Manufacturer of Durable, High-Strength Flexible Materials for Various Applications

Nov . 30, 2024 17:29 Back to list

Manufacturer of Durable, High-Strength Flexible Materials for Various Applications

Durable, High Strength, and Flexibility An Insight into Modern Manufacturing

In an age where performance and durability are key concerns for consumers, the manufacturing industry has evolved to meet these demands by focusing on the development of durable, high-strength, and flexible materials. These characteristics are not merely desirable but essential in various sectors, including automotive, aerospace, construction, and consumer goods. This article delves into the importance of these properties in manufacturing and how leading manufacturers are innovating to create products that excel in these areas.

Understanding the Need for Durability Durability is a critical aspect that consumers and businesses alike look for in products. It refers to the ability of a material to withstand wear, pressure, or damage. In today's market, where sustainability is increasingly important, durable products not only lower the cost of ownership by reducing the need for replacements but also contribute to environmental conservation by minimizing waste.

Many modern manufacturing processes focus on utilizing materials that exhibit superior durability. For instance, advanced polymers, composite materials, and specialized metals are engineered to enhance their lifespan and performance. Manufacturers are investing in research and development to innovate new materials that can endure extreme conditions, whether it’s the heat of an engine or the stress of heavy loads in construction.

The Importance of High Strength High strength materials are vital for applications where safety and reliability are paramount. In sectors like aerospace and automotive, the materials used must not only support their weight but also endure high-stress conditions. High tensile strength materials, such as carbon fiber and certain alloys, are crucial for constructing aircraft wings and vehicle frames. These materials allow for lighter designs, which contribute to improved fuel efficiency and performance.

Leading manufacturers in this field are adopting technologies such as 3D printing and nanotechnology to create materials that are both strong and lightweight. By manipulating the structure of materials at the molecular level, manufacturers can produce components that offer enhanced performance without compromising on durability.

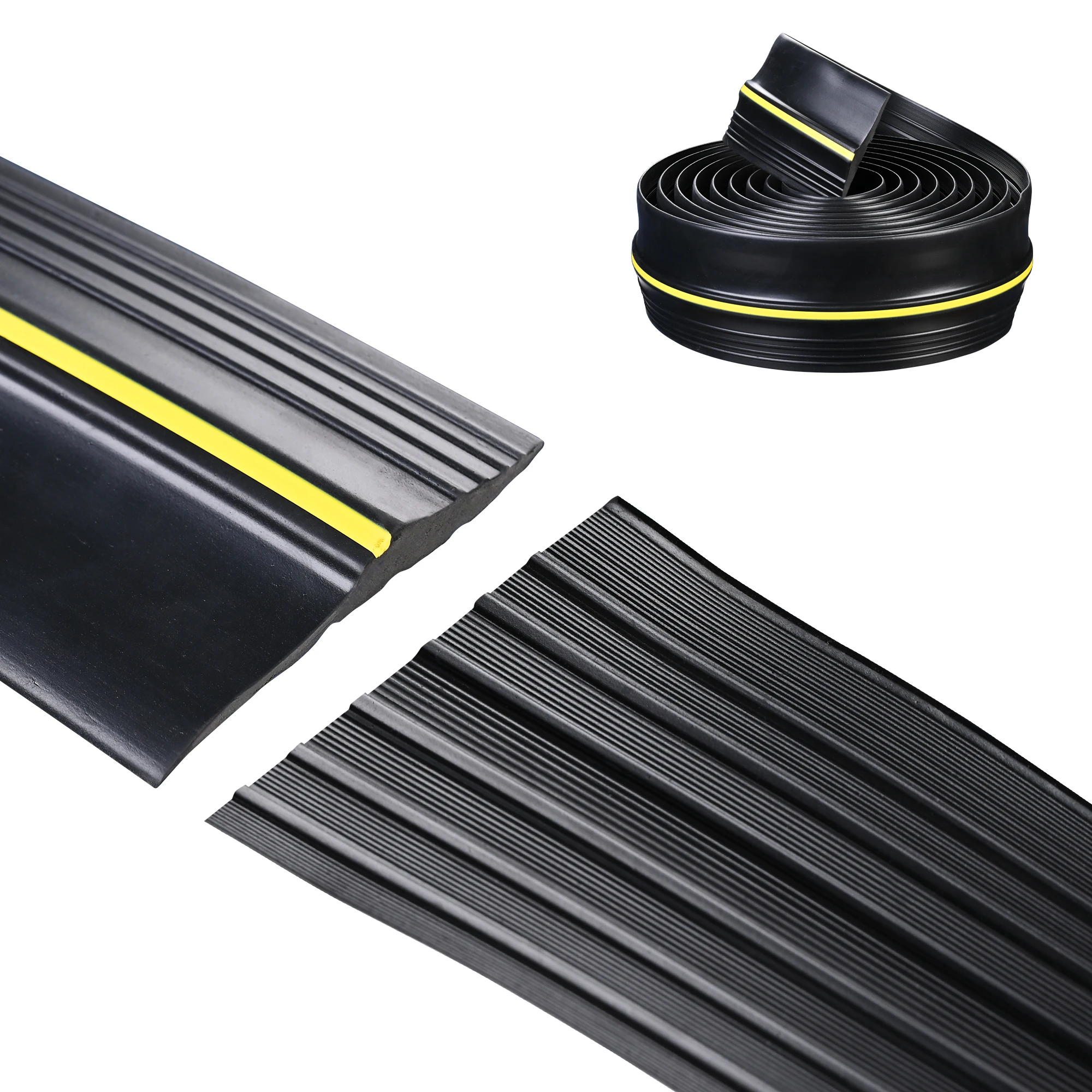

durable, high strength and flexibility manufacturer

Flexibility in Manufacturing While strength and durability are essential, flexibility is another characteristic that cannot be overlooked. In manufacturing, flexibility refers to the ability of materials to deform without breaking. This property is vital for applications where materials must adapt to various stressors, including tension, compression, and bending.

Flexible materials are especially important in industries that require components to undergo significant motion. For instance, in the automotive industry, flexible materials are used in suspension systems to absorb shocks and provide a smooth ride. In the world of consumer electronics, flexible circuits are becoming increasingly common, enabling the development of bendable screens and compact designs.

Manufacturers are leveraging advancements in materials science to enhance the flexibility of their products. New elastomers and flexible composites are being designed to not only hold up under pressure but also to return to their original shape after deformation. This balance of flexibility and strength is crucial for developing high-performance products.

Conclusion As the manufacturing landscape continues to evolve, the focus on creating durable, high-strength, and flexible materials remains at the forefront. Manufacturers recognize that meeting these demands is essential for maintaining competitiveness in a global market that prioritizes performance and sustainability.

The innovations in materials science, engineering, and technology have paved the way for a new era of manufacturing, where products are not only built to last but are also adaptable to the varying needs of consumers and industries. With continued investment in research and development, the future looks promising, where durable, high-strength, and flexible products will revolutionize the way we interact with the world around us.

As we move forward, it is clear that the collaboration between manufacturers, researchers, and consumers will play a crucial role in shaping the products of tomorrow—products that are not only functional but also sustainable and environmentally friendly. By prioritizing these attributes, the manufacturing industry is well on its way to creating a better and more efficient future.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025