, making it an ideal choice for outdoor applications. The use of PVC in keder strips ensures that they can withstand various environmental conditions, including UV exposure, rain, and wind, making them suitable for a range of outdoor products.

Applications of Flat Keder Edge PVC Welt Strip

The applications of OEM flat keder edge PVC welt strips are vast and varied, spanning several industries

1. Camping and Outdoor Equipment These strips are commonly used in tents and canopies. The keder edge allows for a tight and secure fit, ensuring that the structure remains stable and weather-resistant.

2. Tarpaulins and Covers Tarpaulins often incorporate keder strips for reinforcing edges, enhancing durability, and providing secure attachment points.

oem flat keder edge pvc welt strip

4. Furniture Some outdoor furniture uses PVC welt strips in their design, contributing to aesthetic appeal while protecting edges from wear.

5. Inflatable Products Inflatable items, such as pontoons or air mattresses, often use keder strips for connection points and seams, ensuring leak-proof designs.

Benefits of Using OEM Flat Keder Edge PVC Welt Strips

1. Durability The PVC material is exceptionally durable, resisting tearing and wear, which is crucial for products exposed to the elements.

2. Flexibility The flat design provides easy handling and versatility in various applications. It can easily conform to different shapes and sizes.

3. Aesthetic Appeal With its clean finish, the keder strip enhances the visual appeal of products, providing a professional look while serving its functional purpose.

4. Customization Being an OEM product, these strips can be tailored to meet specific requirements. Manufacturers can request custom sizes, colors, and designs to match their products perfectly.

5. Ease of Application The keder strip simplifies the installation process. Its design allows for quick insertion into tracks or channels, saving time in production.

Conclusion

The OEM flat keder edge PVC welt strip may appear to be a minor component, but its role in enhancing product performance cannot be underestimated. From outdoor equipment to marine applications, its versatility and durability make it a favorite among manufacturers. As industries continue to evolve and adapt to new challenges, the relevance of such specialized components will only grow, showcasing the necessity of investing in quality materials like the keder edge PVC welt strip. By understanding its significance, businesses can make informed decisions that improve both functionality and consumer satisfaction in their products.

-

Top LED Neon Rope Light Outdoor Companies – Durable & Weatherproof Solutions

NewsJul.23,2025

-

Top Window Seal Strip Adhesive Companies for Quality Sealing Solutions

NewsJul.22,2025

-

HighTech Injection LED Module Size 6414 - Efficient, Durable Lighting

NewsJul.22,2025

-

Top Window Seal Strip Adhesive Companies | Durable Weatherproof Seals

NewsJul.21,2025

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025