curved shower door seal strip factories

Nov . 20, 2024 02:34 Back to list

curved shower door seal strip factories

Exploring the Production of Curved Shower Door Seal Strips A Dive into Factories

In the realm of modern bathroom design, the significance of functionality and aesthetics is paramount. One of the crucial components contributing to both elements is the curved shower door seal strip. Designed to provide a watertight barrier while enhancing the overall look of the shower enclosure, these seal strips are an integral part of shower door systems. This article delves into the factories that specialize in the manufacturing of curved shower door seal strips, highlighting their processes, challenges, and innovations.

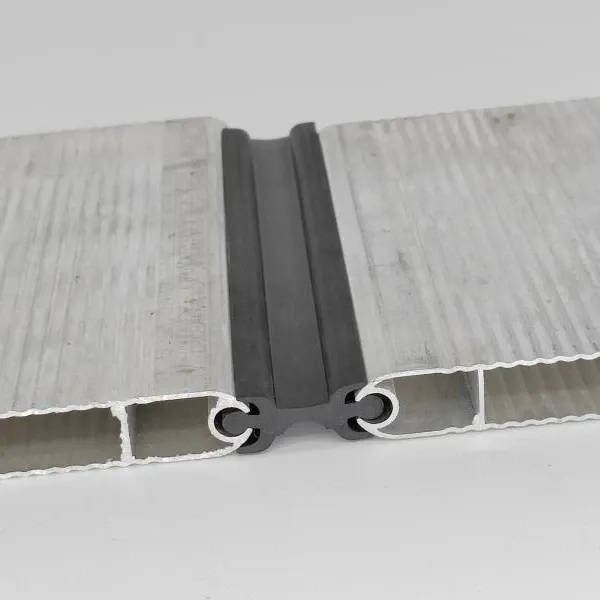

Curved shower door seal strips are typically made from high-quality materials such as silicone, rubber, or PVC. These materials are selected for their durability, flexibility, and resistance to mold and mildew, making them ideal for humid bathroom environments. The manufacturing process begins with the careful selection of raw materials. Factories often source high-grade materials from reputable suppliers to ensure that their products meet industry standards.

Once the materials are procured, factories employ advanced machinery to mold and shape the seal strips. The production process often involves extrusion, where heated material is forced through a die to create long strips that can be cut to size. This ensures consistency in product dimensions and quality. Quality control is integral at this stage, with rigorous testing carried out to ensure that the seal strips can withstand temperature variations and maintain their elasticity over time.

curved shower door seal strip factories

One of the challenges faced by manufacturers of curved shower door seal strips is the need for customization. Shower designs can vary significantly, requiring different shapes and sizes of seal strips. Factories often utilize computer-aided design (CAD) software to create prototypes tailored to specific client requirements. This not only streamlines the production process but also allows for quick adjustments, ensuring that the end products seamlessly fit different shower enclosures.

In addition to customization, sustainability is becoming increasingly important in the manufacturing of curved shower door seal strips. Many factories are adopting eco-friendly practices by using recyclable materials and minimizing waste during production. Some are even exploring biodegradable alternatives, responding to consumer demand for environmentally responsible products.

The competitive landscape of the curved shower door seal strip market has also spurred innovation. Factories are investing in research and development to create new formulations that enhance performance, such as increased UV resistance and improved adhesion properties. This drive for innovation is crucial as manufacturers strive to meet the evolving needs of consumers who prioritize both durability and style.

In conclusion, the production of curved shower door seal strips is a complex process involving careful material selection, advanced manufacturing techniques, and a commitment to quality and sustainability. As factories continue to innovate and adapt to market demands, they play a vital role in enhancing the functionality and aesthetics of modern bathrooms. By focusing on both performance and design, these manufacturers contribute significantly to creating a comfortable and appealing shower experience for consumers worldwide.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025