Flexible Flat PVC Silicone Strips 10x3mm for Versatile Applications and Custom Solutions

Dec . 11, 2024 09:34 Back to list

Flexible Flat PVC Silicone Strips 10x3mm for Versatile Applications and Custom Solutions

The Rise of Flexible Flat PVC and Silicone Solutions A Focus on 10x3mm Applications

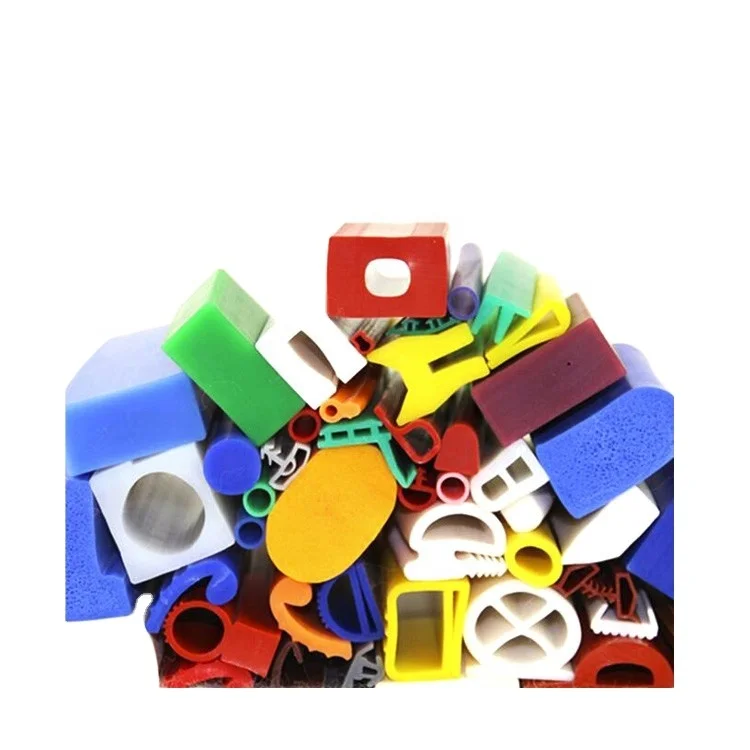

In the ever-evolving landscape of materials science and manufacturing, flexible flat PVC and silicone have emerged as critical components in numerous industries due to their versatility and durability. With dimensions like 10x3mm, these materials find diverse applications, serving various industrial needs—from automotive components to consumer electronics.

Understanding Flexible Flat PVC and Silicone

Flexible PVC (Polyvinyl Chloride) is a widely used plastic known for its resilience, flexibility, and cost-effectiveness. It can be easily molded into different shapes, making it ideal for applications where versatility is crucial. On the other hand, silicone is renowned for its heat resistance, chemical stability, and non-toxicity. This makes it especially valuable in environments that require high-performance materials, such as medical devices and food industry applications.

The 10x3mm dimension is particularly significant as it reflects a common size suitable for a range of uses, including electrical insulation, seals, gaskets, and protective coverings. Companies specializing in the production of these materials have recognized the growing demand for such specifications, tailoring their offerings to meet industry standards.

Applications Across Industries

1. Automotive Industry In the automotive sector, flexible flat PVC and silicone are utilized for creating interior components such as door seals, insulation panels, and dashboard coverings. The 10x3mm size is ideal for gasket applications, ensuring a snug fit that prevents water and air leaks, which is critical for vehicle performance and passenger comfort.

2. Electronics The flexible nature of PVC and silicone makes them imperative in the electronics field. They are often employed as cable insulators and protective sheathing, safeguarding electrical components from damage caused by abrasion or extreme temperatures. The specific dimension of 10x3mm allows for effective bending and routing in tight spaces, making it suitable for modern electronic devices.

10x3mm flexible flat pvc silicone company

3. Medical Devices In the healthcare industry, silicone is especially favored for its biocompatibility and resistance to microbial growth. Applications include surgical instruments, tubing, and patient monitoring equipment. The flat and flexible design can be essential for devices that require secure yet adaptable materials that can conform to various shapes and surfaces.

4. Construction and Infrastructure Flexible flat PVC is also a key player in construction and infrastructure projects. Its waterproof and UV-resistant properties make it ideal for outdoor applications, such as roofing membranes and window seals. Gaskets and seals produced in the 10x3mm dimension provide essential barriers against moisture and air, enhancing the energy efficiency of buildings.

5. Consumer Products From household appliances to personal care items, flexible flat PVC and silicone are integrated into many consumer products. Their moldable nature allows for innovative designs, making them appealing to manufacturers striving for both functionality and aesthetics. The precise 10x3mm size can be crucial in products where space is a premium, ensuring that the materials used have the desired appearance and performance.

Environmental Considerations

With the growing emphasis on sustainability, manufacturers of flexible flat PVC and silicone are also exploring eco-friendly alternatives. Innovations such as bio-based PVC and silicone materials reduce environmental impact, aligning with the global push toward sustainable practices. Companies are investing in research and development to explore these alternatives without compromising on quality and performance.

Conclusion

The flexibility, durability, and adaptability of flat PVC and silicone materials, particularly in sizes like 10x3mm, have positioned them as invaluable assets across various industries. Their capacity to meet specific design criteria while conforming to regulatory standards ensures their continued relevance in a competitive market. As technology advances and industries evolve, companies specializing in these materials will play a pivotal role in shaping the future, driven by innovation and a commitment to sustainability.

In summary, flexible flat PVC and silicone manufacturers are not just providers of materials; they are partners in progress, helping industries create products that are not only functional but also responsible and forward-thinking.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025