rubber seal strip for glass supplier

ഡിസം . 11, 2024 12:03 Back to list

rubber seal strip for glass supplier

The Importance of Rubber Seal Strips for Glass Suppliers

In today’s market, the demand for high-quality sealing solutions has witnessed a significant surge, particularly in industries dealing with glass products. Rubber seal strips have emerged as essential components for glass suppliers, ensuring effective sealing, insulation, and protection against various environmental factors. This article explores the importance of rubber seal strips, their applications, and the benefits they bring to glass suppliers.

Understanding Rubber Seal Strips

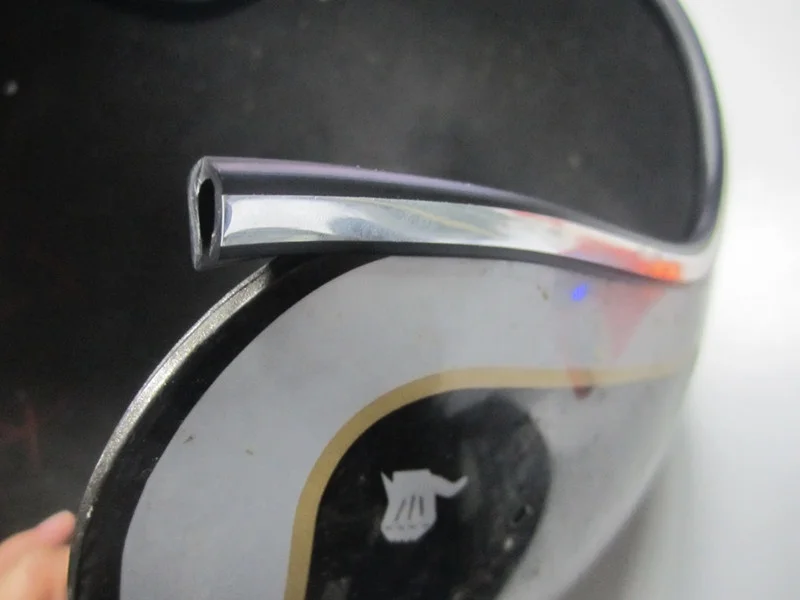

Rubber seal strips are flexible, durable materials designed to create a tight, waterproof, and airtight seal between various surfaces. Made from various rubber compounds, these strips are often used to seal the edges of glass panels in windows, doors, and other applications. Their design allows for easy installation and provides a customizable solution to fit different dimensions and shapes.

Applications in the Glass Industry

For glass suppliers, the integration of rubber seal strips into products is critical. These seal strips can be found in a range of applications, including

1. Windows and Doors Rubber seal strips are commonly used in the glazing of windows and doors. They prevent drafts, moisture, and noise from entering a building, which is essential for energy efficiency and comfort.

2. Automotive Glass In vehicles, rubber seal strips play a crucial role in securing windshields and windows, protecting against water leaks and improving aerodynamics.

4. Display Cases In retail settings, glass display cases use rubber seals to keep dust out and maintain a controlled environment for the items on display.

rubber seal strip for glass supplier

Benefits for Glass Suppliers

The incorporation of rubber seal strips into glass products offers numerous benefits for suppliers, including

1. Enhanced Durability Rubber seal strips improve the longevity of glass installations by buffering against impacts and preventing the glass from moving or shifting. This contributes to overall product durability and reliability.

2. Energy Efficiency With rising energy costs, consumers are increasingly seeking energy-efficient solutions. Rubber seal strips improve insulation, leading to reduced heating and cooling costs and enhancing the building’s energy efficiency.

3. Customization Flexibility Rubber seal strips can be manufactured in various shapes, sizes, and colors, allowing glass suppliers to offer customized solutions that meet the specific needs of their clients.

4. Improved Aesthetic Appeal Beyond functionality, rubber seal strips can enhance the overall appearance of glass installations. They can be designed to blend seamlessly with the glass, creating a clean and modern look.

5. Cost Effectiveness By preventing potential damages associated with water leaks and drafts, rubber seal strips can help suppliers reduce warranty claims and after-sales service costs.

Conclusion

In conclusion, rubber seal strips are an indispensable component for glass suppliers, offering a myriad of benefits that enhance product quality and customer satisfaction. As industries continue to evolve and the demand for efficient sealing solutions grows, the importance of rubber seal strips will only increase. By investing in high-quality rubber seal strips, glass suppliers can not only improve the performance of their products but also solidify their reputation in a competitive market. With advancements in manufacturing techniques and materials, the future of rubber seal strips is promising, paving the way for even more innovative applications in the glass industry.

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025

-

Factory Hot Sale Thin Silicone Sewn Strip Roll Wholesale, Durable & Flexible

NewsJul.30,2025