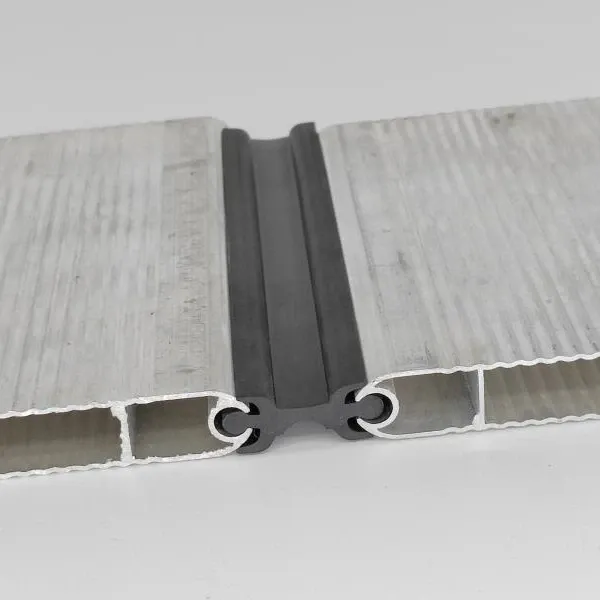

square rubber seal strip

Jan . 28, 2025 04:44 Back to list

square rubber seal strip

When it comes to sealing solutions that ensure durability and performance, square rubber seal strips stand out as a cornerstone in various industries. The importance of these underappreciated components cannot be overstated, as they provide essential sealing and vibration absorption capabilities across a myriad of applications. Harnessing years of industry experience and in-depth knowledge, this piece delves into why square rubber seal strips are indispensable, their manufacturing intricacies, and the optimal ways to employ them for maximum efficiency.

Authoritative knowledge dictates that installation best practices are pivotal for maximizing the efficacy of square rubber seal strips. Always ensure that the surface where the strip will be applied is clean, dry, and free of jagged edges or debris. Proper alignment during installation prevents premature wear and tear. Understanding the specific adhesion requirements or the need for mechanical fastening can greatly enhance sealing performance. Professionals emphasize regular maintenance checks to ensure that the seals remain intact and functional over their lifespan. Trustworthiness in using square rubber seal strips can be gauged by looking at the track record of the suppliers. Leading suppliers in the market often provide certifications that validate not only the quality of the material but also compliance with industry standards such as ISO and ASTM. Their reputation is cemented through consistent delivery of products that stand the test of time, which importantly, minimizes downtime and maintenance costs for enterprises relying on these crucial sealing solutions. In conclusion, square rubber seal strips are more than just components—they are vital to the integrity of systems requiring sealed environments. The combination of expert material selection, cutting-edge manufacturing techniques, authoritative installation guidelines, and the trustworthiness of established suppliers provides a comprehensive approach to utilizing these powerful tools. These strips promise both peace of mind and operational continuity, whether you're sealing the door of an electrical cabinet, lining the edge of a sunroof, or fortifying a weather-exposed junction. By appreciating the nuanced role that square rubber seal strips play, industries can better leverage these components, leading to enhanced performance and extended product lifecycles.

Authoritative knowledge dictates that installation best practices are pivotal for maximizing the efficacy of square rubber seal strips. Always ensure that the surface where the strip will be applied is clean, dry, and free of jagged edges or debris. Proper alignment during installation prevents premature wear and tear. Understanding the specific adhesion requirements or the need for mechanical fastening can greatly enhance sealing performance. Professionals emphasize regular maintenance checks to ensure that the seals remain intact and functional over their lifespan. Trustworthiness in using square rubber seal strips can be gauged by looking at the track record of the suppliers. Leading suppliers in the market often provide certifications that validate not only the quality of the material but also compliance with industry standards such as ISO and ASTM. Their reputation is cemented through consistent delivery of products that stand the test of time, which importantly, minimizes downtime and maintenance costs for enterprises relying on these crucial sealing solutions. In conclusion, square rubber seal strips are more than just components—they are vital to the integrity of systems requiring sealed environments. The combination of expert material selection, cutting-edge manufacturing techniques, authoritative installation guidelines, and the trustworthiness of established suppliers provides a comprehensive approach to utilizing these powerful tools. These strips promise both peace of mind and operational continuity, whether you're sealing the door of an electrical cabinet, lining the edge of a sunroof, or fortifying a weather-exposed junction. By appreciating the nuanced role that square rubber seal strips play, industries can better leverage these components, leading to enhanced performance and extended product lifecycles.

Next:

Latest news

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025