Top Manufacturers of Silicone Sponge Seals for Various Applications

تشرینی دووەم . 26, 2024 07:01 Back to list

Top Manufacturers of Silicone Sponge Seals for Various Applications

Silicone Sponge Seal Manufacturers An Essential Component of Modern Manufacturing

In the manufacturing industry, the importance of seals cannot be overstated. They are crucial components that ensure the integrity and functionality of various products across different sectors. Among the various materials used for sealing solutions, silicone sponge has garnered significant attention due to its exceptional properties. This article explores the role of silicone sponge seal manufacturers in modern manufacturing and the advantages of silicone sponge seals.

Understanding Silicone Sponge Seals

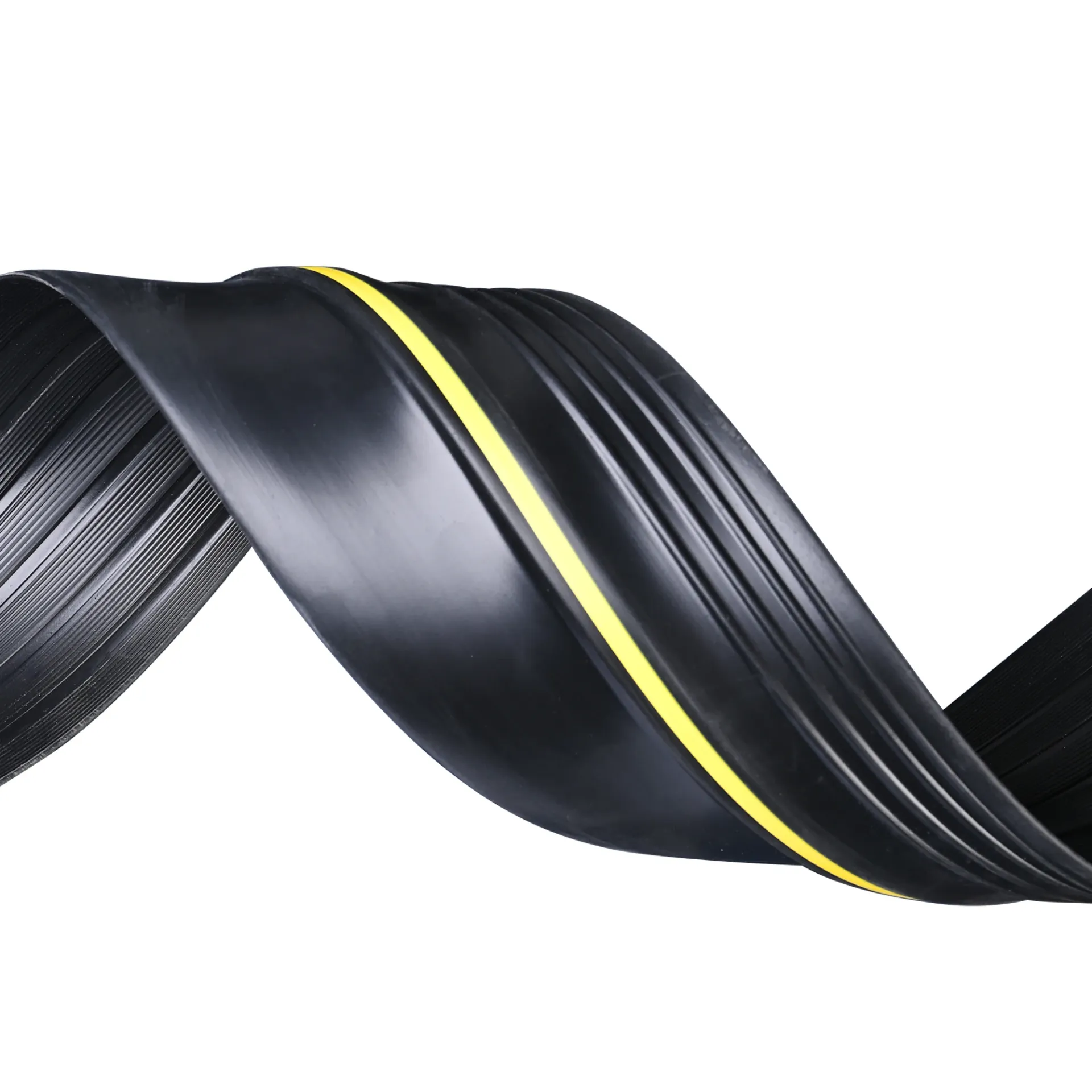

Silicone sponge seals are made from a unique blend of silicone rubber and air-filled sponge material. This combination results in a lightweight, flexible, and resilient sealing solution that can withstand a wide range of environmental conditions. These seals are known for their excellent temperature resistance, compressibility, and durability, making them suitable for various applications, including automotive, aerospace, electronics, and household items.

The Importance of Manufacturers

Silicone sponge seal manufacturers play a pivotal role in ensuring the availability and quality of these seals. They are responsible for the design, production, and distribution of silicone sponge seals that meet industry standards and customer specifications. Manufacturers invest in advanced machinery and skilled labor to produce high-quality seals that can withstand various pressures and temperatures. They also prioritize research and development to innovate and improve their products continually.

Key Advantages of Silicone Sponge Seals

1. Temperature Resistance One of the most significant advantages of silicone sponge seals is their ability to withstand extreme temperatures, ranging from -60°C to +200°C. This makes them ideal for applications in automotive engines and electronic devices where varying temperatures could compromise the integrity of traditional seals.

2. Chemical Stability Silicone is inherently resistant to many chemicals, oils, and solvents, providing additional protection in environments where exposure to harsh substances is a concern. This quality makes silicone sponge seals suitable for use in the food and pharmaceutical industries, where cleanliness and purity are paramount.

silicone sponge seal manufacturer

3. Flexibility and Compression Set Silicone sponge seals are highly compressible, allowing them to create a tight seal even when faced with uneven surfaces. Their flexibility ensures that they can adapt to different shapes and sizes, making them versatile for various applications.

4. Lightweight Nature The lightweight nature of silicone sponge seals reduces the overall weight of the products they are used in, which is particularly advantageous in automotive and aerospace applications where weight reduction is critical for efficiency and performance.

5. Durability Silicone sponge seals exhibit excellent aging properties, resisting degradation over time. This longevity translates into reduced maintenance costs and extended product life cycles, which are beneficial for manufacturers and consumers alike.

The Future of Silicone Sponge Seal Manufacturing

As industries continue to evolve, the demand for high-quality sealing solutions will likely grow. Manufacturers of silicone sponge seals must stay attuned to market trends and technological advancements to remain competitive. Innovations in material science and manufacturing techniques will allow them to develop even more efficient and effective seals that cater to specific needs, such as higher pressures or specialized environments.

Sustainability is also becoming increasingly important in manufacturing. Many manufacturers are exploring eco-friendly materials and production processes to reduce their environmental impact. As consumers become more environmentally conscious, companies that prioritize sustainability will likely gain a competitive edge in the market.

Conclusion

Silicone sponge seal manufacturers are critical players in the manufacturing landscape, providing essential components that enhance product performance and durability. With their unique properties and advantages, silicone sponge seals have proven to be an invaluable choice across various industries. As technology advances and sustainability becomes a priority, these manufacturers will be well-positioned to meet the evolving demands of the marketplace while paving the way for a more efficient and environmentally friendly future.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025