Manufacturer of High-Quality Black Rubber Seal Strip for Various Applications

Dec . 09, 2024 17:46 Back to list

Manufacturer of High-Quality Black Rubber Seal Strip for Various Applications

The Significance and Manufacturing Process of Black Rubber Seal Strips

In various industries, the importance of effective sealing solutions cannot be overstated. Among these solutions, black rubber seal strips are widely recognized for their versatility and reliability. Found in countless applications—from automotive and construction to electronics and appliances—these seals serve a critical role in ensuring durability and performance. This article delves into the significance of black rubber seal strips, their manufacturing process, and the factors to consider when sourcing them from a factory.

Importance of Black Rubber Seal Strips

Black rubber seal strips are essential components designed to prevent the ingress of dust, moisture, air, and other contaminants. Their primary function is to create a barrier between different environments, thus enhancing the longevity and efficiency of products. For instance, in vehicles, seal strips are utilized in doors and windows to mitigate wind noise and water leakage. In appliances, they ensure that energy is conserved by preventing cold air from escaping refrigerators and freezers.

Furthermore, the rubber material provides elasticity, which allows for easy installation and a snug fit. This adaptability makes black rubber seals an ideal choice for irregular surfaces or challenging configurations. In addition to their functional benefits, these seals are often favored for their aesthetic appeal, as the dark color offers a sleek, unobtrusive look.

Manufacturing Process of Black Rubber Seal Strips

The production of black rubber seal strips typically involves several key stages

1. Material Selection The most commonly used materials for these seals include EPDM (Ethylene Propylene Diene Monomer), neoprene, and silicone rubber. Each material possesses unique properties, influencing factors such as durability, flexibility, and resistance to environmental elements.

2. Compounding The chosen rubber material is processed through compounding, where various additives are incorporated. These additives improve specific characteristics such as UV resistance, flame retardancy, and tensile strength. The formulation is crucial, as it defines the seal's performance in various conditions.

3. Molding Once the compound is ready, it is subjected to molding, a pivotal step in the manufacturing process. The compound is heated and placed in molds that shape the seal strips according to specific designs. Various molding techniques, including extrusion and compression molding, are utilized based on the required dimensions and profiles.

black rubber seal strip factory

4. Curing Following molding, the rubber undergoes a curing process, often referred to as vulcanization. This process involves heating the rubber in the presence of sulfur, which creates cross-links between the polymer chains. Curing enhances the rubber's elasticity and durability, resulting in a final product that can withstand stress and environmental variables.

5. Quality Control Before the black rubber seal strips are packaged and shipped, they undergo rigorous quality checks. Manufacturers utilize various testing methods to measure physical properties, including hardness, tensile strength, and elongation. Ensuring that the products meet industry standards is critical for maintaining safety and performance.

Factors to Consider When Sourcing from a Factory

When looking to source black rubber seal strips from a factory, several factors should be taken into account

- Experience and Reputation It is vital to partner with a manufacturer that has a proven track record in producing high-quality rubber products. Researching customer testimonials and industry ratings can provide insights into a factory’s reliability.

- Customization Capabilities Different applications may require bespoke solutions. Therefore, finding a factory that offers customization options ensures that you receive seal strips tailored to your specific needs.

- Compliance and Certifications Ensure that the manufacturer adheres to industry standards and holds relevant certifications. This compliance guarantees product safety and performance, which is especially important in sensitive applications such as food processing and pharmaceuticals.

- Cost and Lead Times While pricing is a critical factor, the cheapest option is not always the best. Consider the balance between cost, quality, and delivery timelines to ensure that your operational needs are met without compromising quality.

In conclusion, black rubber seal strips are vital components across myriad industries, providing effective sealing solutions that enhance product performance. Understanding their significance, manufacturing processes, and factors to consider when sourcing them can help businesses make informed decisions to acquire the best sealing solutions for their needs.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

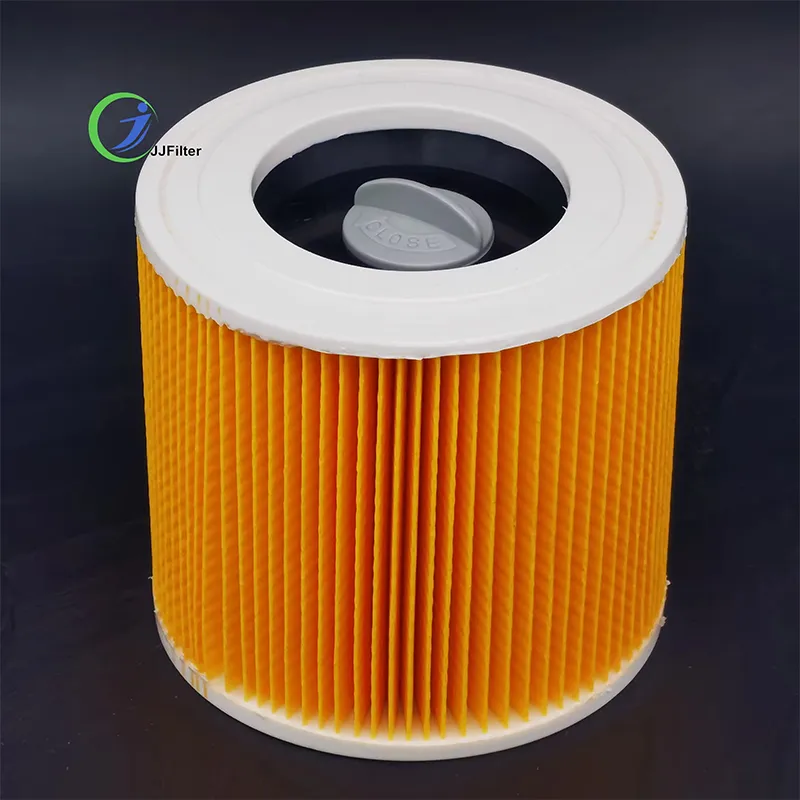

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025