Factory for High-Quality Door Brush Seal Strips to Enhance Your Home's Efficiency

Dec . 10, 2024 00:44 Back to list

Factory for High-Quality Door Brush Seal Strips to Enhance Your Home's Efficiency

The Importance of Door Brush Seal Strip Factories

In the world of construction and home improvement, sealing doors and windows is a critical aspect that often goes unnoticed. The quality of seals directly impacts energy efficiency, noise reduction, and overall comfort within a space. Among various sealing solutions, door brush seal strips have gained popularity due to their effectiveness and versatility. This article delves into the significance of door brush seal strip factories, the manufacturing processes involved, their benefits, and future prospects in the industry.

Understanding Door Brush Seal Strips

Door brush seal strips are specially designed components that are installed at the edges of doors to block drafts, dust, and sound. They consist of a brush-like material, typically made from nylon or polyester bristles, attached to a flexible backing. This design allows the strip to conform closely to the door frame, filling gaps effectively. The primary function of these seals is to enhance insulation, thus improving energy efficiency and reducing heating and cooling costs.

The Manufacturing Process

Door brush seal strip factories are equipped with advanced machinery and skilled personnel to ensure the high-quality production of these essential components. The manufacturing process typically involves several stages

1. Material Selection Factories use high-grade materials that can withstand wear and tear while providing superior insulation. This includes durable bristles and resilient backing materials, often made from rubber or foam.

2. Cutting and Shaping Once the materials are selected, they are cut into specific lengths and shapes according to predefined standards. Precision is crucial at this stage to ensure proper fit and function.

3. Assembly The cutting and shaping components are then assembled. The bristles are usually attached to the backing using adhesive or stitching, depending on the design requirements. This stage requires meticulous attention to detail to guarantee that the seals are both effective and aesthetically pleasing.

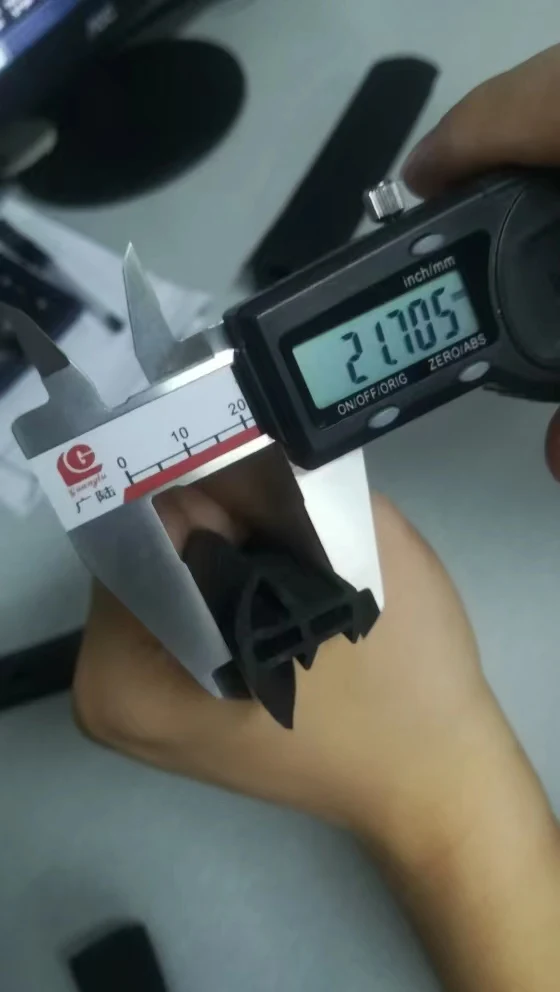

4. Quality Control After assembly, each batch of door brush seal strips undergoes rigorous quality control testing. This includes checking for durability, flexibility, and overall performance. Factories strive to meet international quality standards to satisfy customer expectations.

5. Packaging and Distribution Once products pass quality control, they are packaged for distribution. Factories often use eco-friendly packaging to align with sustainability trends and to appeal to environmentally conscious consumers.

door brush seal strip factory

Benefits of Door Brush Seal Strips

The adoption of door brush seal strips in homes and commercial buildings offers numerous advantages

- Energy Efficiency These seals help to maintain desired indoor temperatures, thus reducing the load on heating and cooling systems. This not only leads to lower energy bills but also lessens environmental impact.

- Noise Reduction Installing brush seals can significantly dampen sound transmission, making spaces quieter and more conducive to relaxation or work.

- Dust and Pest Control By blocking gaps, door brush seal strips prevent dust accumulation and deter pests from entering buildings, contributing to a cleaner and healthier indoor environment.

- Versatility Available in various sizes and styles, door brush seal strips can be used on different types of doors, including residential, commercial, and industrial doors.

The Future of Door Brush Seal Strip Factories

As the demand for sustainable building practices continues to grow, door brush seal strip factories are positioned to expand. Innovations in materials, such as recycled plastics and biodegradable options, are likely to emerge, aligning with global sustainability goals. Additionally, technological advancements in manufacturing processes may lead to higher efficiency and lower production costs.

Moreover, as energy conservation becomes a more pressing issue, the importance of effective sealing products will only increase, driving further growth in this sector. Factories that embrace eco-friendly practices and invest in research and development will likely lead the market.

Conclusion

Door brush seal strip factories play a crucial role in enhancing the quality and sustainability of buildings. By focusing on quality manufacturing and innovation, these factories not only contribute to energy efficiency and comfort but also respond to the growing demand for environmentally friendly products. As we look to the future, the importance of effective sealing solutions will continue to grow, benefiting both consumers and the planet.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025