Top Quality U-Shaped Plastic Profiles from C Channel Extrusion Experts

Sep . 30, 2024 16:13 Back to list

Top Quality U-Shaped Plastic Profiles from C Channel Extrusion Experts

Best C Channel Plastic Extrusion U-Shaped Plastic Profiles

Plastic extrusion has become an essential manufacturing process in various industries, and among its many applications, U-shaped plastic profiles are particularly noteworthy. When discussing the best C channel plastic extrusion, it’s important to understand what makes these products desirable, along with their applications and benefits.

Understanding U-Shaped Plastic Profiles

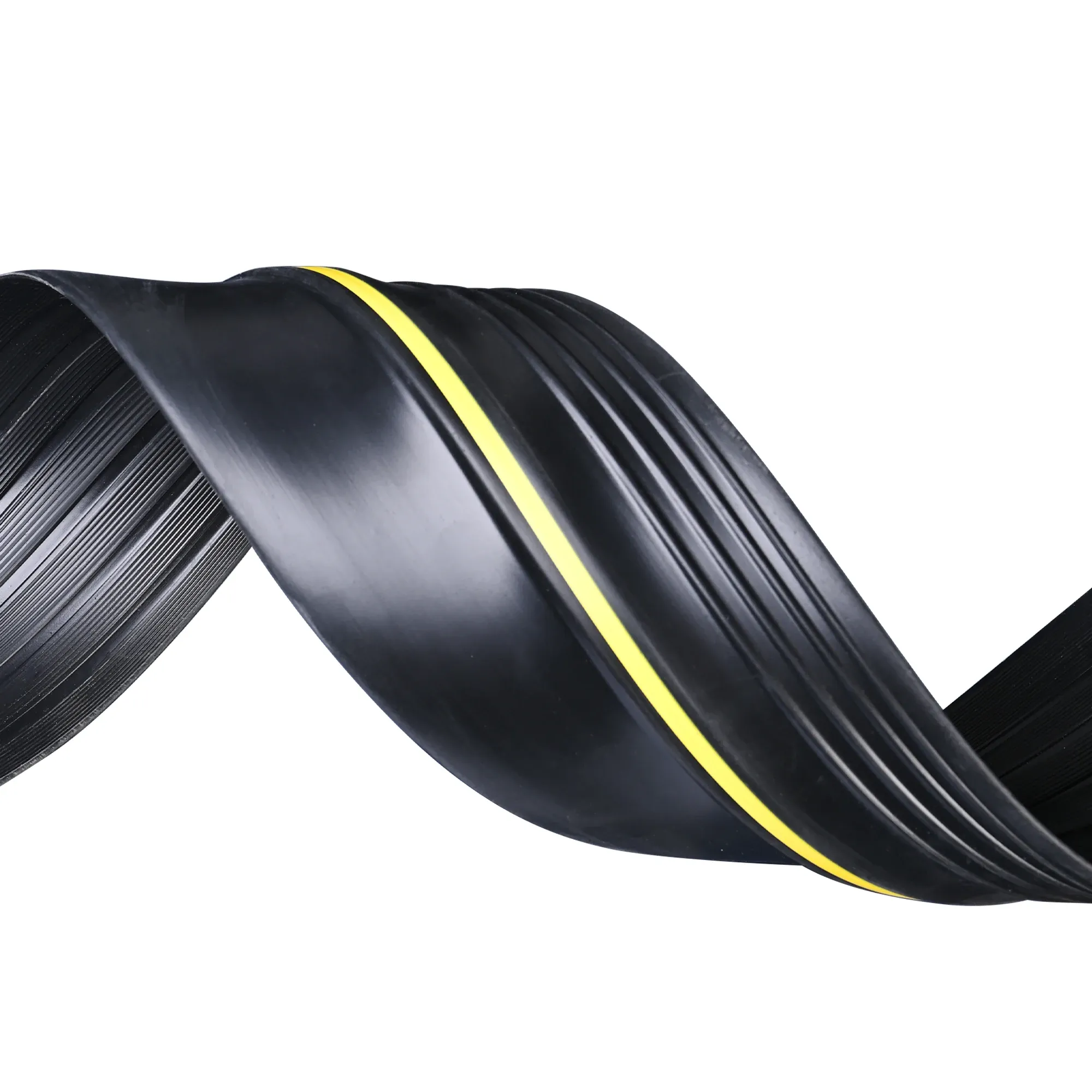

U-shaped plastic profiles, also referred to as C channels, are versatile components used extensively in construction, automotive, and manufacturing sectors. These profiles are characterized by their U shape, which provides significant structural support and stability while allowing for flexibility in design. Made from materials such as PVC, ABS, or polycarbonate, these profiles are light yet strong, combining durability with ease of handling.

Advantages of U-Shaped Profiles

One of the primary advantages of U-shaped plastic profiles is their lightweight nature. Unlike traditional metal channels, plastic profiles reduce the overall weight of structures, making handling and installation more manageable. Furthermore, they are resistant to corrosion, chemicals, and UV exposure, which enhances their longevity in various environments.

The versatility of U-shaped profiles is another key benefit. They can be easily cut, shaped, and assembled according to specific project requirements. This adaptability allows manufacturers to customize profiles for unique applications, whether for roofing systems, decorative edging, or structural reinforcements.

Manufacturing Process C Channel Plastic Extrusion

The process of creating U-shaped plastic profiles typically involves plastic extrusion. This method involves melting raw plastic materials and forcing them through a die that shapes the material into a continuous profile. Once cooled, the extruded plastic can be cut to desired lengths for various applications.

best c channel plastic extrusion u shaped plastic profile

Quality control is crucial in the extrusion process. Manufacturers focus on achieving consistent thickness and dimensions to ensure that the profiles perform as required. Advanced technologies, such as automated measuring systems and calibration tools, are used to monitor parameters during production, guaranteeing high-quality outcomes.

Applications of U-Shaped Profiles

U-shaped plastic profiles find utility across a wide array of sectors. In the construction industry, they serve as components for window frames, cladding, and roofing systems, providing necessary support while enhancing aesthetic appeal. In automotive applications, they can be found in paneling, weather stripping, and decorative trim pieces.

Additionally, manufacturers favor U-shaped profiles for packaging solutions, due to their flexibility and protective capabilities. They can be used to create protective corners for fragile items or serve as structural supports for shipping containers.

Environmental Considerations

With growing concerns over environmental sustainability, many manufacturers are opting for eco-friendly materials in their plastic extrusion processes. Biodegradable plastics and recycled materials offer sustainable alternatives, helping to reduce the carbon footprint associated with production. By focusing on these materials, manufacturers can not only meet evolving consumer preferences but also comply with regulatory standards.

Conclusion

In the realm of plastic extrusions, C channel plastic profiles, particularly in their U-shaped form, stand out due to their versatility, durability, and practical applications across various industries. As the demand for innovative and sustainable solutions continues to rise, manufacturers are likely to invest in advanced technologies and eco-friendly materials, ensuring that U-shaped plastic profiles remain integral to modern design and construction. In summary, understanding the unique qualities and manufacturing processes behind these profiles will aid businesses in making informed decisions that align with both performance and sustainability goals.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025