LED Flexible Neon Strip Light Manufacturing Companies and Their Key Offerings

ಡಿಸೆ . 16, 2024 15:18 Back to list

LED Flexible Neon Strip Light Manufacturing Companies and Their Key Offerings

The Rise of LED Flexible Neon Strip Light Factories

In recent years, the demand for innovative lighting solutions has surged, and one of the most exciting advancements in this area is the development of LED flexible neon strip lights. These lights not only offer vibrant colors and design flexibility but also promise energy efficiency and longevity. As a result, the emergence of LED flexible neon strip light factories has significantly transformed the lighting industry.

Understanding LED Flexible Neon Strip Lights

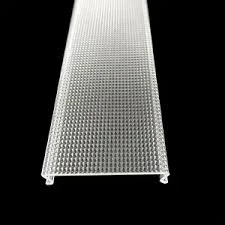

LED flexible neon strip lights are characterized by their unique construction that includes silicone or PVC encasings filled with LED lights. Unlike traditional neon lights, which are made from glass and require high voltage to operate, LED neon strips are much more versatile. They can easily bend and conform to various shapes, making them ideal for creative lighting applications in residential, commercial, and industrial settings.

One of the key advantages of LED flexible neon strip lights is their energy efficiency. Consuming significantly less power than traditional neon lights, these LED alternatives can drastically reduce electricity bills while still providing bright illumination. Moreover, their lifespan can reach up to 50,000 hours or more, which is a considerable improvement over conventional lighting options.

The Role of Factories in Production

The establishment of LED flexible neon strip light factories has been pivotal in meeting the growing demand for these lighting solutions. These factories employ advanced manufacturing techniques and technologies to produce high-quality products efficiently. With the ability to customize shapes, colors, and lengths of neon strips, manufacturers are able to cater to a wide range of consumer preferences. From vibrant hues to subtle pastels, the variations available allow designers more freedom to create unique environments.

In addition to customization, the factories often invest in automated processes to enhance production efficiency. Automation not only speeds up the manufacturing process but also ensures consistent quality across all products. This is essential for maintaining brand reputation and customer satisfaction, particularly in an industry where the aesthetics of lighting play a crucial role.

led flexible neon strip light factories

Challenges in the Manufacturing Process

While the growth of LED flexible neon strip light factories opens up exciting opportunities, it also presents several challenges. One issue facing manufacturers is the sourcing of high-quality materials. The quality of silicone or PVC used in the LED encasing can significantly impact the durability and performance of the final product. Ensuring a steady supply of these materials at competitive prices is essential for success.

Moreover, competition within the market is fierce. With many players entering the industry, factories must find ways to differentiate themselves. This can be achieved through innovative design, superior quality control, or enhanced customer service. Investing in research and development is crucial for creating cutting-edge products that can stand out in a crowded marketplace.

The Future of LED Flexible Neon Strip Lights

Looking ahead, the future of LED flexible neon strip light factories appears bright. As trends in interior and exterior design continue to evolve, the flexibility and variety offered by these lights will play an increasingly important role. From residential homes looking to add a touch of whimsy to commercial establishments aiming for a bold statement, the potential applications are limitless.

Furthermore, as sustainability becomes a focal point in manufacturing practices, LED lights inherently align with these values. Their energy efficiency and long lifespan contribute to reducing the overall carbon footprint associated with lighting. Factories that prioritize eco-friendly practices will not only appeal to environmentally conscious consumers but may also benefit from government incentives aimed at promoting sustainable manufacturing.

Conclusion

In summary, the rise of LED flexible neon strip light factories marks a significant shift in the lighting industry. With their ability to offer customization, energy efficiency, and an extensive range of applications, these lights are fast becoming a preferred choice for designers and consumers alike. As technology advances and manufacturers adapt to the challenges of production, the possibilities for LED flexible neon strip lights are endless. Embracing creativity and sustainability, this sector is poised for continued growth and innovation in the coming years.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025