3D High-Quality Polymer ABS Strips Manufacturing Facilities and Production Techniques

Nov . 09, 2024 15:12 Back to list

3D High-Quality Polymer ABS Strips Manufacturing Facilities and Production Techniques

The Rise of 3D High Polymer ABS Strips A Revolution in Manufacturing

In recent years, the manufacturing industry has witnessed a paradigm shift, driven by advancements in 3D printing technology. Among the various materials that have gained popularity in this space, ABS (Acrylonitrile Butadiene Styrene) stands out for its superior qualities and versatility. As factories specializing in 3D high polymer ABS strips emerge, they are revolutionizing how products are designed, produced, and brought to market.

What is ABS?

ABS is a thermoplastic polymer known for its strength, toughness, and ability to resist impact. It is a popular choice in various applications, from consumer goods and automotive components to electronics and medical devices. The rise of 3D printing has opened new avenues for ABS, allowing for more intricate designs and shorter production times. With the ability to create high-quality ABS strips in various sizes and configurations, manufacturers can meet specialized demands more effectively than ever before.

The Importance of 3D Printing in Manufacturing

One of the most significant advantages of using 3D printing technology in the production of ABS strips is the ability to create complex geometries that are often impossible to achieve through traditional manufacturing methods. This capability not only enhances the design possibilities but also reduces material waste, thereby improving sustainability. Additionally, 3D printing allows for rapid prototyping, enabling companies to test and iterate on designs much faster than before. This accelerated development cycle is critical in today’s fast-paced market, where consumer preferences can shift rapidly.

Factories Specializing in 3D High Polymer ABS Strips

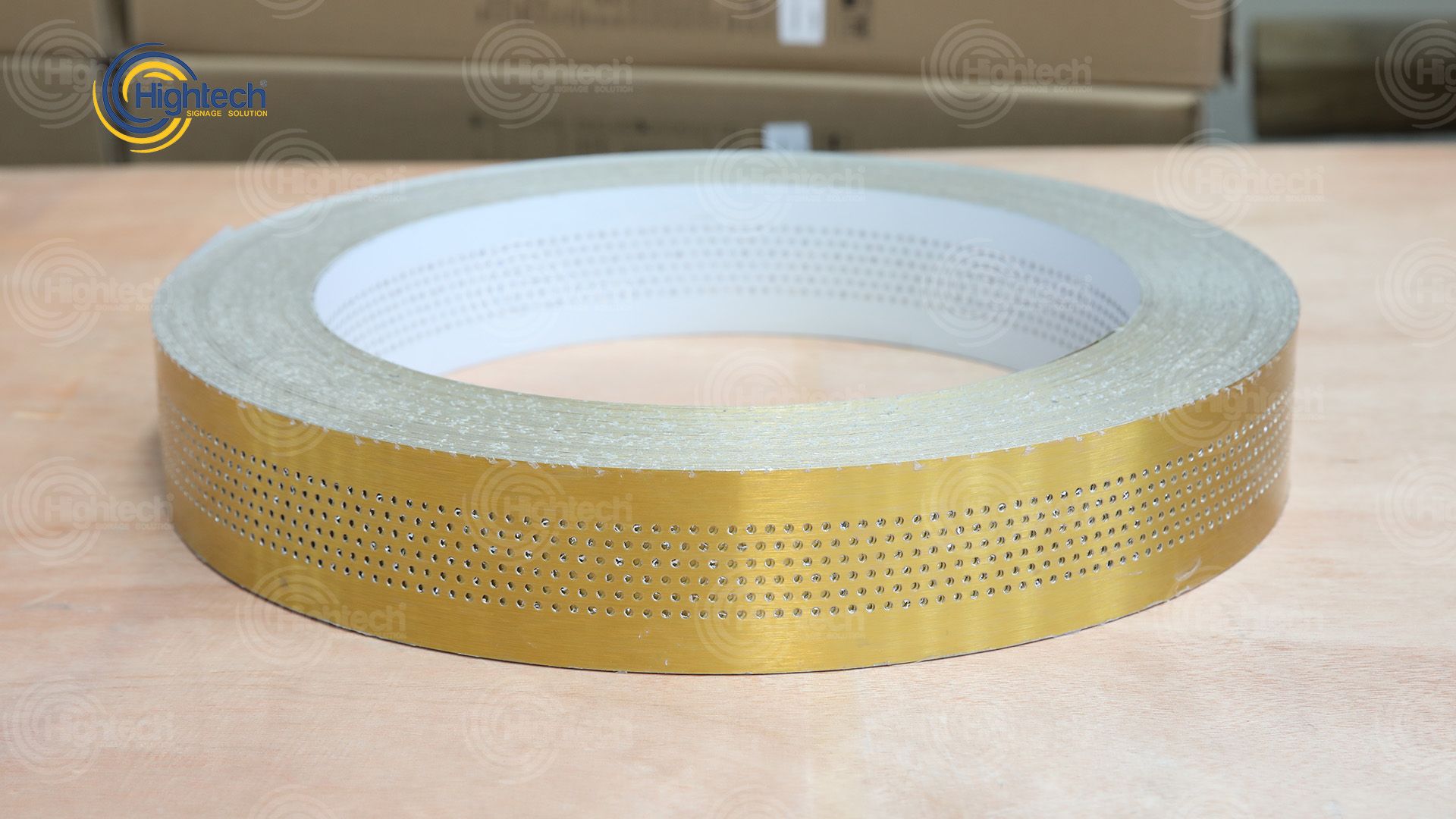

As the demand for customized and efficient manufacturing grows, factories focusing on 3D high polymer ABS strip production are becoming increasingly prevalent. These specialized facilities harness advanced 3D printing technologies and high-quality raw materials to produce ABS strips that cater to a range of applications.

Equipped with state-of-the-art machinery and skilled personnel, these factories can produce ABS strips in various lengths, thicknesses, and colors, offering clients the flexibility they need for their projects. The use of high polymer ABS ensures that the resulting products boast excellent durability and aesthetic appeal, making them suitable for various industries.

3d high polymer abs strips factories

Benefits for Industries

Industries across the board are reaping the benefits of using 3D high polymer ABS strips. In the automotive sector, for example, manufacturers are utilizing these strips for everything from prototypes to final components, leveraging the material’s strength and weight advantages. In consumer electronics, innovative designs are emerging thanks to the versatility of ABS strips, which can be precisely tailored to fit unique product specifications.

Furthermore, the medical field has also begun to explore the potential of 3D printed ABS strips. Customizable and biocompatible solutions mean that medical devices can be tailored to individual patient needs, enhancing healthcare outcomes.

Future Trends

Looking ahead, the future of 3D high polymer ABS strip manufacturing appears bright. As technology continues to evolve, we can expect to see even greater efficiency, precision, and cost-effectiveness in the production process. Innovations like automation and artificial intelligence could streamline operations, while advancements in material science may lead to the development of even more specialized ABS formulations.

Additionally, the growing focus on sustainability will likely push factories to adopt eco-friendly practices, such as recycling waste materials and reducing energy consumption during production. Consumers are increasingly looking for products that are not only high-quality but also environmentally responsible, making sustainability a crucial factor in the manufacturing landscape.

Conclusion

The emergence of 3D high polymer ABS strip factories marks a significant evolution in manufacturing capabilities. With their ability to produce durable, customizable, and intricately designed products, these factories are meeting the diverse needs of various industries. As technology continues to advance, we can anticipate even more innovative applications and benefits, solidifying the role of 3D printing as a cornerstone of modern manufacturing.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025