oem aluminum coils

नोभ . 04, 2024 12:39 Back to list

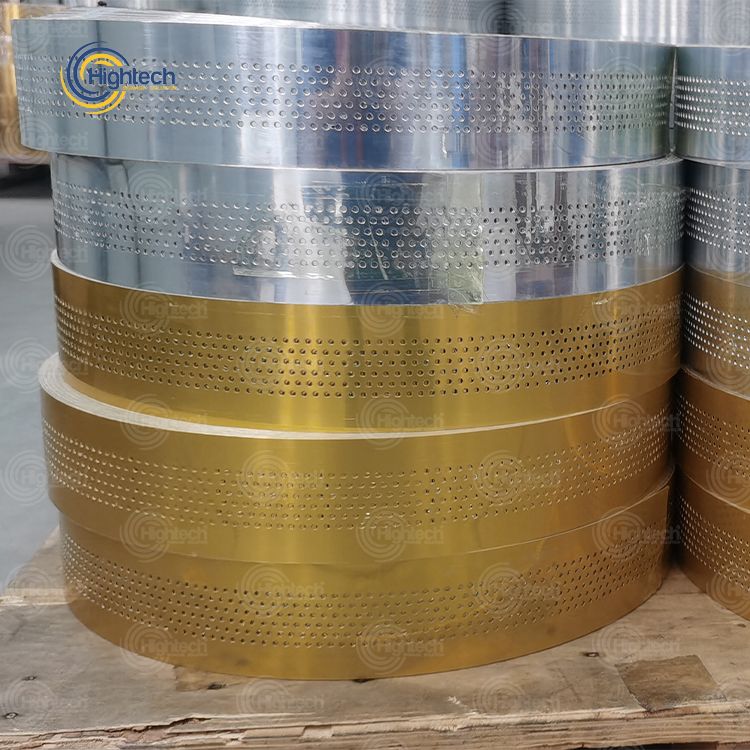

oem aluminum coils

Understanding OEM Aluminum Coils Applications and Benefits

Aluminum coils are versatile materials that play a significant role in various industries. Among the various forms of aluminum products, OEM (Original Equipment Manufacturer) aluminum coils stand out due to their tailored specifications to meet particular requirements of customers. This article explores the characteristics, applications, and advantages of OEM aluminum coils.

What Are OEM Aluminum Coils?

OEM aluminum coils are manufactured according to specific designs and standards requested by clients. These coils are produced in bulk and can be customized in terms of thickness, width, alloy composition, and surface treatment. This flexibility allows manufacturers to cater to the unique needs of different industries, ensuring that the materials used fit perfectly into their production processes.

Applications of OEM Aluminum Coils

The applications of OEM aluminum coils are vast and diverse. They are commonly used in industries such as automotive, aerospace, construction, packaging, and electrical engineering.

1. Automotive Industry In the automotive sector, OEM aluminum coils are used for components such as body panels, heat exchangers, and structural parts. Their lightweight nature contributes to fuel efficiency while offering superior strength and durability.

2. Aerospace Sector The aerospace industry relies on OEM aluminum coils for aircraft components because of their excellent strength-to-weight ratio and corrosion resistance. These properties enhance aircraft performance and longevity.

oem aluminum coils

3. Construction and Architecture In construction, OEM aluminum coils are utilized for roofing, siding, and decorative applications. The material's resistance to weathering and low maintenance requirements make it an ideal choice for facades and structures exposed to the elements.

4. Packaging Industry Aluminum coils are crucial in packaging applications, particularly in food and beverage packaging. Their lightweight and recyclable nature makes them environmentally friendly and cost-effective, aligning with current sustainability goals.

5. Electrical Engineering In electrical applications, OEM aluminum coils are employed for wire, cables, and other conductive components. Aluminum’s conductivity combined with its lightweight properties makes it a suitable choice for reducing energy costs in power transmission.

Advantages of Using OEM Aluminum Coils

There are several advantages associated with using OEM aluminum coils. Firstly, customization allows manufacturers to optimize their production lines, resulting in higher efficiency and reduced waste. Secondly, aluminum's inherent properties, such as resistance to corrosion, lightweight structure, and high strength, offer significant savings in transportation and maintenance costs.

Moreover, aluminum is highly recyclable, making it an environmentally sustainable choice. By using OEM aluminum coils, manufacturers can not only meet their specific requirements but also contribute positively to sustainability efforts.

Conclusion

In conclusion, OEM aluminum coils are essential components across a myriad of industries, providing tailored solutions to meet specific needs. Their lightweight, durable, and corrosion-resistant nature offers multiple advantages, making them a preferred choice in modern manufacturing processes. As industries continue to evolve, the relevance and demand for customized aluminum solutions are set to grow, driving innovation and efficiency in the marketplace.

-

Top Window Seal Strip Adhesive Companies for Quality Export Solutions

NewsJul.29,2025

-

Top Window Seal Strip Adhesive Companies & Suppliers for Quality Products

NewsJul.29,2025

-

Air Filter Replacement Core for K-archer WD4.200 WD5.200 WD4 WD5

NewsJul.28,2025

-

Top Window Seal Strip Adhesive Companies for Durable Solutions

NewsJul.27,2025

-

Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter

NewsJul.26,2025

-

Factory Hot Sale Recycled Green Elastic Profiles Wholesale Supplier

NewsJul.25,2025