Understanding the Process and Benefits of PVC Extrusion Profiles in China’s Manufacturing Industry

ಆಗಸ್ಟ್ . 06, 2024 15:08 Back to list

Understanding the Process and Benefits of PVC Extrusion Profiles in China’s Manufacturing Industry

Understanding PVC Extrusion Profiles in China

PVC (Polyvinyl Chloride) has become one of the most widely used materials in various industries due to its versatility, durability, and cost-effectiveness. In China, PVC extrusion profiles have gained significant traction, contributing to the country's robust manufacturing sector. This article explores the key aspects of PVC extrusion profiles, highlighting their applications, manufacturing processes, and the competitive landscape in China.

What are PVC Extrusion Profiles?

PVC extrusion profiles are shapes produced by forcing heated PVC material through a die to create continuous lengths of material with a fixed cross-sectional profile. These profiles can be found in a myriad of applications, including windows, doors, trims, and various construction components. The flexibility of PVC allows for an extensive range of designs and colors, making it an attractive option for architects and designers.

Applications of PVC Extrusion Profiles

The applications of PVC extrusion profiles in China are diverse and reflect the country's rapid urbanization and development. One of the most common applications is in the construction sector, where PVC profiles are used for window frames, door frames, and decorative moldings. These products are favored for their resistance to moisture, UV light, and chemicals, ensuring longevity and minimal maintenance.

In addition to construction, PVC profiles are increasingly utilized in furniture manufacturing, automotive parts, and electrical enclosures. The non-toxic nature of PVC makes it an ideal choice for items used in household environments and children's products. Moreover, in the electrical industry, PVC extrusion profiles provide insulation and protection for wiring, enhancing safety.

The Manufacturing Process

The manufacturing of PVC extrusion profiles in China involves several key steps. First, raw PVC material is selected and mixed with additives to enhance its properties, such as flexibility, color, and resistance to fire or UV light. This mixture is then heated and fed into an extruder, where it's melted and pushed through a die to form the desired shape.

china pvc extrusion profile

Once the profile emerges from the die, it is cooled and solidified, usually by passing through a water bath or air cooling system. After solidification, the profiles are cut to length and may undergo additional processes such as surface treatment or coating to improve their aesthetics and functionality.

Quality control is a critical aspect of the manufacturing process. Chinese manufacturers often employ advanced technologies and strict quality assurance measures to ensure that the final products meet international standards.

Competitive Landscape

China is one of the largest producers of PVC profiles in the world. The competitive landscape is characterized by a mix of large-scale manufacturers and smaller enterprises, providing a wide range of products to various markets. The rise of China as a manufacturing hub has led to increased investment in technology and innovation within the PVC extrusion industry.

Key players in this sector are continuously striving to improve their production efficiency while maintaining product quality. They are also focusing on environmentally-friendly practices, developing recycled PVC products as sustainability becomes increasingly important.

Additionally, the demand for customized profiles is on the rise, pushing manufacturers to invest in flexible production processes that can accommodate unique designs and specifications.

Conclusion

The PVC extrusion profile market in China is a dynamic segment of the broader materials industry. With its extensive applications across various sectors, coupled with advancements in manufacturing technologies, the future of PVC profiles looks promising. As sustainability becomes a more pressing concern globally, the industry is likely to adapt and innovate, ensuring that PVC remains a viable and environmentally-conscious choice in construction and beyond. As China continues to grow its manufacturing capabilities, the PVC extrusion profile sector will undoubtedly play a crucial role in the country's economic development.

-

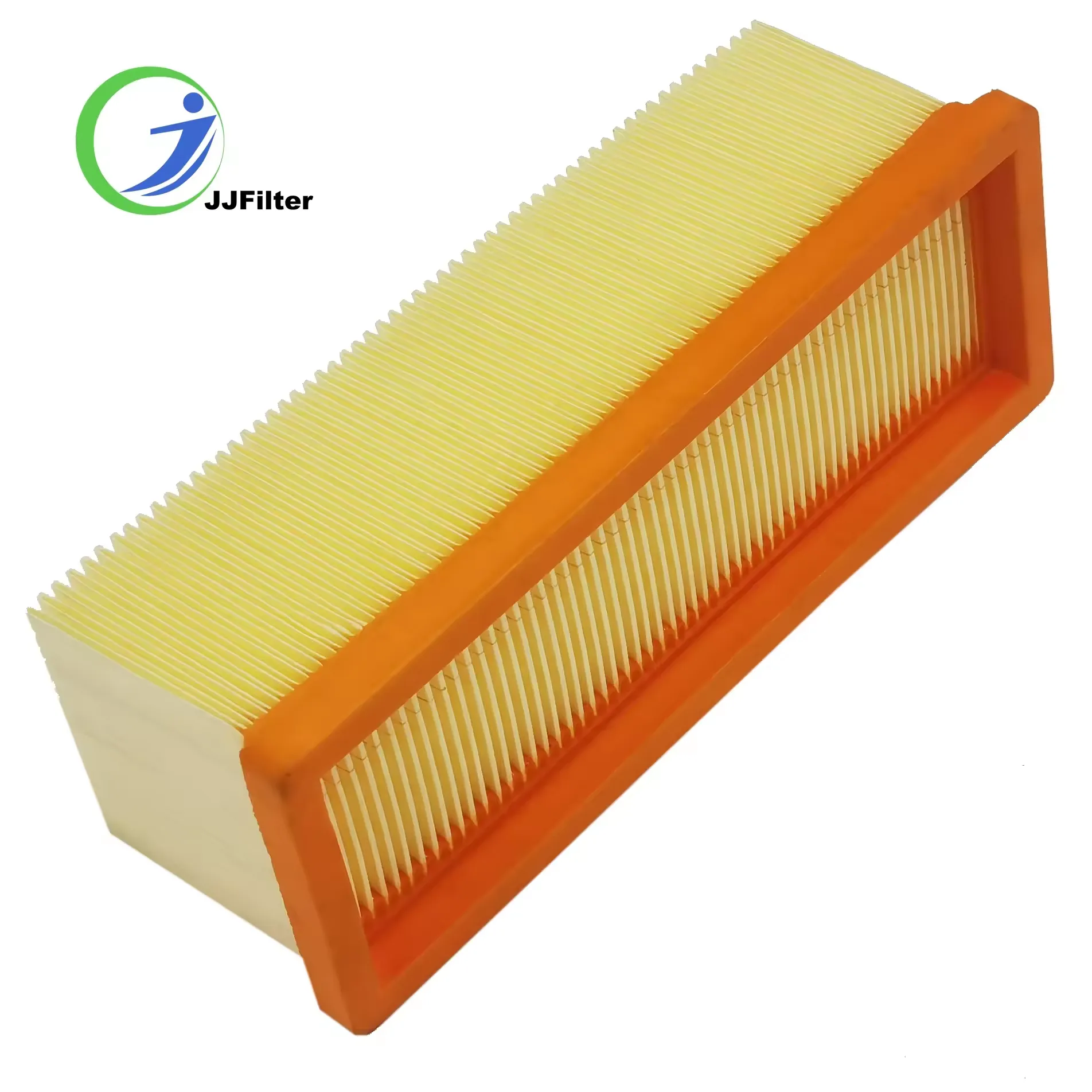

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025

-

Factory Hot Sale Thin Silicone Sewn Strip Roll Wholesale, Durable & Flexible

NewsJul.30,2025