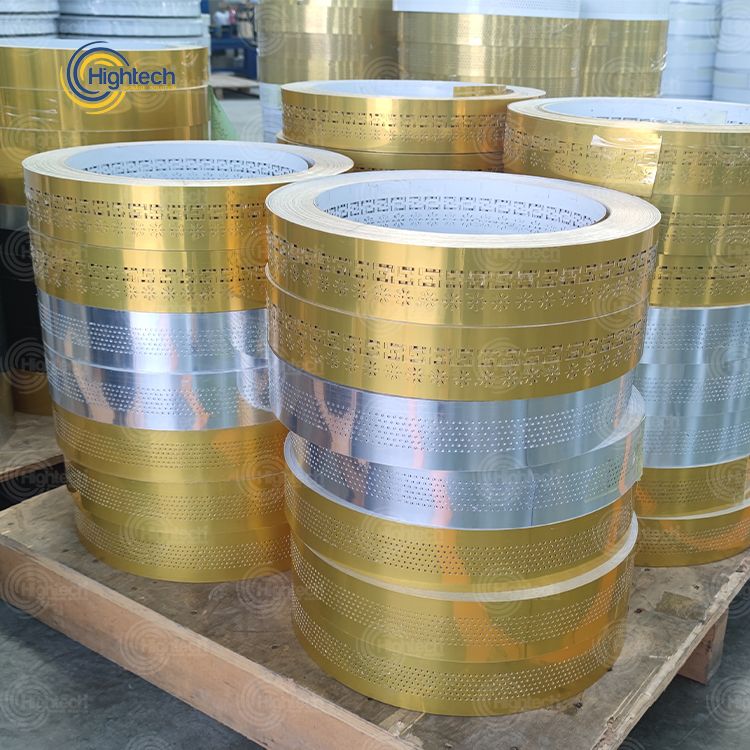

abs strips

Jan . 14, 2025 10:55 Back to list

abs strips

ABS strips are revolutionizing the way industries approach material selection and application. These Acrylonitrile Butadiene Styrene strips, known for their robust physical properties, versatility, and affordability, are weaving their way into countless domains, from construction to automotive, and even in everyday consumer products. Understanding the intricacies of ABS strips' applications, strengths, and industry standards can provide a significant edge in making informed decisions for specific uses.

Moreover, trustworthiness in ABS strips is bolstered by their proven track record. Long-term studies and practical usage cases underscore their consistent performance across different environments and stressors. Whether in consumer product design or large scale infrastructure projects, professionals have commented on the strips’ predictable behavior and lifecycle. By offering an eco-friendly, robust, and economical solution, ABS strips continue to dominate the conversation among product designers and industry engineers striving for sustainability without sacrificing performance. Furthermore, the versatility of ABS strips enhances their appeal to a broad audience. Their ease of molding and thermal adaptability allows for customized applications, permitting intricate designs and variable thicknesses that many competitive materials cannot achieve. The flexibility in design accompanies the inherent traits of the material, offering an expansive canvas for innovation. In conclusion, ABS strips are paving the way for advancements across multiple industries. Their unique combination of durability, environmental compliance, and economic feasibility sets them apart as a material of choice for forward-thinking enterprises. Enhancing production lines with ABS strips may very well serve as the fulcrum for sustainable, quality-conscious growth. As industries continue to evolve, incorporating ABS strips into material strategies could drive new frontiers of engineering and design, ensuring not only compliance and safety but also future-ready innovation.

Moreover, trustworthiness in ABS strips is bolstered by their proven track record. Long-term studies and practical usage cases underscore their consistent performance across different environments and stressors. Whether in consumer product design or large scale infrastructure projects, professionals have commented on the strips’ predictable behavior and lifecycle. By offering an eco-friendly, robust, and economical solution, ABS strips continue to dominate the conversation among product designers and industry engineers striving for sustainability without sacrificing performance. Furthermore, the versatility of ABS strips enhances their appeal to a broad audience. Their ease of molding and thermal adaptability allows for customized applications, permitting intricate designs and variable thicknesses that many competitive materials cannot achieve. The flexibility in design accompanies the inherent traits of the material, offering an expansive canvas for innovation. In conclusion, ABS strips are paving the way for advancements across multiple industries. Their unique combination of durability, environmental compliance, and economic feasibility sets them apart as a material of choice for forward-thinking enterprises. Enhancing production lines with ABS strips may very well serve as the fulcrum for sustainable, quality-conscious growth. As industries continue to evolve, incorporating ABS strips into material strategies could drive new frontiers of engineering and design, ensuring not only compliance and safety but also future-ready innovation.

Next:

Latest news

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025