EPDM Sponge Seal Certification for Enhanced Performance and Reliability in Sealing Applications

Dec . 14, 2024 23:27 Back to list

EPDM Sponge Seal Certification for Enhanced Performance and Reliability in Sealing Applications

EPDM Sponge Seal Certification What You Need to Know

In the realm of industrial applications and consumer products, sealing materials play a pivotal role in ensuring efficiency, durability, and safety. One of the standout materials in this category is Ethylene Propylene Diene Monomer (EPDM) rubber, especially when formed into sponge seals. This article explores the importance of EPDM sponge seal certification, its benefits, and its applications.

Understanding EPDM Sponge Seals

EPDM is a type of synthetic rubber that is particularly esteemed for its durability and resistance to environmental factors such as heat, ozone, and weathering. When produced in sponge form, it incorporates a cellular structure that enhances its flexibility and compression set. This unique combination makes EPDM sponge seals ideal for various industries, including automotive, construction, and HVAC systems.

The Importance of Certification

Certifying EPDM sponge seals ensures that they meet specific industry standards and regulatory requirements. Certifications can affirm the material's performance capabilities, safety measures, and compliance with environmental regulations.

1. Quality Assurance Certification processes typically involve rigorous testing to evaluate the material’s physical properties, thermal stability, and resistance to chemicals. Manufacturers who have their products certified can assure customers of their quality and reliability.

2. Health and Safety Compliance Many industries today prioritize health and safety standards. Certification demonstrates that EPDM sponge seals do not contain harmful substances and comply with regulations such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances). This compliance is critical, particularly in the automotive and healthcare sectors.

3. Environmental Impact As businesses and consumers become increasingly focused on sustainability, certified products often give a competitive advantage. Certified EPDM sponge seals can be marketed as environmentally friendly, particularly if they are produced using eco-efficient methods or recycled materials.

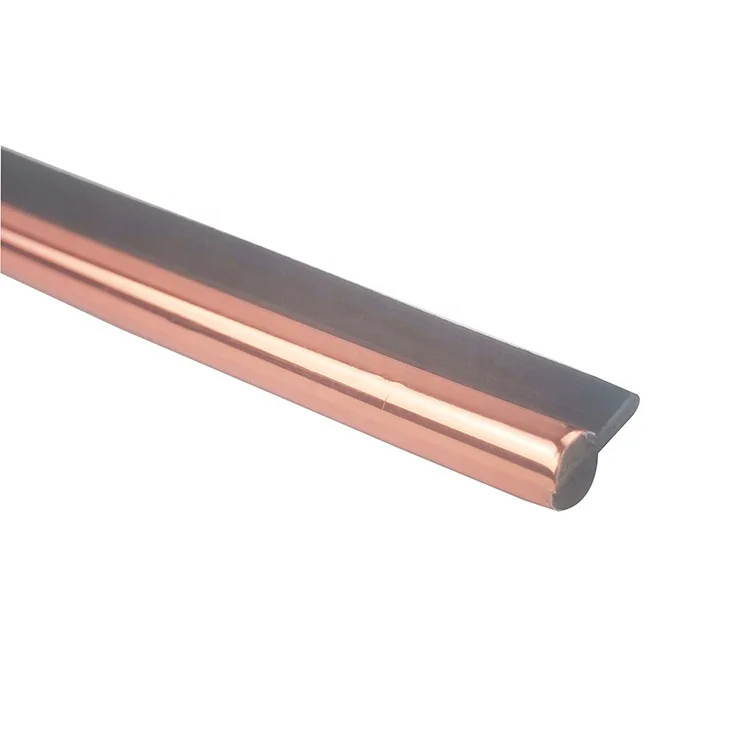

ce cetification epdm sponge seal

4. Performance Reliability Certifications often correlate with improved performance. For instance, seals that comply with industry standards for temperature and pressure resistance help prevent leaks and improve the lifespan of products. This is especially crucial in sectors like automotive and aerospace, where reliability is non-negotiable.

Applications of EPDM Sponge Seals

The versatility of EPDM sponge seals allows them to be integrated into numerous applications

1. Automotive Industry EPDM sponge seals are commonly used in vehicles for weather stripping, door seals, and vibration dampening. Their resilience to varying temperatures and corrosive elements ensures a longer lifespan, which is vital in automotive design.

2. Construction In construction, EPDM seals are utilized for insulation, soundproofing, and preventing water ingress. The material’s ability to withstand UV radiation and extreme weather conditions makes it an excellent choice for exterior applications.

3. HVAC Systems In heating, ventilation, and air conditioning systems, the effective sealing of joints and ductwork is essential. EPDM sponge seals provide a reliable barrier against air leakage, contributing to energy efficiency and maintaining temperature control.

4. Electronics In electronics, where moisture control is crucial, EPDM sponge seals can protect sensitive components from humidity, dust, and other contaminants.

Conclusion

Certification of EPDM sponge seals is more than just a stamp of approval; it represents a commitment to quality, safety, and environmental responsibility. As industries continue to evolve, the demand for reliable sealing solutions will grow, making certified EPDM sponge seals an indispensable resource. Companies that invest in certification not only enhance their product offerings but also build trust with their customers, paving the way for innovation and sustainable development in multiple sectors. Therefore, understanding and prioritizing certification in the usage of EPDM sponge seals is vital for success in any industry relying on effective sealing solutions.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025