door and window sealing strip factories

Nov . 22, 2024 15:10 Back to list

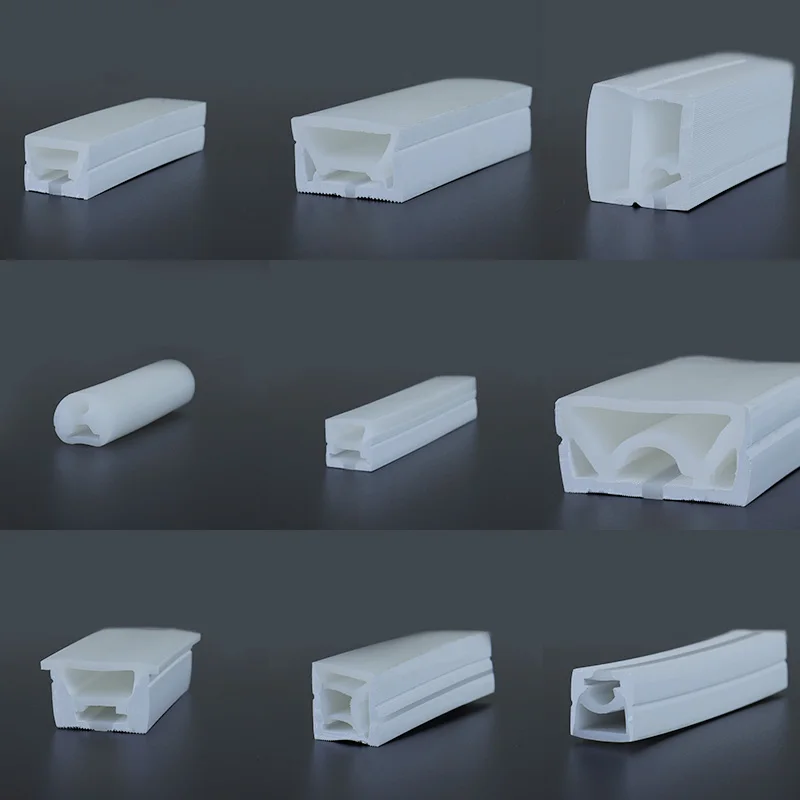

door and window sealing strip factories

The Importance of Door and Window Sealing Strips A Guide to Quality Manufacturing

As the seasons change, so do the needs of our homes and businesses. One critical yet often overlooked component of maintaining a comfortable and efficient indoor climate is the proper sealing of doors and windows. The role of door and window sealing strips cannot be understated, as they provide essential insulation, reduce energy costs, and enhance the overall comfort of spaces. This article explores the importance of these sealing strips, the manufacturing processes involved, and what to consider when selecting a factory for sourcing high-quality products.

Understanding Door and Window Sealing Strips

Door and window sealing strips are designed to prevent air infiltration and water leakage, which can lead to significant energy losses and potential damage to structures. These strips are typically made from various materials, including rubber, silicone, foam, and vinyl, each offering unique properties and benefits. Properly sealing doors and windows can reduce heating and cooling costs, improve indoor air quality, and minimize noise pollution from outside.

The Manufacturing Process

The production of sealing strips involves several key steps to ensure quality and durability. Initially, manufacturers select the appropriate raw materials based on the desired characteristics of the sealing strip. For instance, a rubber sealing strip might be ideal for outdoor use due to its weather-resistant properties, while foam may be better suited for indoor applications.

1. Material Preparation The raw materials are prepared and mixed according to specific formulas. This process is crucial, as the right combination of ingredients affects the performance of the final product.

2. Forming Once the materials are prepared, they are shaped into strips through extrusion or molding. Extrusion involves forcing the material through a die to create uniform strips, while molding can produce more complex shapes.

3. Curing The formed strips then undergo a curing process, typically involving heat or chemical treatment, which enhances their strength and elasticity.

4. Quality Control After curing, the strips are rigorously tested for durability, flexibility, and resistance to environmental factors like UV rays, moisture, and temperature fluctuations. This step is critical to ensure that the products meet industry standards and customer expectations.

door and window sealing strip factories

5. Packaging and Distribution Finally, the sealing strips are packaged for shipment. Manufacturers often provide detailed specifications and installation instructions, allowing consumers to make informed decisions.

Choosing the Right Factory

When considering a factory for door and window sealing strips, several factors come into play

1. Quality Assurance Look for manufacturers with robust quality control processes in place. Certifications such as ISO can be indicators of a factory's commitment to high-quality standards.

2. Material Options A reputable factory should offer a variety of materials to cater to different applications. This flexibility ensures that you can find the perfect sealing strip for your specific needs.

3. Customization Depending on your project, you may require customized solutions. Factories that can provide tailored products based on your specifications will be valuable partners.

4. Production Capacity Assess whether the factory has the capacity to meet your demands, especially for large projects. Efficient production methods and adequate inventory can help reduce lead times.

5. Customer Support Reliable customer service can make a significant difference, particularly if you encounter issues during installation or have questions about the products.

Conclusion

Investing in high-quality door and window sealing strips manufactured by reputable factories is essential for maintaining energy efficiency and comfort in both residential and commercial spaces. As consumers become increasingly aware of the benefits of proper insulation and weatherproofing, the demand for high-quality sealing solutions continues to grow. By understanding the importance of these products and the manufacturing processes involved, alongside making informed choices about sourcing, individuals and businesses can ensure they are equipped with the best sealing solutions for their needs. In doing so, they contribute to a more energy-efficient and comfortable future, while also protecting their investments in property and infrastructure.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025