single edge aluminum strips

Jan . 16, 2025 03:32 Back to list

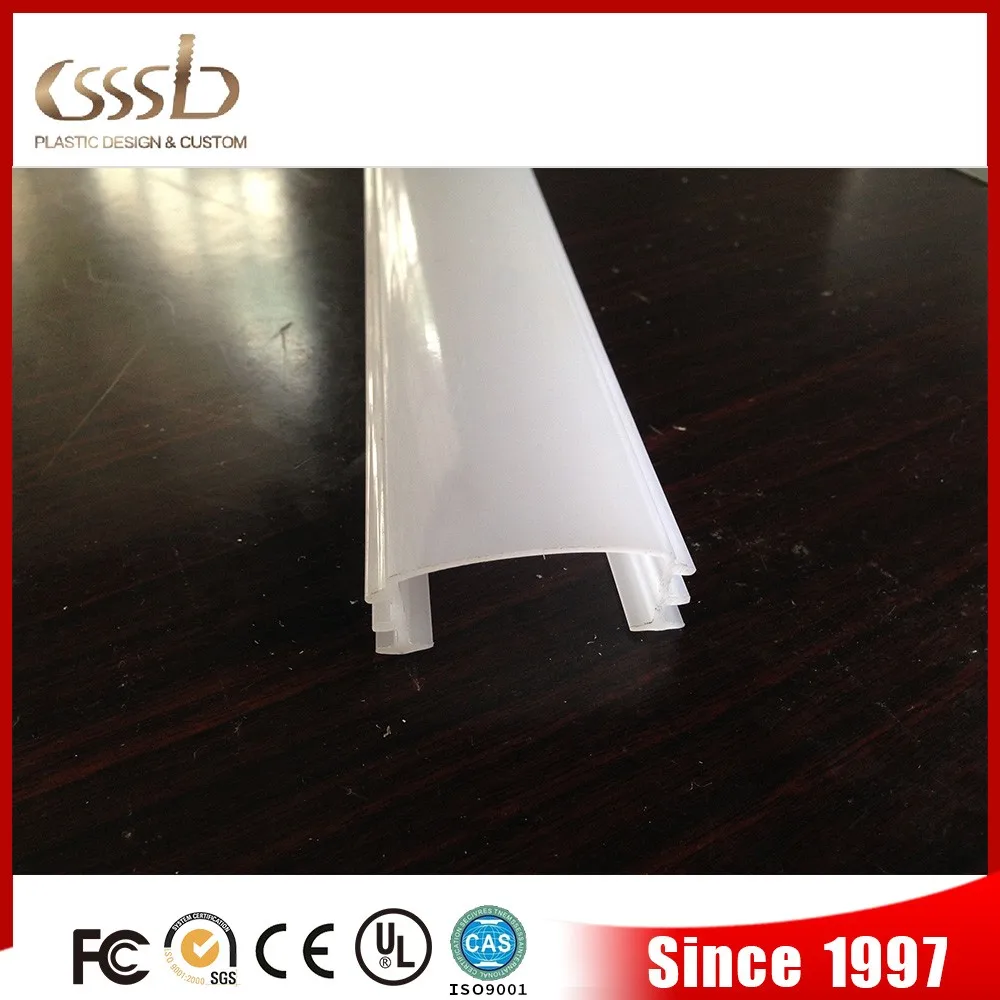

single edge aluminum strips

Single edge aluminum strips have become an indispensable component in various industries due to their unique properties and versatility. Derived from high-quality aluminum, these strips are engineered for efficiency and performance in multiple applications, providing solutions where precision and durability are paramount.

Electronics manufacturers also take advantage of single edge aluminum strips for their thermal and electrical conductivity properties. They are integral in the production of various electronic components, including heat sinks and capacitors, which are crucial for managing device temperatures and ensuring efficient operation. By utilizing these strips, manufacturers can significantly enhance the performance and lifespan of electronic products. The expertise involved in the production of single edge aluminum strips is critical. Manufacturers must maintain stringent quality control measures and employ advanced technologies to produce strips that meet industry standards. This includes precision cutting and treatment processes that ensure each strip is uniform in thickness and possesses superior edge quality, which is essential for applications requiring high accuracy and consistency. Trustworthiness is an essential factor when sourcing single edge aluminum strips. Collaborating with reputable suppliers who adhere to international quality standards and regulations ensures that the strips will perform as intended in their respective applications. Certification and traceability of materials are vital, providing assurance and accountability in an often-demanding market. In conclusion, the integration of single edge aluminum strips across various sectors showcases their indispensable role due to their multifaceted properties. As industries continue to evolve, the reliance on these strips is expected to grow, driven by ongoing advancements and innovations in material science. Their contribution not only enhances product performance and efficiency but also champions sustainability through recyclability and reduced energy consumption, solidifying their status as a vital component in modern manufacturing and engineering spheres.

Electronics manufacturers also take advantage of single edge aluminum strips for their thermal and electrical conductivity properties. They are integral in the production of various electronic components, including heat sinks and capacitors, which are crucial for managing device temperatures and ensuring efficient operation. By utilizing these strips, manufacturers can significantly enhance the performance and lifespan of electronic products. The expertise involved in the production of single edge aluminum strips is critical. Manufacturers must maintain stringent quality control measures and employ advanced technologies to produce strips that meet industry standards. This includes precision cutting and treatment processes that ensure each strip is uniform in thickness and possesses superior edge quality, which is essential for applications requiring high accuracy and consistency. Trustworthiness is an essential factor when sourcing single edge aluminum strips. Collaborating with reputable suppliers who adhere to international quality standards and regulations ensures that the strips will perform as intended in their respective applications. Certification and traceability of materials are vital, providing assurance and accountability in an often-demanding market. In conclusion, the integration of single edge aluminum strips across various sectors showcases their indispensable role due to their multifaceted properties. As industries continue to evolve, the reliance on these strips is expected to grow, driven by ongoing advancements and innovations in material science. Their contribution not only enhances product performance and efficiency but also champions sustainability through recyclability and reduced energy consumption, solidifying their status as a vital component in modern manufacturing and engineering spheres.

Latest news

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025