p seal strip factory

Nov . 22, 2024 05:11 Back to list

p seal strip factory

The Importance of P Seal Strip Factories in Manufacturing

In the world of manufacturing, ensuring products' durability and efficiency is paramount. One often overlooked but crucial component in achieving this is the seal strip, specifically the P seal strip. As manufacturers continuously strive to enhance the performance of their products, P seal strip factories play a significant role in providing the necessary materials to meet industry standards and consumer expectations.

What is a P Seal Strip?

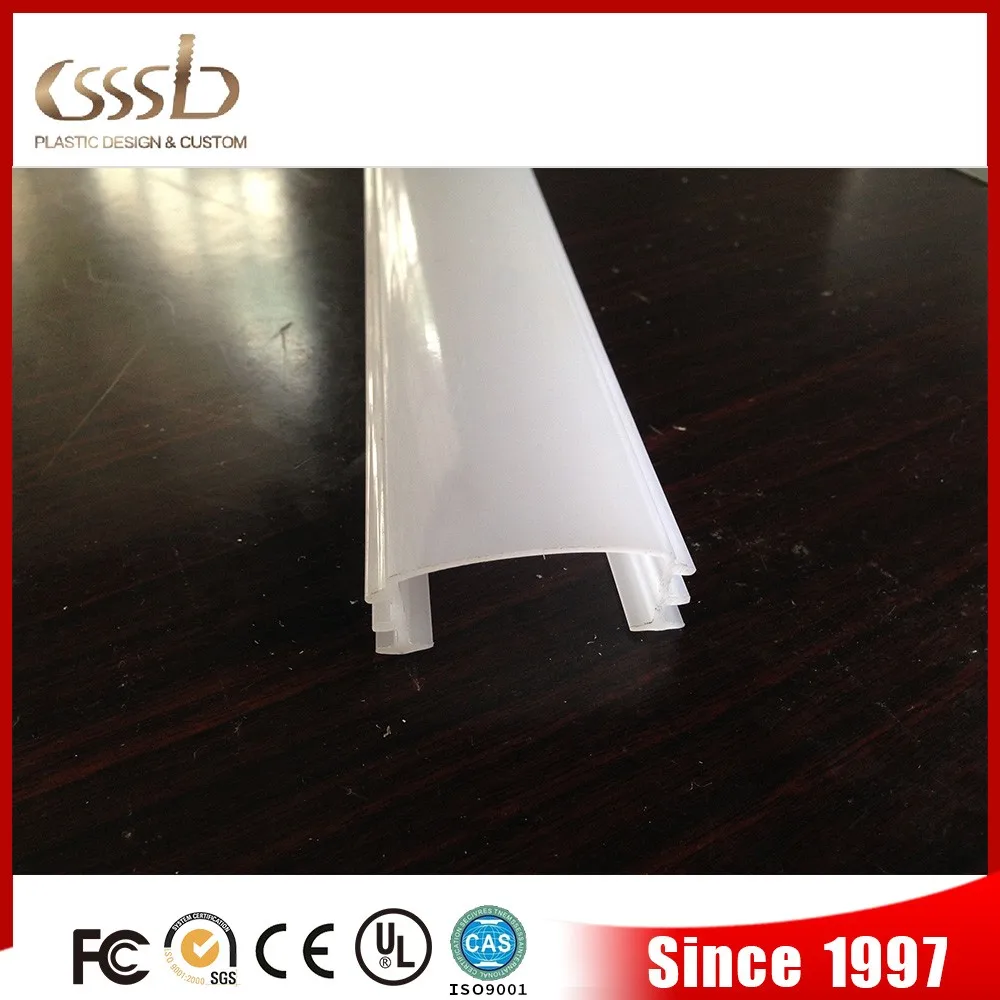

A P seal strip is a type of sealing solution designed to provide an airtight and watertight seal. The P in P seal refers to the shape of the strip, which resembles the letter P. This design creates a flexible and durable barrier against environmental elements such as dust, water, and air leakage. P seal strips are commonly used in various applications, including automotive, construction, and home appliances. Their versatility and effectiveness make them a staple in numerous industries.

The Role of P Seal Strip Factories

P seal strip factories are specialized manufacturing facilities dedicated to the production of these critical sealing components. The process of creating P seal strips involves several steps, including material selection, molding, extrusion, and quality control. The most widely used materials for P seal strips include silicone, rubber, and thermoplastic elastomers (TPE), each offering distinct benefits depending on the application.

1. Material Selection The choice of material is often influenced by the environmental conditions the seal will face. For instance, silicone is preferred for high-temperature applications due to its excellent heat resistance, while rubber may be chosen for its flexibility and durability.

2. Molding and Extrusion Once the material is selected, it undergoes a molding or extrusion process. In molding, the raw material is heated and poured into molds to achieve the desired shape. Extrusion involves forcing the material through a die to create long strips that can be cut to specific lengths. Both methods require precision and expertise to ensure that the final product meets quality standards.

3. Quality Control Before P seal strips are shipped to clients, they undergo rigorous testing to ensure they are free from defects and meet industry specifications. This quality control process is essential for maintaining the integrity of the manufacturing process and ensuring customer satisfaction.

p seal strip factory

Applications of P Seal Strips

P seal strips are used in a wide range of applications, underscoring their importance in the manufacturing sector. In the automotive industry, for example, they are commonly found in door frames and windows to prevent water and noise from entering the vehicle. In construction, P seal strips are essential for windows and doors, providing energy efficiency by preventing air leaks.

Additionally, household appliances like refrigerators and washing machines often utilize P seal strips to maintain temperature and prevent leaks. The effectiveness of these strips contributes to the overall efficiency and longevity of the appliances, highlighting their crucial role in everyday life.

Challenges Faced by P Seal Strip Factories

Despite their importance, P seal strip factories face several challenges. The demand for high-quality seal strips continues to rise, driven by stricter regulations and consumer expectations. As industries evolve, so too must the factories that supply them. Innovations in materials and manufacturing techniques are necessary to stay competitive and meet changing market demands.

Moreover, the increasing emphasis on sustainability presents another challenge. Many manufacturers are seeking eco-friendly materials and processes to reduce their environmental impact. P seal strip factories must adapt by sourcing sustainable materials and implementing green manufacturing practices, which can often involve significant investment and research.

Conclusion

P seal strip factories are a vital part of the manufacturing landscape, producing essential components that contribute to the quality and efficiency of a variety of products. As industries continue to evolve and consumer expectations grow, these factories will need to innovate and adapt to remain competitive. The future of P seal strips lies in their ability to meet these challenges, ensuring that they continue to provide effective sealing solutions in an ever-changing marketplace. Whether in automobiles, construction, or household appliances, the significance of P seal strips cannot be overstated, as they are fundamental to the functionality and reliability of countless products.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025