vinyl strip and seal manufacturer

វិច្ឆិកា . 05, 2024 04:43 Back to list

vinyl strip and seal manufacturer

The Role of Vinyl Strip and Seal Manufacturers in Modern Industry

In today's fast-paced industrial landscape, maintaining cleanliness and minimizing contamination are paramount concerns for businesses across various sectors. From food processing to pharmaceuticals, the integrity of environments is critical. One of the key players in ensuring these standards are met is the vinyl strip and seal manufacturer. These manufacturers produce essential products that help businesses maintain optimal conditions while also enhancing overall operational efficiency.

Understanding Vinyl Strips and Seals

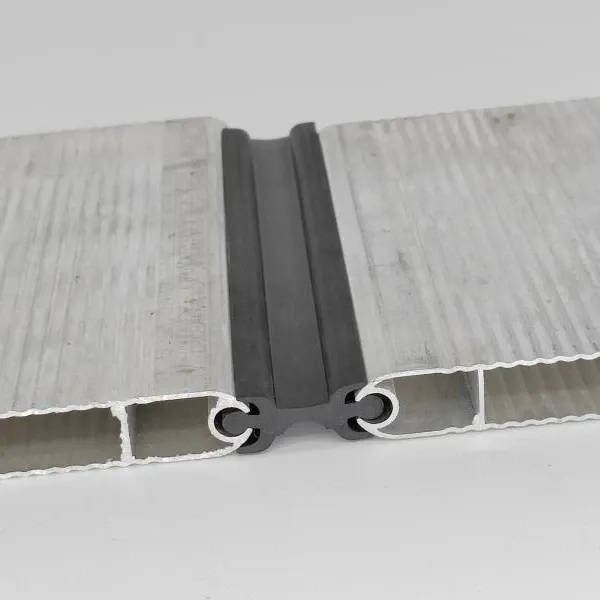

Vinyl strips and seals are flexible barriers made from durable vinyl materials designed to separate different areas within a facility. They serve multiple purposes, including temperature regulation, noise reduction, and contamination prevention. These products are particularly prevalent in industries that require strict adherence to hygiene and safety standards.

The versatility of vinyl strips allows them to be used in various applications. For example, in food processing plants, they can prevent cross-contamination by creating physical barriers between raw and cooked foods. In warehouses, they can help in separating climate-controlled areas from non-climate-controlled spaces, thereby preserving the integrity of sensitive products.

Customization and Innovation

One of the strengths of vinyl strip and seal manufacturers is their ability to offer customized solutions tailored to specific industry needs. Manufacturers often work closely with their clients to understand the unique challenges they face. As a result, they create bespoke products that address particular conditions, such as varying temperatures, humidity levels, or product types.

Innovation plays a crucial role in the vinyl strip and seal industry. Manufacturers continuously invest in research and development to improve the quality, durability, and effectiveness of their products. For instance, advancements in material technology have led to the production of vinyl strips with enhanced resistance to UV light, chemicals, and extreme temperatures. This innovation not only extends the life of the product but also ensures that it meets the evolving standards of various industries.

Environmental Considerations

As businesses become increasingly aware of their environmental impact, vinyl strip and seal manufacturers are also adapting to meet sustainability goals. Many manufacturers are exploring eco-friendly materials and processes to reduce their carbon footprint. For example, some are developing recyclable or biodegradable vinyl products, while others focus on minimizing waste during the manufacturing process.

vinyl strip and seal manufacturer

By adopting sustainable practices, vinyl strip and seal manufacturers not only contribute to environmental conservation but also help their clients meet their sustainability targets. This synergy is becoming vital as consumers and regulatory bodies press for greater corporate responsibility.

The Economic Impact

The role of vinyl strip and seal manufacturers extends beyond just product provision; they also contribute significantly to the economy. By supporting various industries, these manufacturers create job opportunities, stimulate local economies, and foster innovation. Their work ensures that businesses can operate smoothly, reducing operational downtime and enhancing productivity.

Moreover, with the rise of e-commerce and global trade, the demand for efficient shipping solutions has skyrocketed. Vinyl strips and seals can help optimize shipping processes by maintaining appropriate conditions for sensitive goods during transit, thereby ensuring quality and safety. This demand not only boosts the manufacturing sector but also reinforces supply chain logistics.

Future Trends

As we look toward the future, the vinyl strip and seal manufacturing industry will likely continue to evolve alongside technological advancements and industry needs. The integration of smart technologies, such as IoT sensors that monitor environmental conditions in real-time, could revolutionize how these products are used and maintained.

Furthermore, as industries focus on automation and efficiency, vinyl strip and seal manufacturers will need to adapt their offerings to align with these trends. This may include developing products that seamlessly integrate with automated systems, ensuring that they provide the necessary separation and protection without hindering operational workflows.

Conclusion

In conclusion, vinyl strip and seal manufacturers play a critical role in modern industry by providing essential products that enhance safety, efficiency, and sustainability. Their ability to innovate and customize solutions ensures that businesses can meet their specific needs while contributing to the overall economy. As industries continue to evolve, so too will the role of these manufacturers, making them indispensable partners in the quest for operational excellence.

-

Air Filter Replacement Core for K-archer WD4.200 WD5.200 WD4 WD5

NewsJul.28,2025

-

Top Window Seal Strip Adhesive Companies for Durable Solutions

NewsJul.27,2025

-

Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter

NewsJul.26,2025

-

Factory Hot Sale Recycled Green Elastic Profiles Wholesale Supplier

NewsJul.25,2025

-

Hi flo Oil Filter H F155 for KT M 250 EXC Racing 2003-2006, OEM Quality

NewsJul.24,2025

-

Top LED Neon Rope Light Outdoor Companies – Durable & Weatherproof Solutions

NewsJul.23,2025