high quality thin silicone beading for aluminum extrusion

Nov . 22, 2024 00:49 Back to list

high quality thin silicone beading for aluminum extrusion

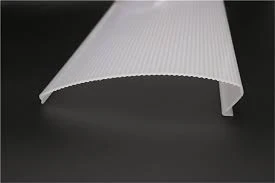

High-Quality Thin Silicone Beading for Aluminum Extrusion An Essential Component for Modern Manufacturing

In contemporary manufacturing and construction, the integration of advanced materials is paramount to achieving durability, efficiency, and functionality. One such material that has gained significant attention is high-quality thin silicone beading, particularly when used in conjunction with aluminum extrusion. This combination not only enhances structural integrity but also offers a myriad of benefits that make it essential for a wide range of applications.

Silicone beading, known for its flexibility and resilience, is an excellent choice for various industries, including automotive, aerospace, electronics, and building construction

. The thin profile of the silicone beading allows for seamless integration into aluminum extrusions, ensuring that it fits snugly without adding excessive bulk. This is particularly important in designs where space is a premium, and weight reduction is a critical factor.One of the primary benefits of using high-quality silicone beading in aluminum extrusion is its superior sealing capabilities. Silicone is inherently resistant to extreme temperatures and environmental conditions, making it an ideal material for creating airtight and watertight seals. This characteristic is especially crucial in applications such as windows, doors, and facades, where exposure to the elements can lead to significant wear and degradation. By incorporating silicone beading, manufacturers can prolong the lifespan of their products, ensuring that they remain functional and aesthetically pleasing over time.

high quality thin silicone beading for aluminum extrusion

Moreover, silicone beading is known for its excellent adhesion properties. When applied correctly, it forms a strong bond with aluminum surfaces, which enhances the overall durability of the assembly. This is vital in applications where structural integrity is paramount, as it minimizes the risk of leaks, drafts, and structural failures. The combination of aluminum's strength with silicone's flexibility creates a robust solution that can withstand the demands of modern usage.

In addition to its functional benefits, silicone beading offers aesthetic advantages as well. Available in various colors and finishes, it can be customized to match any design specification, thereby enhancing the overall appearance of the final product. This adaptability makes it an attractive option for architects and designers who prioritize both form and function in their projects.

Another significant advantage of using thin silicone beading with aluminum extrusion is its resistance to chemicals and UV radiation. Unlike traditional rubber materials, silicone does not degrade or discolor over time when exposed to harsh chemicals or sunlight. This property is essential in applications such as outdoor signage, where longevity and visual appeal are critical. By choosing high-quality silicone beading, manufacturers can ensure that their products maintain their functionality and appearance long after installation.

In conclusion, the use of high-quality thin silicone beading in aluminum extrusion applications represents a significant advancement in manufacturing technology. Its unparalleled sealing capabilities, excellent adhesion, aesthetic versatility, and resistance to environmental factors make it an indispensable component across various industries. As demand for innovative and durable solutions continues to grow, the integration of silicone beading into aluminum extrusions will undoubtedly play a crucial role in the future of manufacturing and construction. Embracing these advanced materials not only leads to enhanced product performance but also promotes sustainability by reducing the need for frequent replacements and repairs. With such compelling advantages, it is clear that high-quality thin silicone beading is the future of reliable and effective engineering solutions.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025