Top Companies in PVC Extrusion Profile Manufacturing and Supply

កញ្ញា . 23, 2024 11:08 Back to list

Top Companies in PVC Extrusion Profile Manufacturing and Supply

The Landscape of PVC Extrusion Profile Companies

Polyvinyl Chloride (PVC) is one of the most widely used plastic materials in the world. Its versatility, durability, and cost-effectiveness make it an ideal choice for a variety of applications, including construction, automotive, and consumer goods. PVC extrusion profiles, specifically, are a critical segment of the industry. This article will explore the landscape of PVC extrusion profile companies, their significance, and the trends shaping the industry.

Understanding PVC Extrusion Profiles

PVC extrusion involves melting PVC pellets and forcing them through a shaped die to create continuous lengths of profiles in various shapes. These profiles can be used for windows, doors, plumbing, wiring insulation, and more. The process allows for the production of complex shapes and sizes tailored to specific applications, providing flexibility for manufacturers and consumers alike.

The Role of PVC Extrusion Profile Companies

PVC extrusion profile companies are key players in the supply chain. They not only manufacture but also innovate and improve existing designs to meet market demands. Through advanced extrusion technology, these companies strive to enhance product performance and accessibility while maintaining sustainability and compliance with industry standards.

Market Dynamics and Key Players

The PVC extrusion profile market is populated by several key players, ranging from large multinational corporations to specialized local manufacturers. Notable companies such as Deceuninck, Rehau, and VEKA have established themselves as leaders due to their commitment to quality and innovative solutions. These companies invest heavily in research and development to stay ahead of the competition and offer unique products that cater to evolving consumer needs.

In addition to established players, the industry also includes numerous smaller firms that bring niche products and flexibility to the market. These smaller companies often focus on specific applications or regional markets, allowing them to compete effectively with larger firms.

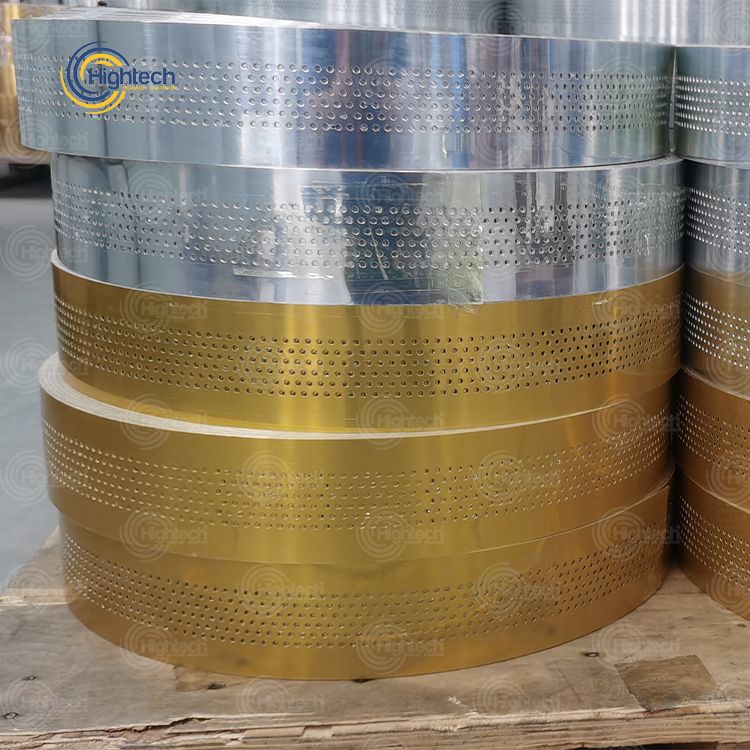

pvc extrusion profile companies

Trends Influencing the Industry

1. Sustainability The global push toward sustainability is influencing how PVC extrusion profile companies operate. Manufacturers are increasingly adopting recycled PVC and developing processes that minimize waste. Many companies are also pursuing certifications that highlight their commitment to environmental responsibility, responding to consumer demand for greener products.

2. Technological Advancements Advanced technologies, such as co-extrusion and 3D printing, are reshaping the PVC profile landscape. Co-extrusion allows for the production of profiles with multiple layers, enhancing performance attributes such as insulation and durability. Meanwhile, 3D printing technology is enabling more complex designs and faster prototyping, facilitating customization in a way that was previously unfeasible.

3. Regulatory Compliance Companies in the PVC extrusion profile sector must navigate a complex web of regulations regarding product safety and environmental impact. Maintaining compliance with these regulations is crucial, as non-compliance can lead to significant penalties and reputational damage.

4. Market Demand The demand for energy-efficient building materials has surged as consumers become more environmentally conscious. PVC profiles, which are often used in window and door manufacturing, can significantly enhance the energy efficiency of buildings. This growing demand has encouraged manufacturers to focus on high-performance products that meet or exceed energy standards.

Conclusion

As the world continues to evolve, so too does the landscape for PVC extrusion profile companies. These firms play a pivotal role in providing a diverse array of products that cater to the needs of various industries. By embracing sustainability, investing in technology, and adhering to regulatory standards, PVC extrusion profile companies are positioned to thrive in an increasingly competitive market.

The future of this industry appears promising, with opportunities for growth and innovation around every corner. Understanding the dynamics of this sector will be essential for stakeholders looking to navigate the challenges and leverage the opportunities that lie ahead. As these companies continue to adapt to changing market conditions, they will remain integral to the development of versatile, high-quality PVC solutions.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025