best strip seal joints

Dec . 07, 2024 16:35 Back to list

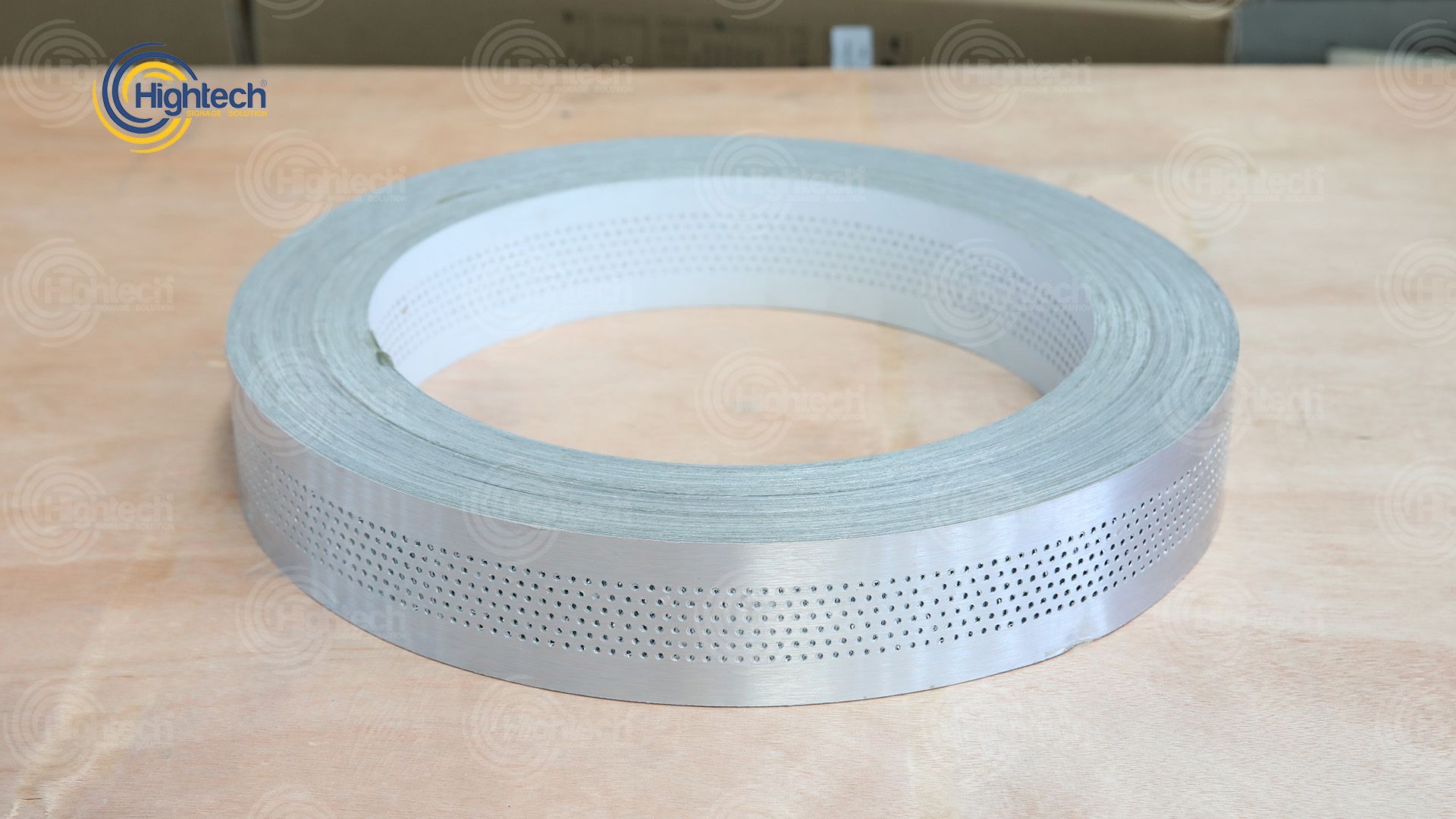

best strip seal joints

Best Strip Seal Joints A Comprehensive Overview

In the construction and civil engineering sectors, the integrity and longevity of structures are of paramount importance. One critical component that plays a significant role in ensuring durability and reliability is the strip seal joint. This article will delve into the best practices, features, applications, and advantages of strip seal joints, helping you understand why they are a preferred solution for many engineers and contractors.

What are Strip Seal Joints?

Strip seal joints are specialized joints used primarily in bridges and pavement structures, designed to accommodate movements while preventing the ingress of water and debris. These joints consist of a flexible, elastomeric material (often rubber) that is contained within a structural frame, ensuring that they can absorb dynamic loads and movements resulting from thermal expansion, traffic, and settlement.

Key Features

1. Durability Strip seal joints are engineered to withstand extreme weather conditions, high traffic loads, and constant movement, ensuring a longer lifespan compared to other types of joints.

2. Waterproofing One of the standout features of strip seal joints is their ability to prevent water leakage. This characteristic is crucial for protecting the underlying structures from corrosion and deterioration.

3. Flexibility The elastomeric materials used in strip seal joints allow for flexibility, which is essential in accommodating various types of movement, whether from thermal expansion, contraction, or the dynamic forces exerted by vehicles.

5. Versatility These joints can be used in various applications, including highway and railway bridges, parking garages, and even in airport runways, making them a versatile solution in structural engineering.

Applications

best strip seal joints

Strip seal joints find their primary application in bridge structures, where accommodating movement is essential for structural integrity. They are ideal for

- Bridges Allowing for horizontal and vertical movements caused by temperature changes and structural settling. - Highways and Roads Ensuring smooth transitions and durability in areas subjected to constant vehicular stress. - Airport Runways Providing stability and safety in areas where aircraft movement is frequent and intense.

Advantages

The advantages of choosing strip seal joints over other types include

1. Cost-Effectiveness While initial investment costs may be higher than simpler solutions, their durability and low maintenance requirements lead to cost savings in the long run.

2. Reduced Maintenance Once installed, strip seal joints typically require less maintenance compared to traditional joints, which can suffer from wear and tear more quickly.

3. Aesthetic Appeal With their sleek design, strip seal joints offer a more visually appealing solution, contributing to the overall aesthetic of the structure.

4. Safety By preventing water ingress and minimizing structural movement, strip seal joints enhance the safety of users by reducing the risks of surface cracks and failures.

Conclusion

In summary, strip seal joints are an advanced joint solution that offers numerous benefits, making them an essential component in modern civil engineering projects. With features such as durability, waterproofing, and flexibility, strip seal joints are designed to mitigate the challenges posed by environmental factors and structural demands. As infrastructure continues to be a focus in urban development, the adoption of such innovative solutions will ensure that structures are not only functional but also resilient over time. Whether you are an engineer, contractor, or project manager, understanding the importance and advantages of strip seal joints will enable you to make informed decisions for your projects, ensuring safety, longevity, and cost-effectiveness.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025