0.8% polycarbonate plastic diffuser factories

Jun . 16, 2024 14:17 Back to list

0.8% polycarbonate plastic diffuser factories

The Evolution and Impact of 0.8% Thick Polycarbonate Plastic Diffuser in Manufacturing

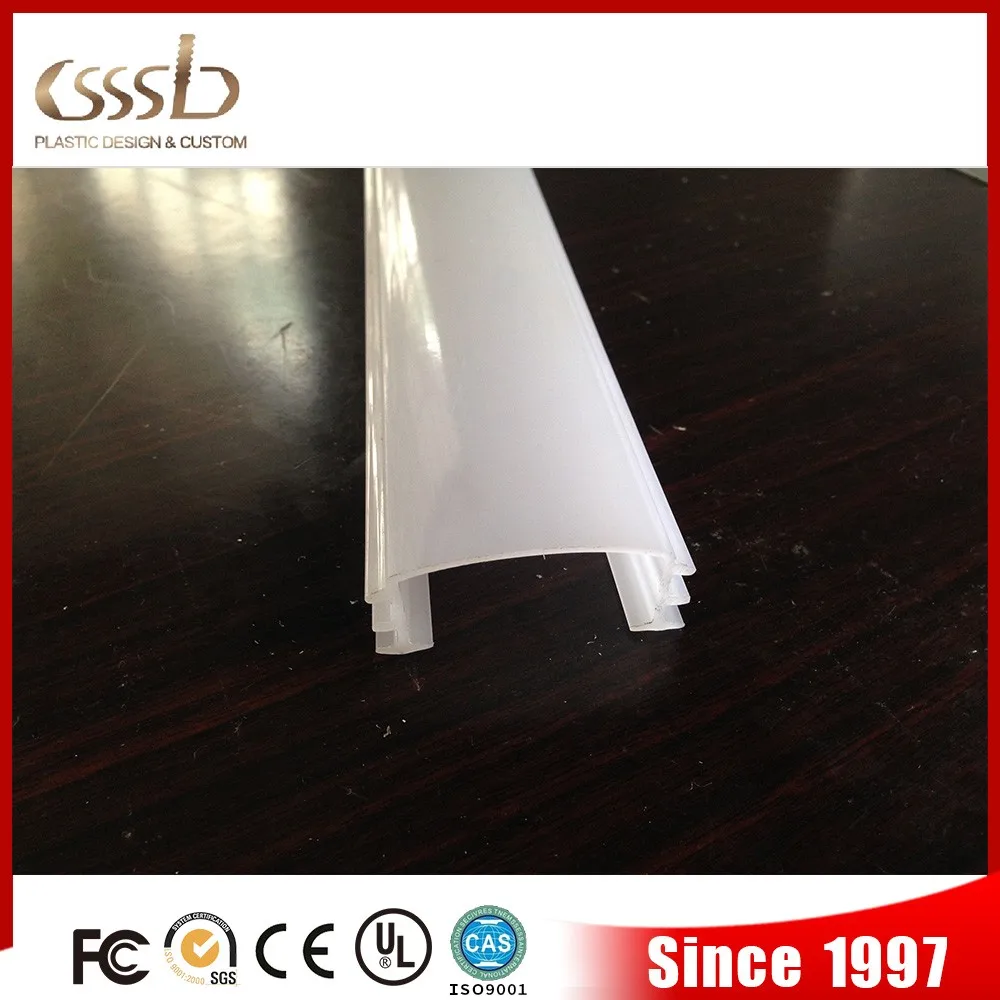

In the realm of industrial manufacturing, the emergence of a seemingly minor detail like the 0.8% thick polycarbonate plastic diffuser has significantly impacted various sectors. This specialized material, known for its lightweight yet durable nature, has become an essential component in factories worldwide.

Polycarbonate plastic, with its exceptional clarity and high impact resistance, serves as an ideal choice for diffusers. These diffusers are designed to scatter light evenly, reducing glare and improving illumination efficiency. The thickness of 0.8% is meticulously calculated to ensure optimal performance without compromising on the strength and longevity of the material.

Factories producing these polycarbonate diffusers have seen a surge in demand across industries such as lighting, automotive, and architectural design. The automotive industry, in particular, has integrated these diffusers into headlights and tail lights, enhancing both aesthetics and functionality. Similarly, architects leverage this material to create visually stunning and energy-efficient building facades that manipulate natural light.

The production process of these diffusers is a testament to precision engineering

The production process of these diffusers is a testament to precision engineering The production process of these diffusers is a testament to precision engineering

The production process of these diffusers is a testament to precision engineering

The production process of these diffusers is a testament to precision engineering

The production process of these diffusers is a testament to precision engineering 0.8 thick polycarbonate plastic diffuser factories. It begins with the molding of the polycarbonate sheets, which are then cut and polished to achieve the desired thickness and smoothness. The surface is often treated with special coatings to enhance its light scattering properties or to imbue it with additional functionalities like UV resistance or heat dissipation.

As technology continues to evolve, so too does the application of 0.8% thick polycarbonate plastic diffusers. Innovations in printing and nanotechnology have allowed manufacturers to incorporate intricate patterns and photonic crystals onto the diffuser surfaces, opening up new avenues for light manipulation and energy savings.

Moreover, the eco-friendly nature of polycarbonate plastic makes it a sustainable choice for manufacturers committed to reducing environmental footprints. Recycling processes for this material are well-established, contributing to a closed-loop manufacturing cycle that minimizes waste.

In conclusion, the humble 0.8% thick polycarbonate plastic diffuser has transcended its functional purpose to become a cornerstone of innovation in factory production lines. Its journey from a simple lighting accessory to a multifaceted industrial commodity underscores the broader trend of materials science shaping the future of manufacturing and design.

0.8 thick polycarbonate plastic diffuser factories. It begins with the molding of the polycarbonate sheets, which are then cut and polished to achieve the desired thickness and smoothness. The surface is often treated with special coatings to enhance its light scattering properties or to imbue it with additional functionalities like UV resistance or heat dissipation.

As technology continues to evolve, so too does the application of 0.8% thick polycarbonate plastic diffusers. Innovations in printing and nanotechnology have allowed manufacturers to incorporate intricate patterns and photonic crystals onto the diffuser surfaces, opening up new avenues for light manipulation and energy savings.

Moreover, the eco-friendly nature of polycarbonate plastic makes it a sustainable choice for manufacturers committed to reducing environmental footprints. Recycling processes for this material are well-established, contributing to a closed-loop manufacturing cycle that minimizes waste.

In conclusion, the humble 0.8% thick polycarbonate plastic diffuser has transcended its functional purpose to become a cornerstone of innovation in factory production lines. Its journey from a simple lighting accessory to a multifaceted industrial commodity underscores the broader trend of materials science shaping the future of manufacturing and design.

The production process of these diffusers is a testament to precision engineering

The production process of these diffusers is a testament to precision engineering

The production process of these diffusers is a testament to precision engineering

The production process of these diffusers is a testament to precision engineering 0.8 thick polycarbonate plastic diffuser factories. It begins with the molding of the polycarbonate sheets, which are then cut and polished to achieve the desired thickness and smoothness. The surface is often treated with special coatings to enhance its light scattering properties or to imbue it with additional functionalities like UV resistance or heat dissipation.

As technology continues to evolve, so too does the application of 0.8% thick polycarbonate plastic diffusers. Innovations in printing and nanotechnology have allowed manufacturers to incorporate intricate patterns and photonic crystals onto the diffuser surfaces, opening up new avenues for light manipulation and energy savings.

Moreover, the eco-friendly nature of polycarbonate plastic makes it a sustainable choice for manufacturers committed to reducing environmental footprints. Recycling processes for this material are well-established, contributing to a closed-loop manufacturing cycle that minimizes waste.

In conclusion, the humble 0.8% thick polycarbonate plastic diffuser has transcended its functional purpose to become a cornerstone of innovation in factory production lines. Its journey from a simple lighting accessory to a multifaceted industrial commodity underscores the broader trend of materials science shaping the future of manufacturing and design.

0.8 thick polycarbonate plastic diffuser factories. It begins with the molding of the polycarbonate sheets, which are then cut and polished to achieve the desired thickness and smoothness. The surface is often treated with special coatings to enhance its light scattering properties or to imbue it with additional functionalities like UV resistance or heat dissipation.

As technology continues to evolve, so too does the application of 0.8% thick polycarbonate plastic diffusers. Innovations in printing and nanotechnology have allowed manufacturers to incorporate intricate patterns and photonic crystals onto the diffuser surfaces, opening up new avenues for light manipulation and energy savings.

Moreover, the eco-friendly nature of polycarbonate plastic makes it a sustainable choice for manufacturers committed to reducing environmental footprints. Recycling processes for this material are well-established, contributing to a closed-loop manufacturing cycle that minimizes waste.

In conclusion, the humble 0.8% thick polycarbonate plastic diffuser has transcended its functional purpose to become a cornerstone of innovation in factory production lines. Its journey from a simple lighting accessory to a multifaceted industrial commodity underscores the broader trend of materials science shaping the future of manufacturing and design. Latest news

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025

-

Factory Hot Sale Thin Silicone Sewn Strip Roll Wholesale, Durable & Flexible

NewsJul.30,2025