5cm 3d high polymer manufacturer

Dec . 06, 2024 17:14 Back to list

5cm 3d high polymer manufacturer

The Rise of 5cm 3D High Polymer Manufacturing

In recent years, the field of 3D printing has experienced rapid advancement, with various materials and techniques emerging to enhance the capabilities of this innovative technology. One notable development is the rise of high polymer manufacturing, particularly within compact dimensions like 5cm. This article explores the significance of 5cm 3D high polymer manufacturing, its applications, benefits, and future prospects.

Understanding High Polymer Materials

High polymers are large molecules composed of repeated subunits, known for their versatile properties such as flexibility, durability, and resistance to chemicals. Unlike other materials like metals or ceramics, high polymers can be easily manipulated and molded, making them suitable for 3D printing applications. The ability to create intricate designs at a 5cm scale offers unique opportunities in various sectors, including medical, automotive, and consumer goods.

Applications of 5cm 3D High Polymer Manufacturing

1. Medical Devices One of the most impactful areas of high polymer manufacturing is in the medical field. With precision 3D printing, medical professionals can produce customized implants, prosthetics, and surgical tools tailored to individual patients' needs. For example, a 5cm prosthetic finger can be designed to fit perfectly and comfortably for users, enhancing overall functionality and acceptance.

2. Automotive Components The automotive industry has also begun to adopt high polymer components produced through 3D printing. Businesses can create lightweight, durable parts that enhance fuel efficiency while maintaining performance. Small, intricate components such as brackets or dashboard elements can be optimally designed at a 5cm scale, allowing for efficient use of space and weight reduction.

3. Consumer Products The demand for personalized products continues to rise in the consumer goods market. With 5cm high polymer 3D printing, manufacturers are able to produce custom phone cases, accessories, and even unique furniture designs. This level of customization not only meets individual tastes but can also streamline production processes and reduce waste.

5cm 3d high polymer manufacturer

Benefits of 5cm High Polymer Manufacturing

The advantages of using 5cm high polymer manufacturing in various industries are numerous

- Cost Efficiency Smaller-scale production reduces material waste and allows for lower raw material costs. Additionally, the ability to produce components on-demand minimizes inventory costs, leading to increased overall efficiency.

- Speed of Production 3D printing technology significantly accelerates the manufacturing process. High polymer materials can be printed quickly, enabling rapid prototyping and timely product development, beneficial for businesses under tight deadlines.

- Design Flexibility The nature of 3D printing allows for complex geometries and innovative designs that would be difficult or impossible to achieve with traditional manufacturing methods. This flexibility facilitates creativity and innovation in product design.

Future Prospects

As technology continues to evolve, the future of 5cm high polymer manufacturing looks promising. Research is underway to enhance the mechanical properties of high polymers, making them even more suitable for demanding applications. Furthermore, advancements in printing techniques, such as multi-material printing, will allow for the combination of properties from different polymers, opening up new possibilities for innovation.

In conclusion, 5cm 3D high polymer manufacturing is transforming how industries approach design and production. From customized medical devices to unique consumer products, the versatility and advantages of high polymers make them a valuable resource in the world of manufacturing. As we continue to embrace these technologies, the potential for even greater innovations lies ahead, paving the way for a future where customized, efficient, and sustainable production becomes the norm.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

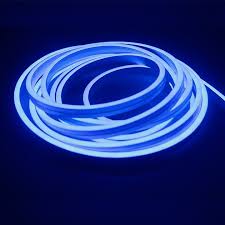

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025