Top Aluminum Coil Options for Easy Hand Use and Handling

डिस . 26, 2024 15:54 Back to list

Top Aluminum Coil Options for Easy Hand Use and Handling

Understanding the Best Aluminum Coil for Hand Use Essential Materials and Practical Applications

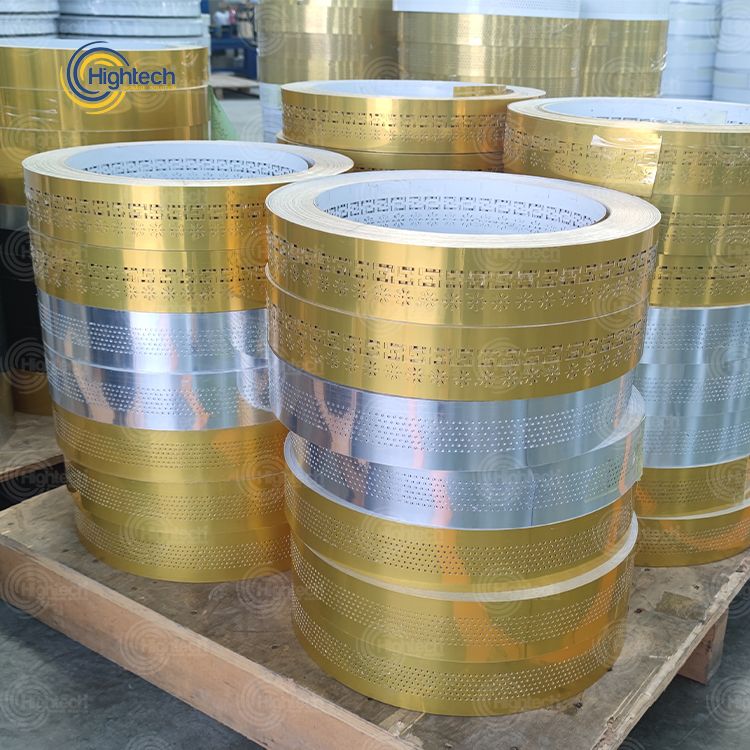

Aluminum coils have become indispensable in various industries due to their lightweight, durability, and versatility. When discussing the best aluminum coil for hand use, it's essential to differentiate between the various alloys, treatments, and specifications that enhance performance for specific applications. In this article, we will explore the best materials for aluminum coils, their properties, and practical uses to aid in selecting the right product for your needs.

The Properties of Aluminum Coils

Aluminum coils offer a unique combination of properties that make them suitable for a wide range of applications. Key attributes include

1. Weight Aluminum is significantly lighter than steel, making it easier to handle, transport, and install. This is particularly beneficial in hand-held applications where weight can affect user fatigue and efficiency.

2. Corrosion Resistance Aluminum naturally forms a protective oxide layer that shields it from corrosion. This quality makes it ideal for outdoor applications and environments where moisture or chemical exposure is a concern.

3. Malleability and Ductility Aluminum can be easily formed and shaped without breaking, which is crucial for applications that require intricate designs or custom fittings. This malleability allows for quick modifications on-site.

4. Thermal Conductivity Aluminum is an excellent conductor of heat, which is useful in applications such as heat exchangers and components in electronic devices.

5. Recyclability Aluminum is 100% recyclable without losing quality, making it an environmentally friendly choice. The sustainability aspect appeals to many businesses and consumers looking to reduce their carbon footprint.

Choosing the Right Aluminum Alloy

When selecting aluminum coils, it is crucial to consider the alloy type. Aluminum alloys are categorized into two main groups wrought and cast. For hand use, wrought alloys are more common. Here are a few popular series

1. 1xxx Series Composed of 99% or higher aluminum, this series is known for its excellent corrosion resistance and thermal conductivity. It is commonly used in electrical applications and food processing due to its non-toxic nature.

best aluminum coil hand use materia

2. 3xxx Series This series includes manganese and offers moderate strength and good workability. It is often used in applications like beverage cans, roofing sheets, and cooking utensils.

3. 5xxx Series Magnesium is the key alloying element in this series, providing good corrosion resistance and good weldability. These alloys are commonly found in marine environments and in the construction of buildings.

4. 6xxx Series This series has magnesium and silicon and is appreciated for its medium strength and good corrosion resistance. It is widely used for structural applications, including scaffolding and frames.

Practical Applications of Aluminum Coils

The versatility of aluminum coils allows for a wide array of practical applications, particularly in sectors that require easy handling and efficiency. Some common uses include

1. Construction Aluminum coils are widely used in roofing, siding, and window frames. Their lightweight nature reduces the overall load on structures while providing durability.

2. Automotive In the automotive industry, aluminum coils are used for body panels, engine components, and in heat exchangers. The reduction in vehicle weight contributes to better fuel efficiency.

3. Electrical Aluminum coils are used in electrical wiring and components due to their excellent conductivity and lightweight properties, making them ideal for overhead power lines and electrical conduits.

4. Packaging Aluminum coils are utilized for packaging materials like aluminum foil and cans, providing airtight seals which are critical for food preservation.

Conclusion

Selecting the best aluminum coil for hand use involves carefully considering the specific application, the required properties, and the desired alloy type. The advantages of aluminum, including its lightweight, strength, and recyclability, make it an ideal choice across various industries. By understanding the different alloys and their properties, users can make informed decisions that enhance their projects and applications, ultimately leading to improved performance and efficiency. Whether you're in construction, automotive, electrical, or another sector, embracing the versatility of aluminum coils is a step towards achieving your objectives effectively.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025