Aluminum Coil Manual Use Material Manufacturers and Suppliers Guide

Nov . 25, 2024 08:53 Back to list

Aluminum Coil Manual Use Material Manufacturers and Suppliers Guide

The Utilization of Aluminum Coil in Hand Use Applications A Focus on Factories

Aluminum coils have become a staple in various industries, owing to their versatility, lightweight, and corrosion resistance

. This article explores the significance of aluminum coils in hand use applications and their production within factories.Aluminum is a remarkable metal; it is known for its excellent strength-to-weight ratio and resistance to oxidation. These properties make it an ideal choice for manufacturing products that require durability and efficiency. The production of aluminum coils involves a complex process that begins with the extraction of bauxite ore, which is then refined into aluminum oxide. This is subsequently smelted to produce aluminum, which can be rolled into coils of varying thicknesses and widths.

The manufacturing of aluminum coils suitable for hand use focuses on ensuring that the material meets specific quality standards. Factories producing these coils employ advanced techniques and machinery to achieve the desired specifications. Modern rolling mills can reduce aluminum sheets to very thin gauges, allowing for lightweight applications without compromising strength. These thin aluminum coils can then be used in numerous everyday products, from kitchenware to automotive parts.

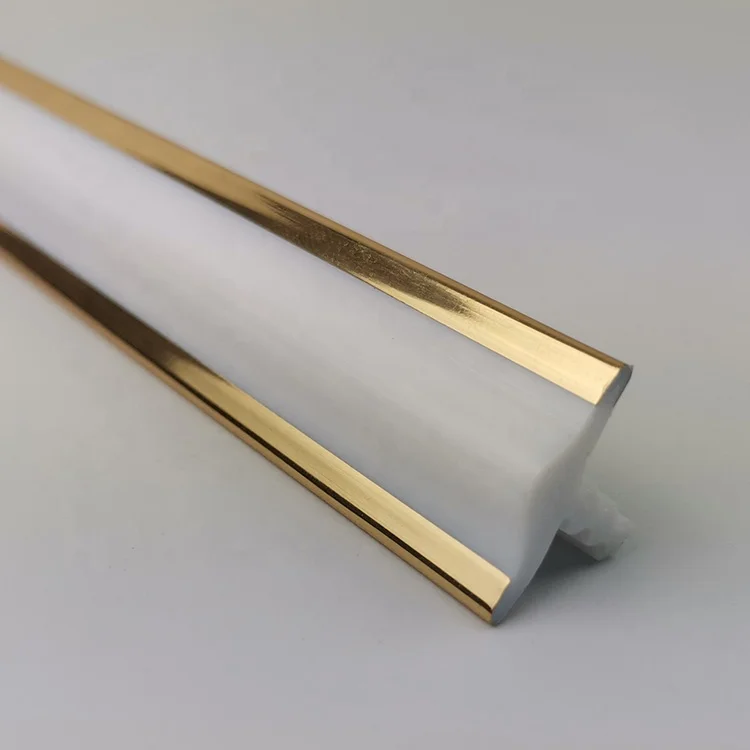

aluminum coil hand use materia factories

One of the primary advantages of aluminum coils is their ability to be easily formed into different shapes, making them particularly useful for hand-crafted items. Artisans and manufacturers utilize aluminum coils to create everything from decorative elements and home furnishings to functional tools. The malleability of aluminum allows for intricate designs and custom applications, broadening the scope for creative and practical uses.

Moreover, the aluminum coil is also favored in the manufacturing of products that require good thermal and electrical conductivity. This makes aluminum coils essential in industries such as HVAC, electronics, and renewable energy. Factories focus on producing coils that comply with industry standards to ensure safety and efficiency in various applications.

Sustainability is another crucial factor driving the demand for aluminum coils. Aluminum is 100% recyclable without loss of quality. Many factories have instituted recycling programs to make use of scrap aluminum generated during production, minimizing waste and reducing environmental impact. This eco-friendly approach not only benefits the planet but also enhances the overall brand image of manufacturers committed to sustainable practices.

In conclusion, the production of aluminum coils suitable for hand use applications has several implications for both artisans and industries. Factories play a crucial role in ensuring that these materials are produced to meet specific requirements, promoting their use across various sectors. As sustainability continues to be a significant focus, the future of aluminum coils in hand use applications looks promising, with increasing innovations and efficient manufacturing processes paving the way for new possibilities. Whether for artistic creations or practical tools, aluminum coils stand as a testament to the metal's adaptability and enduring relevance in modern manufacturing.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025